Testing platform for purification material for removing multiple AMCs (airborne molecular contaminants)

A test platform and a technology for purifying materials, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as poor analysis of chemical photoresist liquid, abnormal wiring welding, and affecting chip line width process, etc., so as to achieve controllable gas generation , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

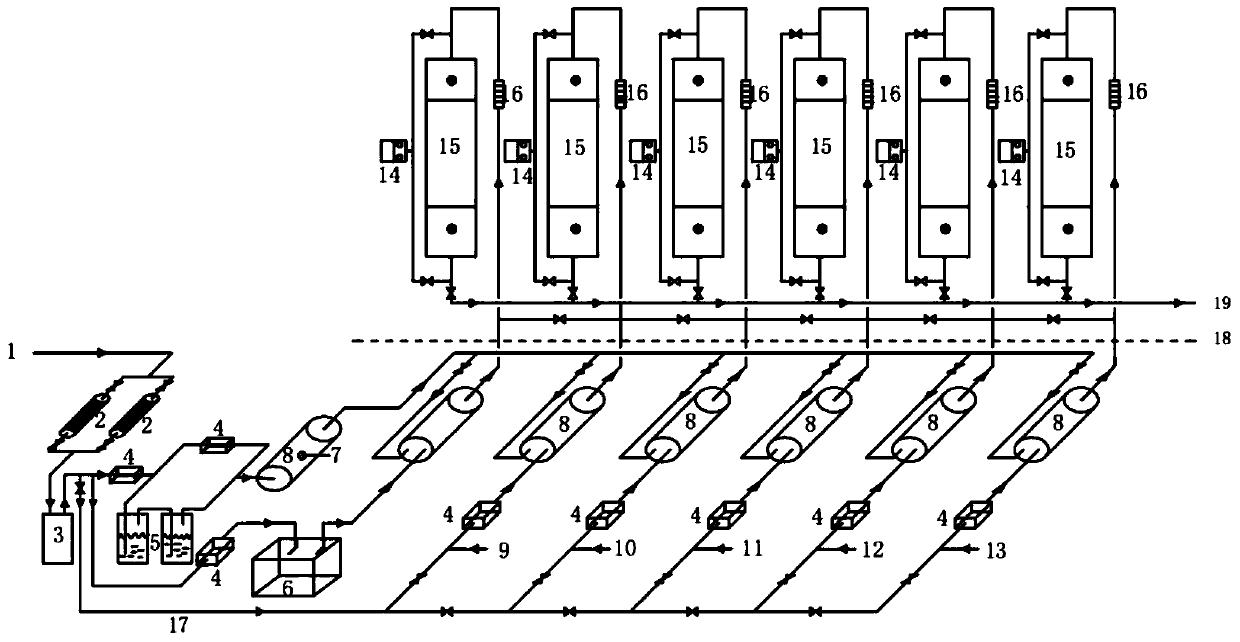

[0026] figure 1 It is the principle diagram of the system of the present invention, the performance test platform of various gaseous pollutant purification materials of the present invention, a stable loading air source is provided by an air compressor, and the compressed air 1 of the air source is dehumidified by the silica gel desiccant in the drying pipe 2, and the precision air is filtered The device 3 removes particles in the air, activated carbon removes organic matter and acid-base gases in the air, and finally realizes the drying and cleaning of the loaded air source. The air flow is partially bypassed through the two-stage humidification 5, and the humidity is control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap