Polishing equipment for industrial machinery

A technology of industrial machinery and equipment, applied in the field of grinding equipment for industrial machinery, can solve the problems of large size of grinding equipment, insufficient product grinding accuracy, low grinding efficiency, etc., and achieve the effect of high grinding efficiency, high grinding precision and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

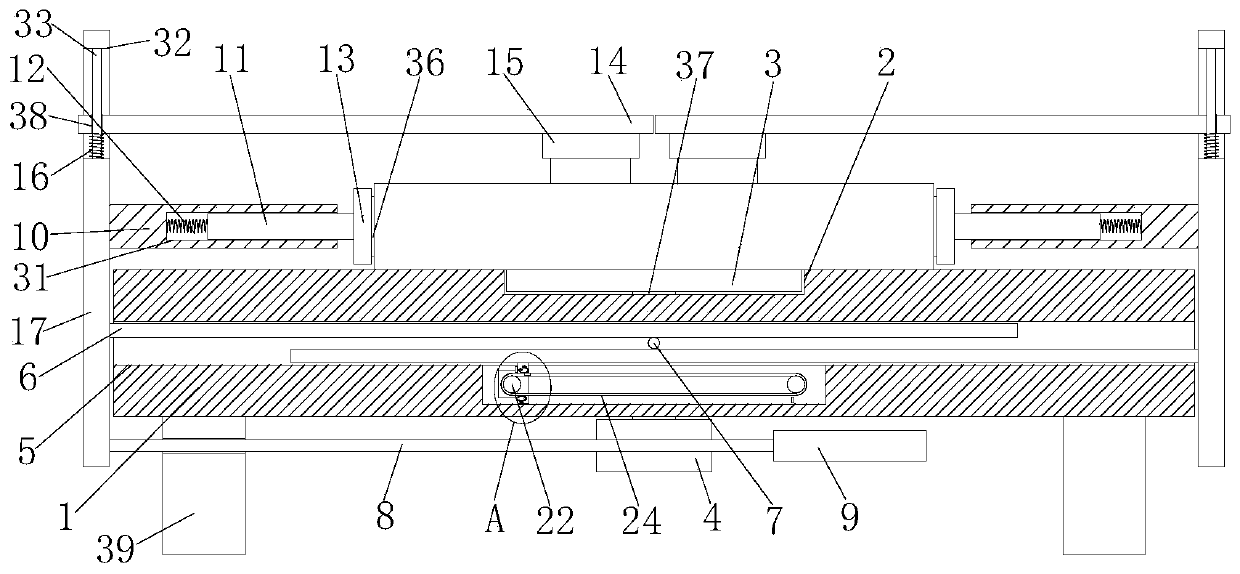

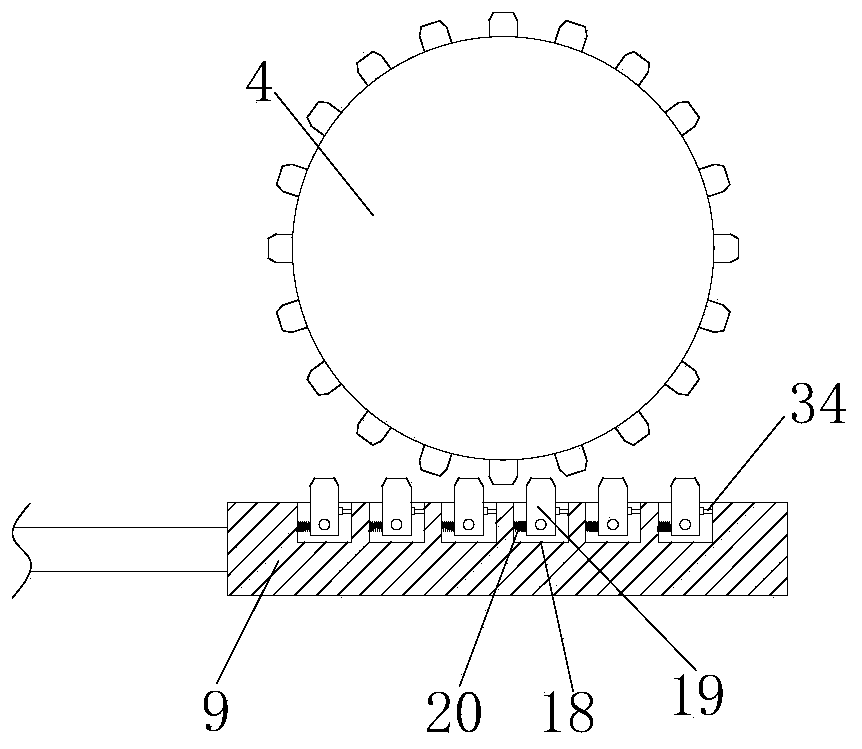

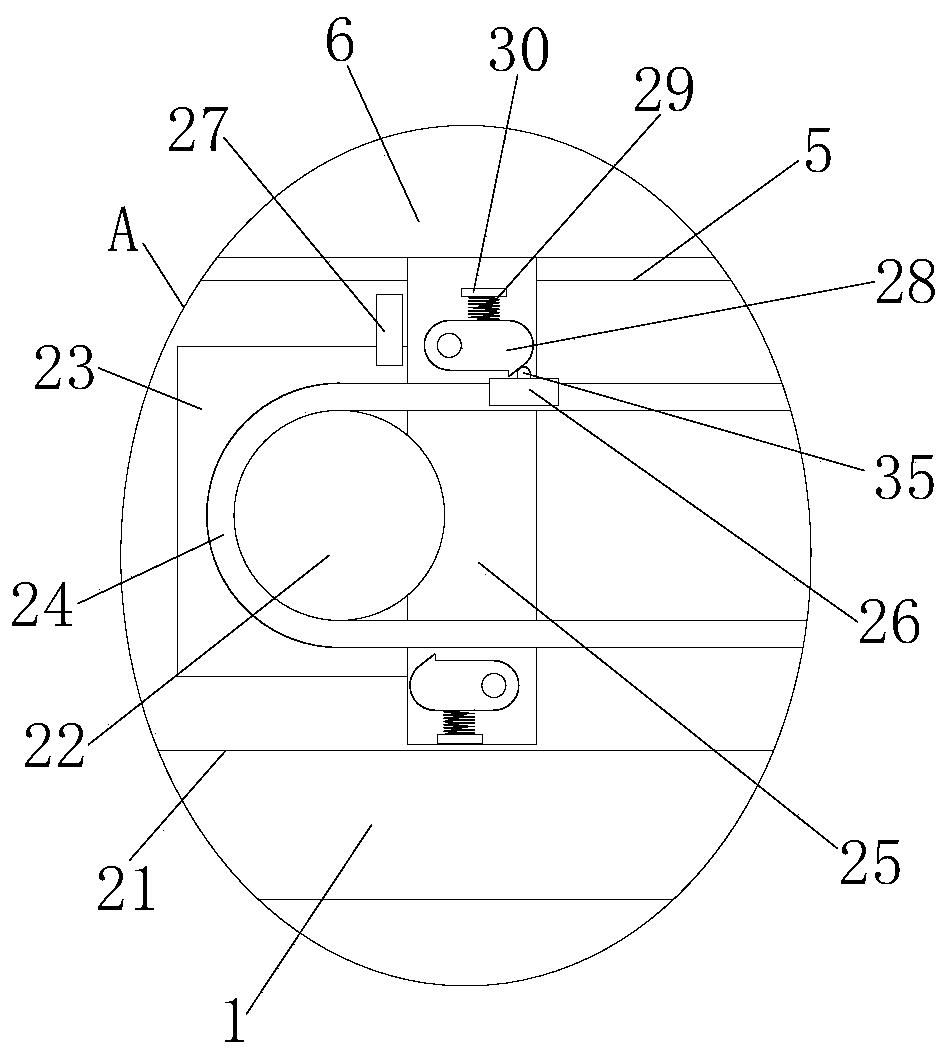

[0028] Reference Figure 1-5 , A polishing equipment for industrial machinery, including a polishing table 1, a plurality of columns 39 are fixedly installed at the bottom of the polishing table 1, a circular groove 2 is provided on the top of the polishing table 1, and a turntable 3 is rotatably installed in the circular groove 2. A grinding work piece is placed on the top of the turntable 3, and a rotating column 37 is fixedly installed on the bottom of the turntable 3. The bottom end of the rotating column 37 extends to the outside of the grinding table 1 and is fixedly installed with a first gear 4, and one side of the grinding table 1 is provided Two moving plates 6 are slidably installed in the fixed hole 5. The sides of the two moving plates 6 close to each other are fixedly installed with a rack, and the fixed hole 5 is rotatably installed with a second gear 7, two teeth The bars are all meshed with the second gear 7, the two moving plates 6 are fixedly i

Example Embodiment

[0037] Example 2

[0038] Reference Figure 1-5 , A polishing equipment for industrial machinery, including a polishing table 1, a plurality of columns 39 are fixedly installed at the bottom of the polishing table 1, a circular groove 2 is provided on the top of the polishing table 1, and a turntable 3 is rotatably installed in the circular groove 2. A grinding work piece is placed on the top of the turntable 3, and the bottom of the turntable 3 is fixedly installed with a rotating column 37 through bolts. The bottom end of the rotating column 37 extends to the outside of the grinding table 1 and is fixedly installed with a first gear 4 through bolts. One side is provided with a fixed hole 5, two moving plates 6 are slidably installed in the fixed hole 5, the sides of the two moving plates 6 that are close to each other are fixedly installed with a rack by bolts, and the second is rotatably installed in the fixed hole 5. Gear 7, two racks are meshed with the second gear 7, the side

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap