Frozen dough improver, frozen dough with the same, and preparing method and application

A technique for freezing dough and making methods, which is applied in the direction of dough handling, application, dough preparation, etc. It can solve the problems of low yeast activity and poor quality, achieve long shelf life, improve rheological properties, and reduce the effect of deterioration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

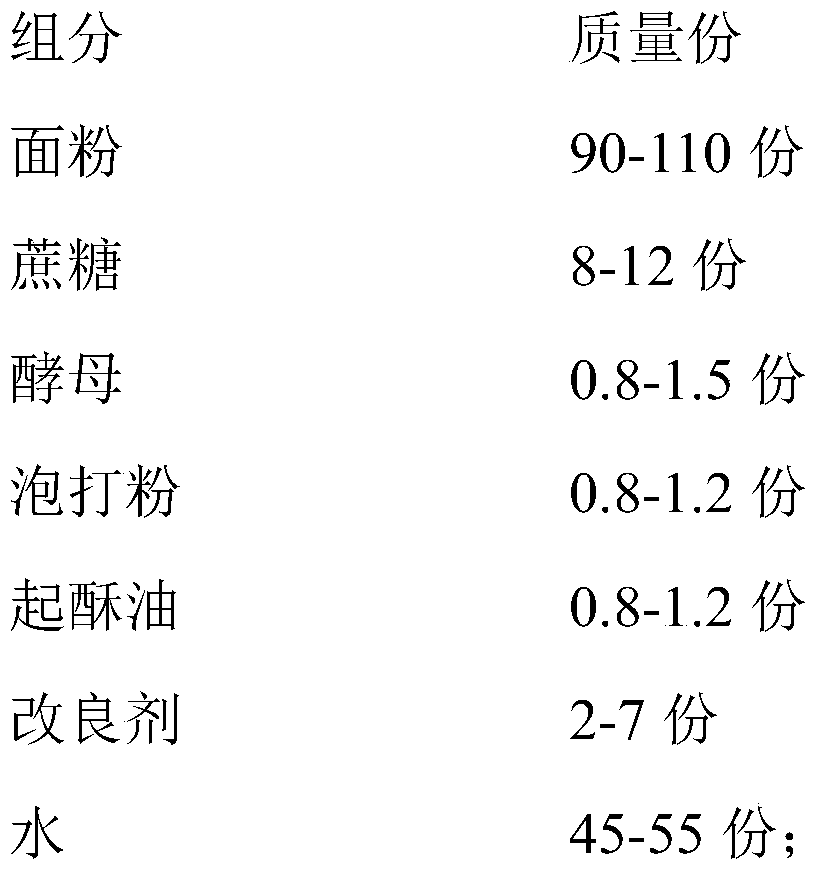

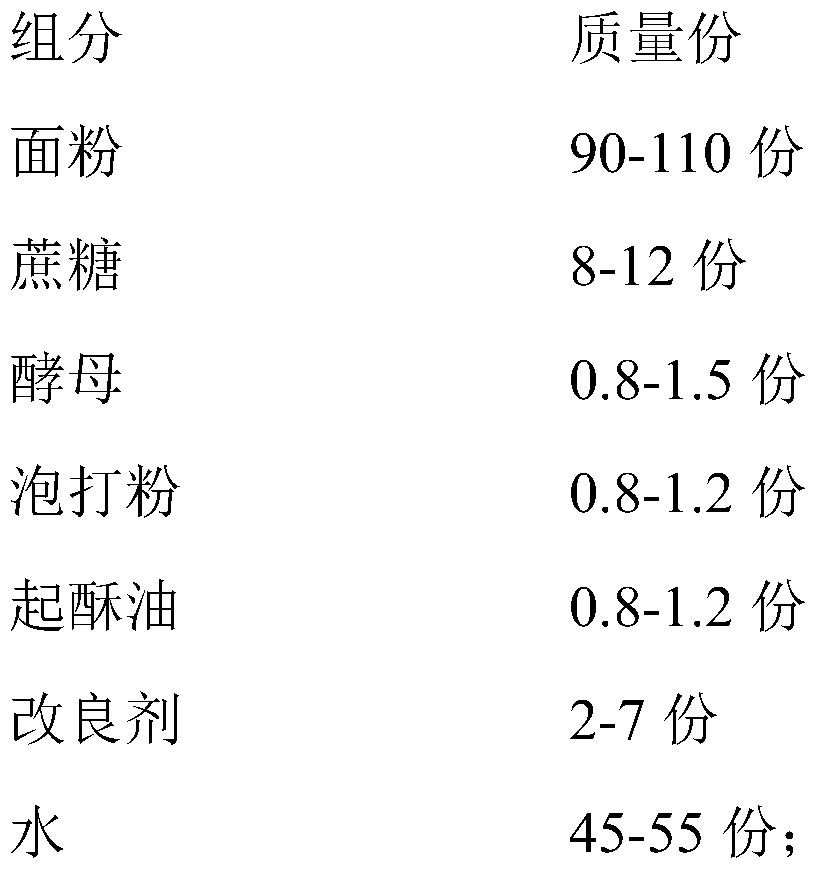

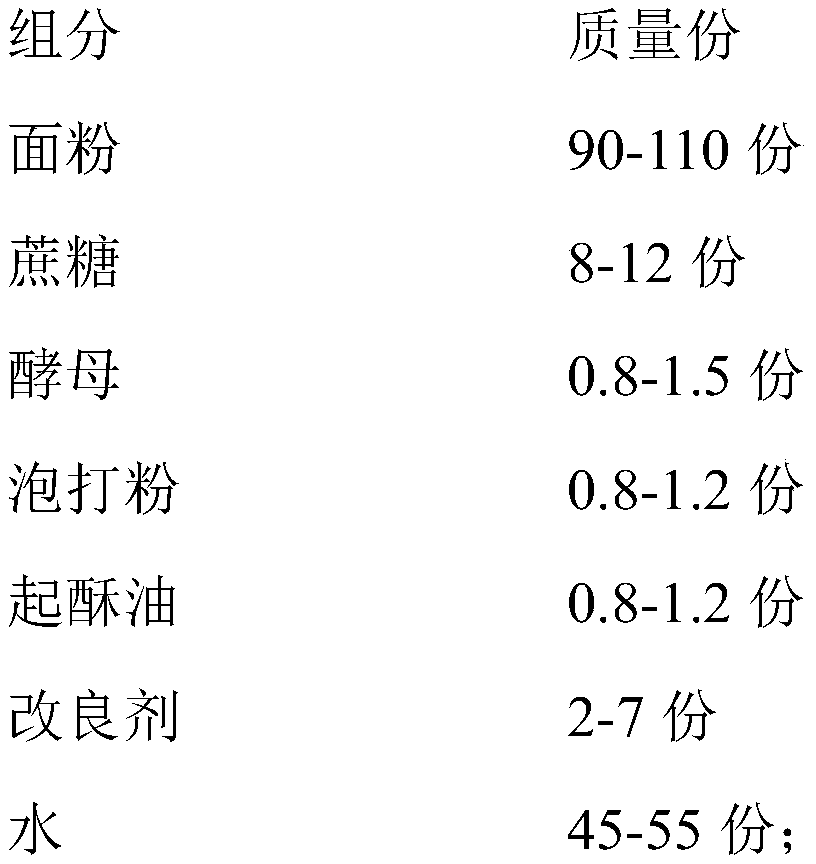

[0051] (1) Dissolve 12g of yeast in 500g of water to form a yeast aqueous solution, mix 100g of sucrose and 50g of improver evenly, dissolve in the yeast aqueous solution, and let it stand for 2 minutes to obtain a mixed solution A. Mix 10g of baking powder, 10g of shortening and 1000g of flour Mixed material B is uniformly obtained; wherein, the components in the improver are calculated by mass fraction: trehalose 94%, xanthan gum 1.2%, carboxymethyl cellulose sodium 0.9%, sodium dihydrogen phosphate 3.5%, and the balance is starch ;

[0052] (2) Pour the mixed liquid A and the mixed material B obtained in step (1) into the dough cylinder of the dough mixer and mix them, turn on the low gear to knead until the surface of the dough is smooth, and get dough C;

[0053] (3) After pressing the dough C obtained in step (2) for 6 times, roll it into a cylindrical shape and cut it into shape with a knife to obtain the raw steamed bun, put the raw steamed bun in a -35°C refrigerator for

Embodiment 2

[0056] (1) Dissolve 8g of yeast in 450g of water to form a yeast aqueous solution, mix 80g of sucrose and 70g of improver evenly and dissolve in the yeast aqueous solution, let it stand for 1min to obtain mixed solution A, mix 8g of baking powder, 8g of shortening and 900g of flour The mixed material B was uniformly obtained; wherein, the components in the improving agent were calculated by mass fraction: 96.2% trehalose, 0.8% xanthan gum, 0.6% sodium carboxymethylcellulose, and 2.4% sodium dihydrogen phosphate.

[0057] (2) Pour the mixed liquid A and the mixed material B obtained in step (1) into the dough cylinder of the dough mixer and mix them, turn on the low gear to knead until the surface of the dough is smooth, and get dough C;

[0058] (3) After pressing the dough C obtained in step (2) for 5 times, roll it into a cylindrical shape and cut it into shape with a knife to obtain the raw steamed buns, put the raw steamed buns in a -30°C refrigerator for quick freezing for 40

Embodiment 3

[0061] (1) Dissolve 15g of yeast in 550g of water to form a yeast aqueous solution, mix 120g of sucrose and 20g of improver evenly, dissolve in the yeast aqueous solution, and let it stand for 3 minutes to obtain mixed solution A. Mix 12g of baking powder, 12g of shortening and 1100g of flour Obtain the mixed material B evenly; wherein, the components in the improver are calculated by mass fraction: 89% trehalose, 2.2% xanthan gum, 1.8% sodium carboxymethyl cellulose, 6.7% sodium dihydrogen phosphate, and the balance is starch .

[0062] (2) Pour the mixed liquid A and the mixed material B obtained in step (1) into the dough cylinder of the dough mixer and mix them, turn on the low gear to knead until the surface of the dough is smooth, and get dough C;

[0063] (3) After pressing the dough C obtained in step (2) 8 times, roll it into a cylindrical shape and cut it into shape with a knife to obtain the raw steamed bun, put the raw steamed bun into a -40°C refrigerator for 60 minu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap