Preparing method of nanometer instant fishbone meal

A fish bone meal, fish bone technology, applied in the direction of bacteria, food science, application, etc. used in food preparation, to achieve the effects of improving solubility and water holding capacity, increasing the content of free calcium, and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

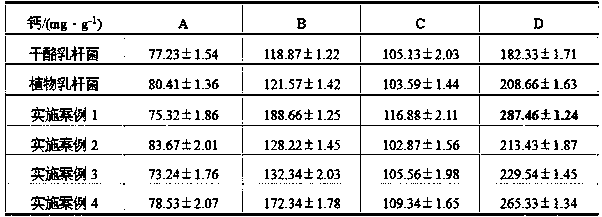

Examples

Example Embodiment

[0020] Example 1

[0021] 1. Fully clean the leftovers of Balang fish bones, and soak the fish bones in 40% sodium carbonate solution for 40 minutes according to the solid-to-liquid ratio of fish bones and sodium carbonate solution of 1g:3mL, to remove the fishy smell and grease;

[0022] 2. Clean and dry the deodorized and degreased Balang fish bone again, use a ball mill for preliminary dry crushing, pass through a 200-mesh sieve, add water 3 times the quality of the fish bone powder to dilute, stir evenly, and obtain fish bone paste ;

[0023] 3. Adjust the temperature of the fish bone paste to 35°C, and add the compound fermentation bacteria (Lactobacillus casei ( Lactobacillus casei ) with plant milk bacteria ( Lactobacillus plantarum ) was compounded according to the mass ratio of 2:1) for 1.5 h of biological fermentation and enzymolysis, and the pH value of the fermentation system was 7.0;

[0024] 4. After the enzymatic hydrolysis, use a dynamic high-pressure micro-

Example Embodiment

[0028] Example 2

[0029] 1. Fully clean the leftovers of balang fish bones, and soak the fish bones in 40wt.% sodium carbonate solution for 30 minutes according to the solid-liquid ratio of fish bones and sodium carbonate solution 1g:2mL, to remove the fishy smell and grease;

[0030] 2. Clean and dry the deodorized and degreased Balang fish bone again, use a ball mill for preliminary dry crushing, pass through a 200-mesh sieve, add water 3 times the quality of the fish bone powder to dilute, stir evenly, and obtain fish bone paste ;

[0031] 3. Adjust the temperature of the fish bone paste to 40°C, and add the compound fermentation bacteria (Lactobacillus casei ( Lactobacillus casei ) with plant milk bacteria ( Lactobacillus plantarum ) was compounded according to the mass ratio of 2:0.5) for 0.5 h of biological fermentation and enzymolysis, and the pH value of the fermentation system was 7.0;

[0032] 4. After the enzymatic hydrolysis, use a dynamic high-pressure micro-f

Example Embodiment

[0036] Example 3

[0037]1. Fully clean the leftovers of balang fish bones, and soak the fish bones in 40wt.% sodium carbonate solution for 40 minutes according to the solid-liquid ratio of fish bones and sodium carbonate solution 1g:3mL, to remove the fishy smell and grease;

[0038] 2. Clean and dry the deodorized and degreased Balang fish bone again, use a ball mill for preliminary dry crushing, pass through a 200-mesh sieve, add water 3 times the quality of the fish bone powder to dilute, stir evenly, and obtain fish bone paste ;

[0039] 3. Adjust the temperature of the fish bone paste to 35°C, and add the compound fermentation bacteria (Lactobacillus casei ( Lactobacillus casei ) with plant milk bacteria ( Lactobacillus plantarum ) was compounded according to the mass ratio of 2:1) for 1.5 h of biological fermentation and enzymolysis, and the pH value of the fermentation system was 7.0;

[0040] 4. After the enzymatic hydrolysis, use a dynamic high-pressure micro-flui

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap