Engine reliability testing method, device and equipment and storage medium

A test method and engine technology, applied to the internal combustion engine test, etc., can solve the problems of high cost and long engine reliability test period, and achieve the effect of reducing test cost and shortening the test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

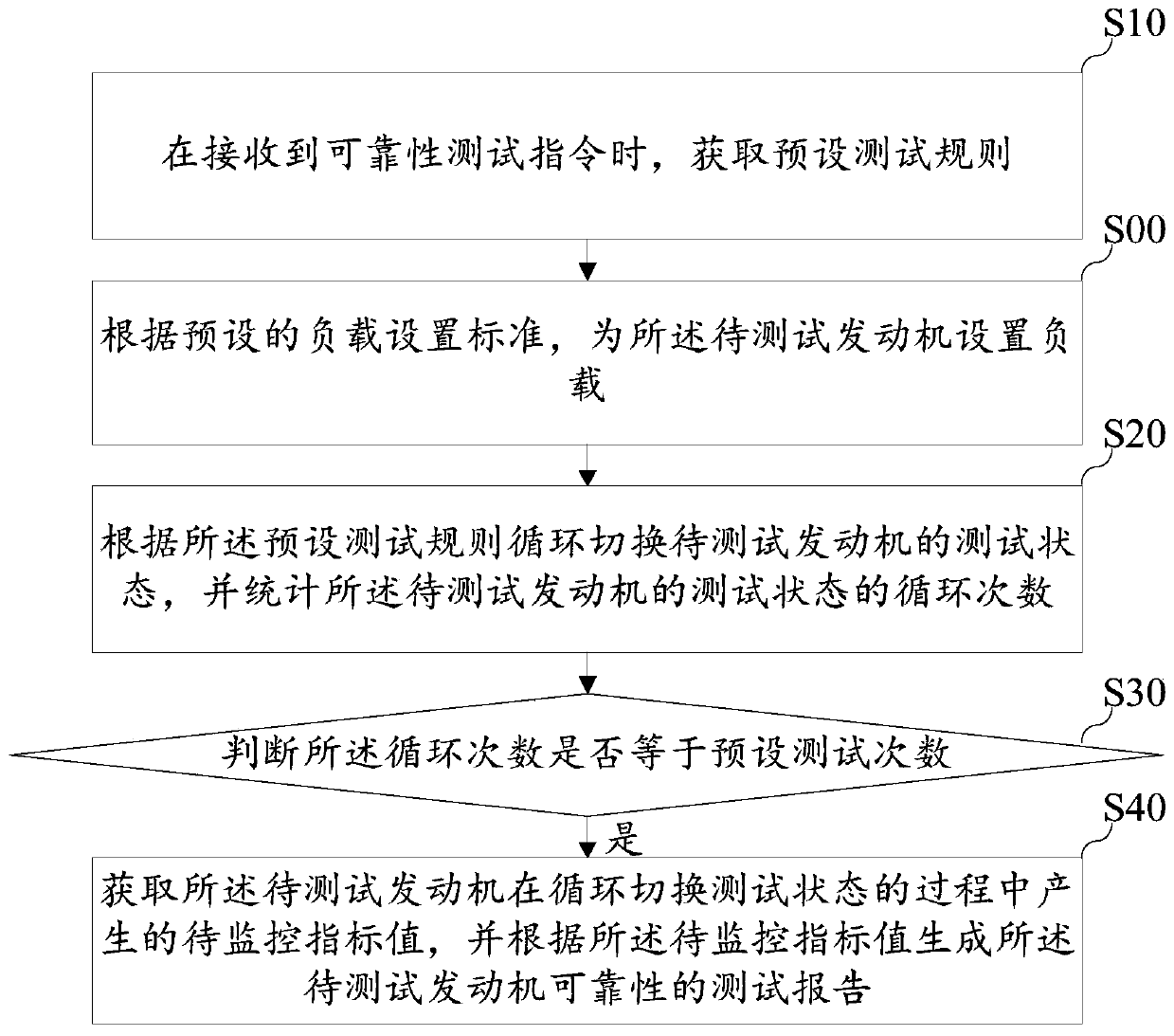

[0130] Based on the above-mentioned first embodiment, before the step S20, the engine reliability testing method of this embodiment further includes:

[0131] Step S00, setting the load for the engine to be tested according to the preset load setting standard.

[0132] Specifically, in order to ensure that the load set for the engine to be tested is as close as possible to the actual road conditions of the vehicle carrying the engine to be tested, the load borne by the engine to be tested, the load standard is preferably based on the vehicle carrying the engine to be tested. The actual operating state of the engine of the vehicle is determined.

[0133] It should be understood that, in practical applications, the load set for the engine to be tested may be the average effective pressure that the engine to be tested needs to withstand under different test conditions and different rotational speeds.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap