Multifunctional sunlight room installation lifting machine

A sun room and multi-functional technology, applied in the direction of portable lifting devices, cranes, hoisting devices, etc., can solve the problems of inconvenient transportation, inconvenient disassembly of small cranes, unusable lifting equipment, etc., to improve stability and reliability, Avoid uneven weight distribution, convenient and fast installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

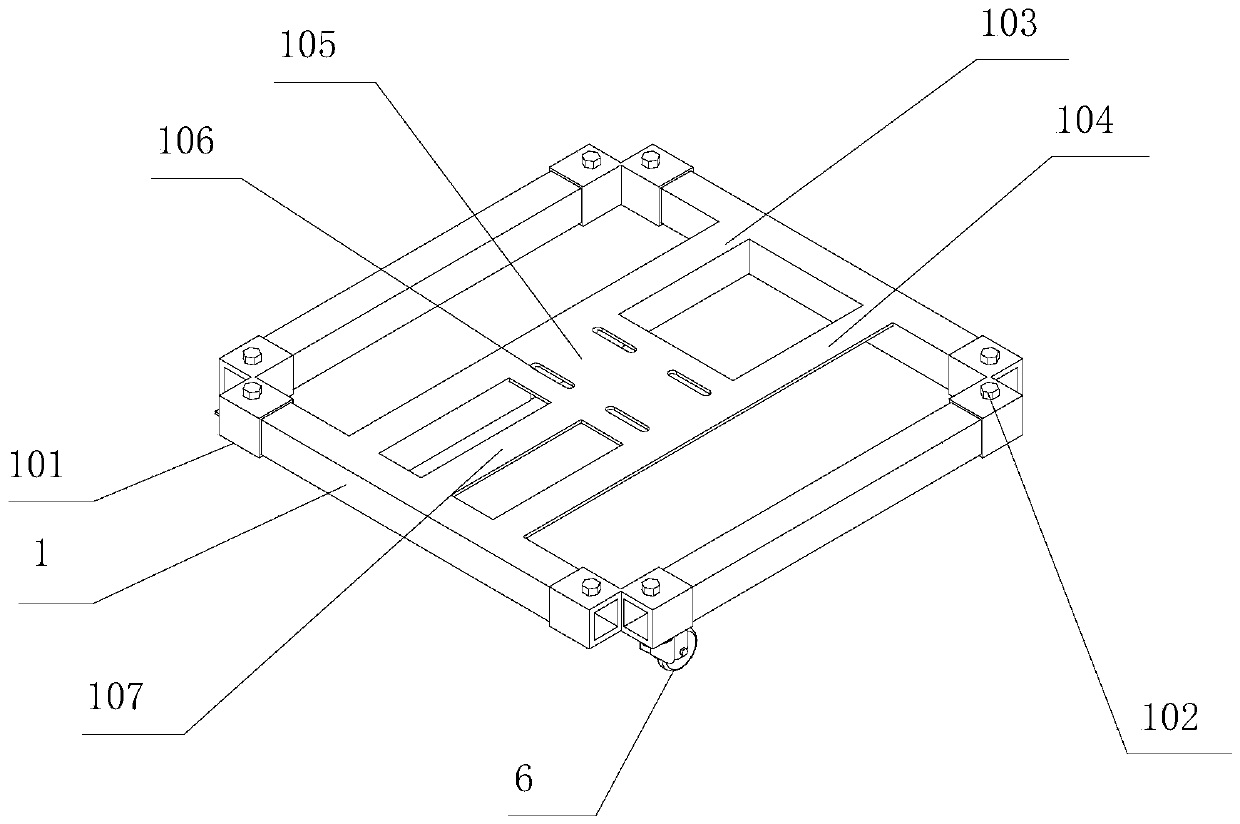

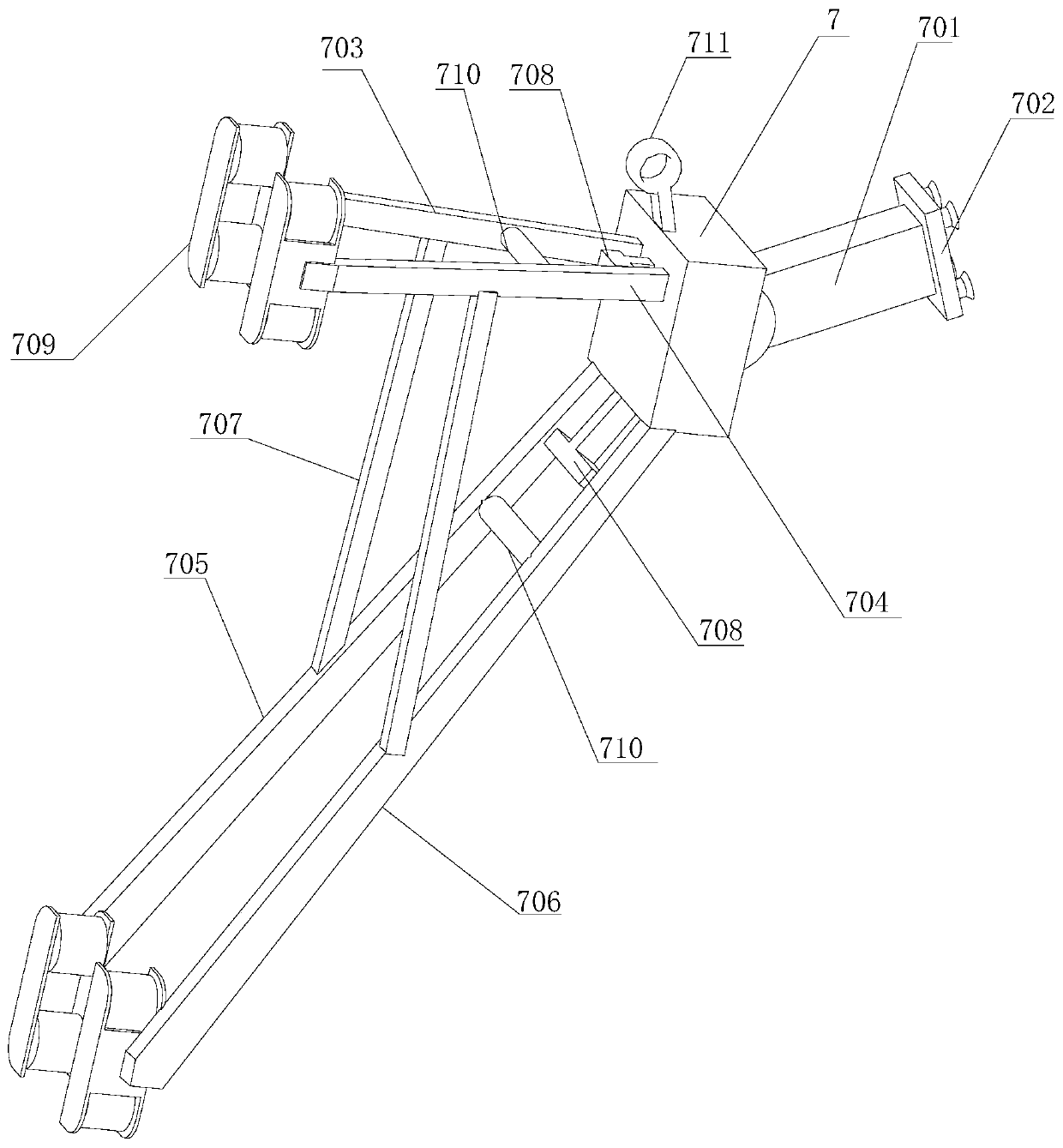

[0031] like Figure 1-7 As shown, the present invention includes a chassis, a column 3, an output steel rope I501 and a hoisting motor, and the chassis includes four square tubes 1 connected end-to-end, and the four square tubes 1 can be integrally formed or welded. , In order to facilitate production, the present invention preferably adopts welding connection, and four square tubes 1 with the same structure and size are welded to each other to reduce production cost. , the four corners of the four square tubes 1 are all convenient to set the extended support rod 2, which simplifies the installation difficulty of the extended support rod 2. The end of the square tube 1 is sleeved with the extended support rod 2, and the cross-sectional shape of the extended support rod 2 is The shape of the inner cavity of the square tube 1 is consistent; in order to facilitate the extension of the support rod 2 and the sleeve of the square tube 1, the extension support rod 2 and the square tube

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap