Automatic ejector pin spiral groove grinding device

A technology of grinding device and spiral groove, which is applied in the direction of tangent device, large fixed member, tangent machine, etc., can solve the problems of high cost of alloy tools, high cost of machine tools, time required, etc., to achieve low cost, improve production efficiency, clamping fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

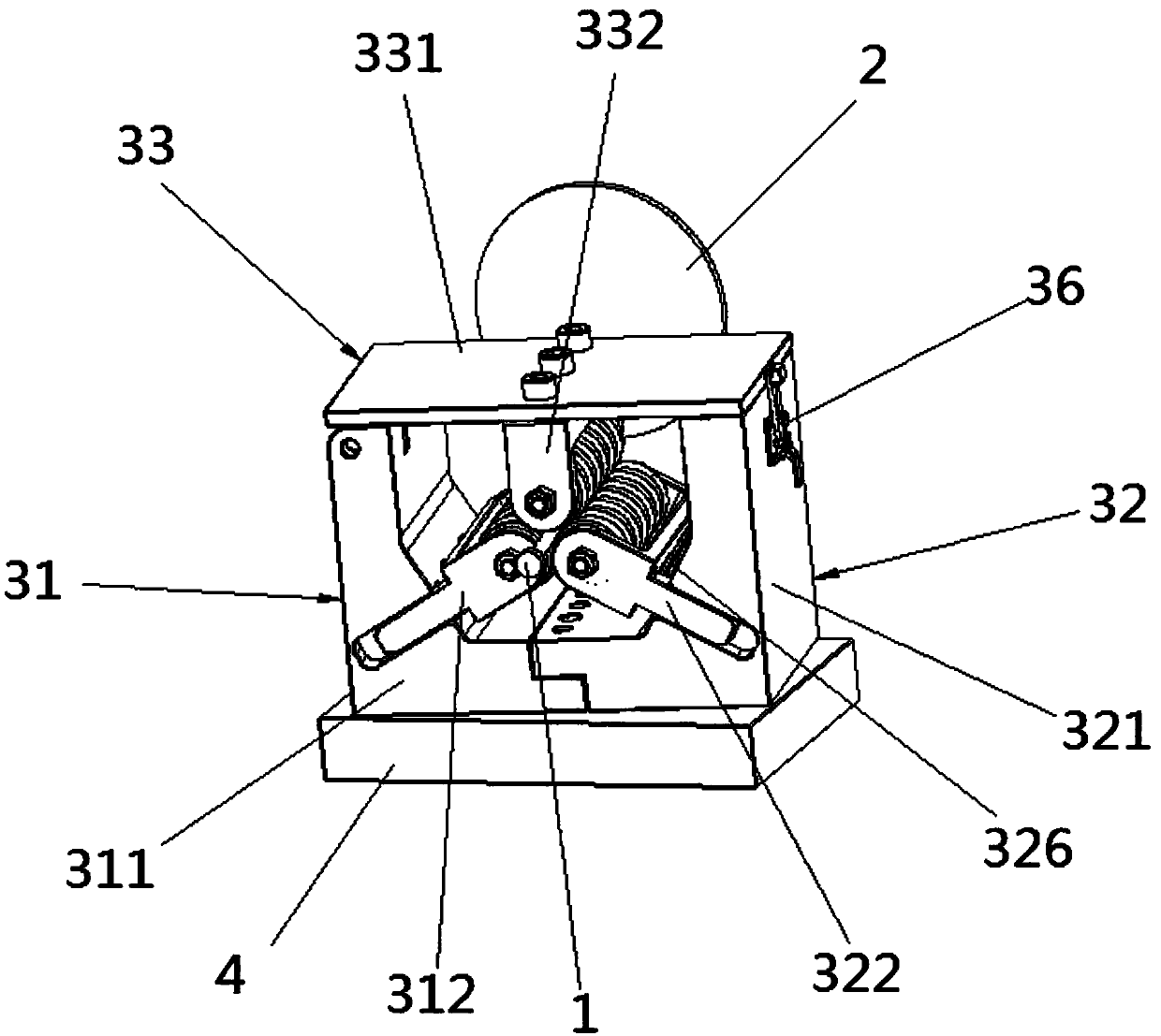

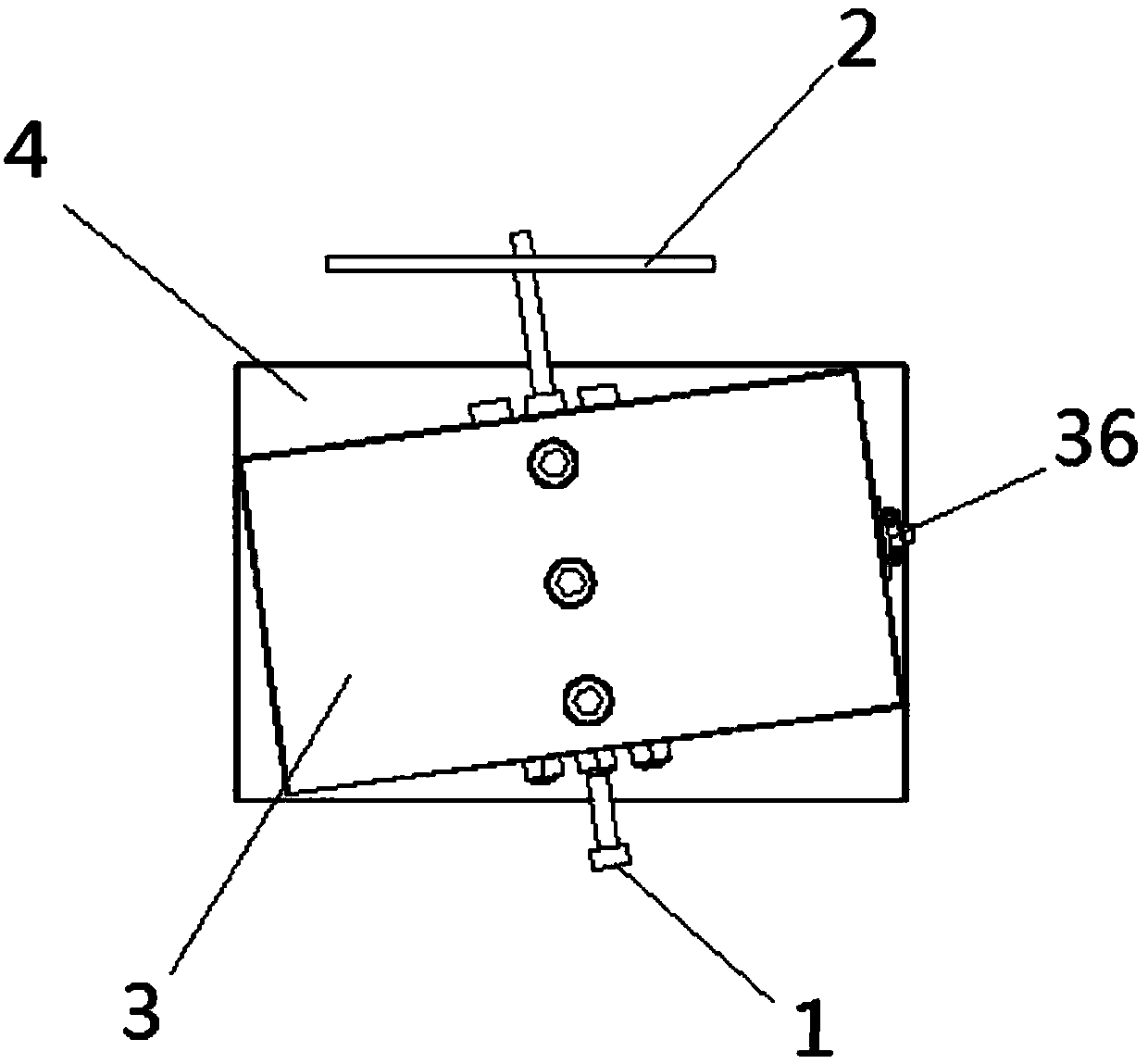

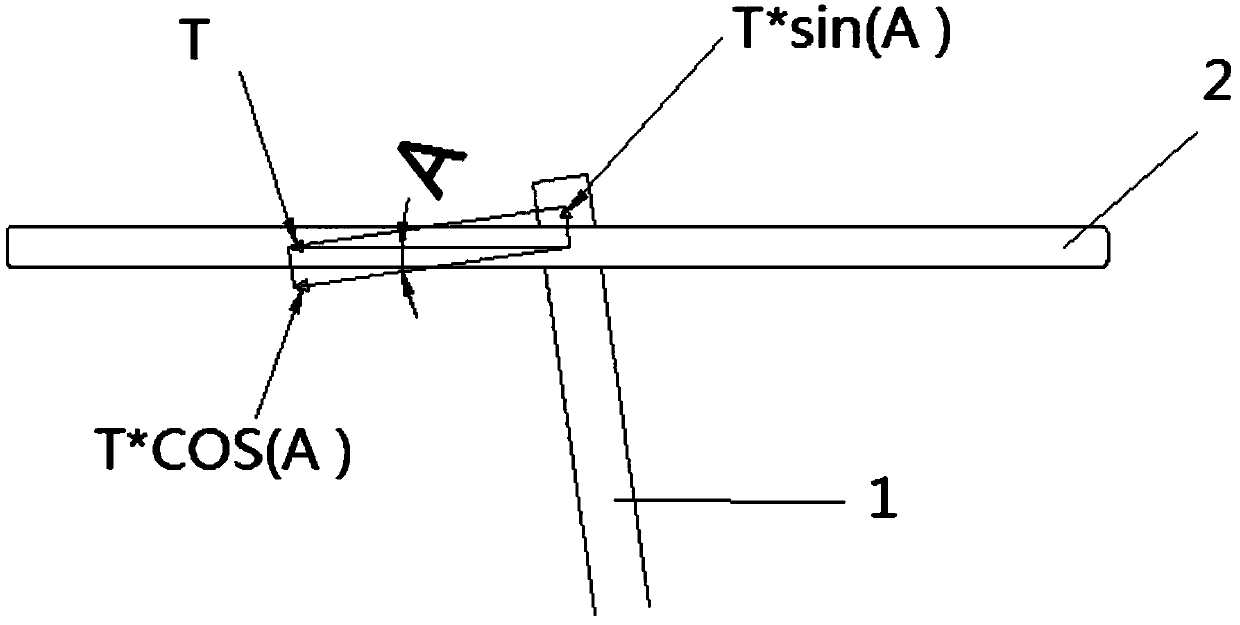

[0025] Such as Figure 1-2 As shown, the thimble spiral groove automatic grinding device of the present invention includes a cutting wheel 2 and a mounting seat 3 arranged in front of the cutting wheel 2 . Because the cutting wheel 2 only rotates clockwise and has no forward movement, and the thimble 1 needs to move in two directions to realize the processing of the spiral groove, that is, the rotational movement plus the forward movement. In order to give this forward force, it is necessary to place the thimble 1 at an angle A, such as image 3 As shown, the force T on the thimble 1 received by the cutting wheel 2 is counterclockwise. According to the decomposition of the force, two forces can be decomposed: the force T*sin(A) in the forward direction and the force T*cos in the counterclockwise direction. (A), so that the thimble 1 moves in these two

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap