Water conservancy project drainage pipe convenient to quickly combine and install

A combined installation and water conservancy engineering technology, applied in the sewer system, cleaning sewer, waterway system, etc., can solve the problems of difficult to meet the needs of water conservancy project construction, heavy workload, low connection efficiency, etc., to improve the installation speed and shorten the The effect of engineering construction period and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

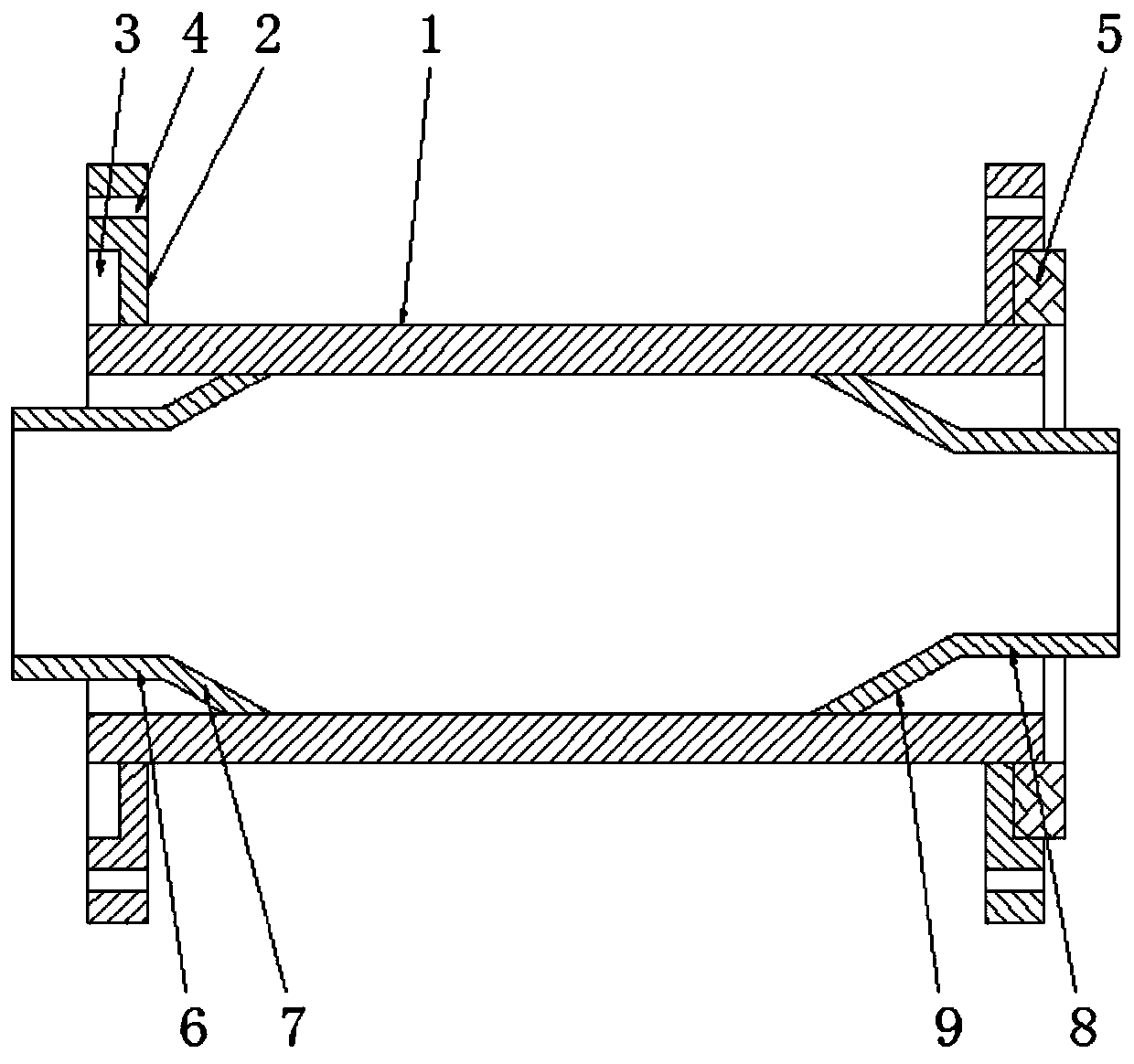

[0024] See figure 1 , a drainage pipe for water conservancy projects that is convenient for rapid assembly and installation, including a pipe body 1, the pipe body 1 is a circular pipe structure, and the left and right side ends of the pipe body 1 are symmetrically sleeved with connecting flanges 2, the connection method The outer end of the blue plate 2 is provided with a waterproof groove 3, the waterproof groove 3 is an annular structure, a sealing ring 5 is installed in the waterproof groove 3, the sealing ring 5 is made of rubber material, and the connecting flange 2 is evenly provided with several threaded holes 4, and the fast installation can be realized through the mutual cooperation between the connecting flanges 2 between the pipe bodies 1, so that the installation speed between the pipe bodies 1 is greatly improved, which is conducive to shortening the construction period. Improve work efficiency; and by placing a sealing ring 5 in the waterproof groove 3 between two

Embodiment 2

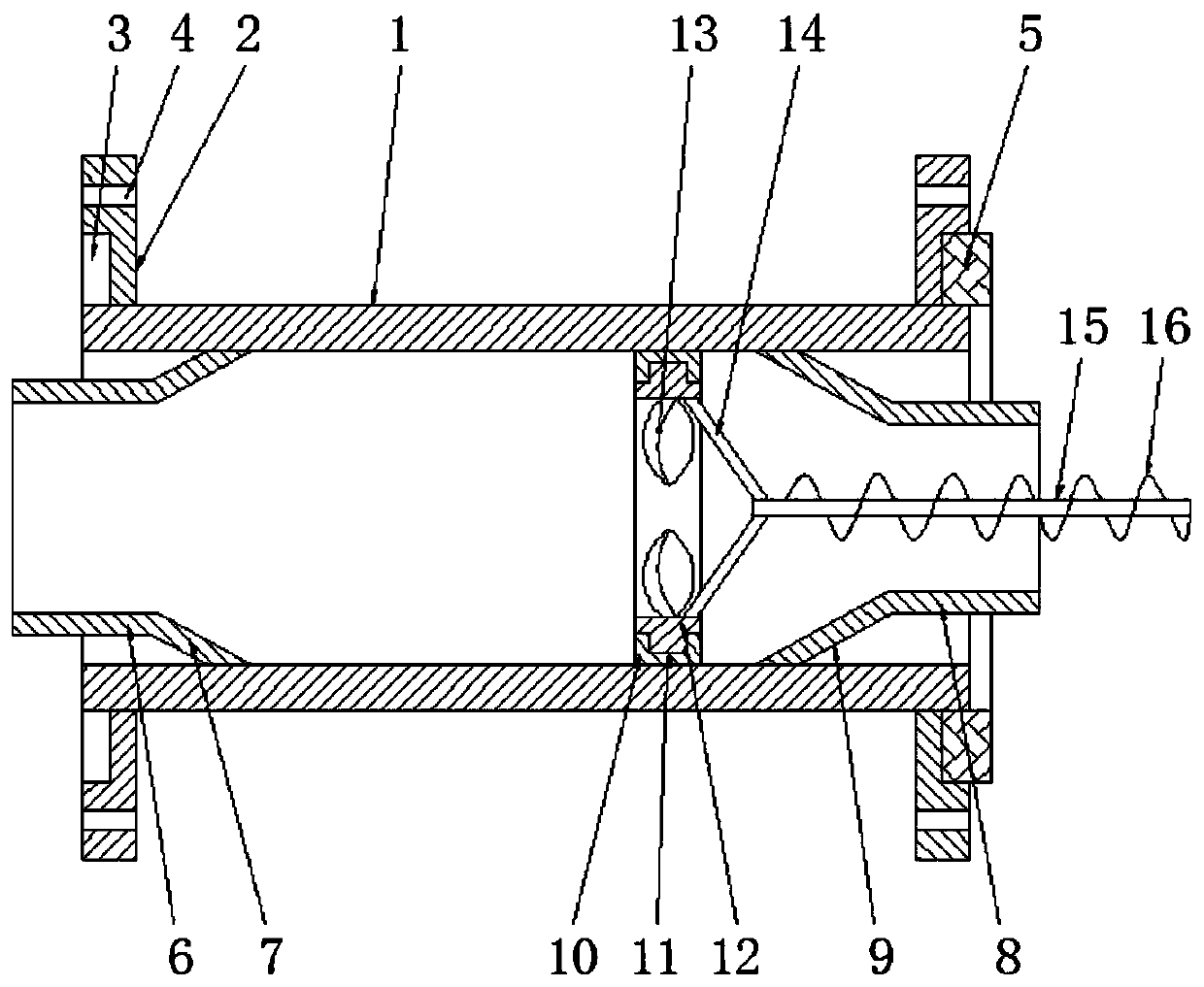

[0027] See figure 2, and the difference from Embodiment 1 is that: the inner cavity of the pipeline body 1 is provided with a slide rail 10 on the side close to the second inner connecting pipe 8, and the slide rail 10 is a ring structure, and the inside of the slide rail 10 The cavity is provided with a chute 11, and a swivel 12 is slidably connected in the chute 11. The swivel 12 is a circular ring structure, and the inner cavity of the swivel 12 is uniformly provided with several paddles 13. The second inner The inner cavity of the connecting pipe 8 is provided with a dredging rod 15 matched with the first inner connecting pipe 6, the axis of the dredging rod 15 coincides with the axis of the swivel 12, and the dredging rod 15 is fixedly connected to the swivel 12 through the connecting rod 14 , the dredging rod 15 is covered with a dredging auger 16, the dredging auger 16 is a space spiral structure, the water flow flows through the pipe body 1, the water flow impacts the pa

Embodiment 3

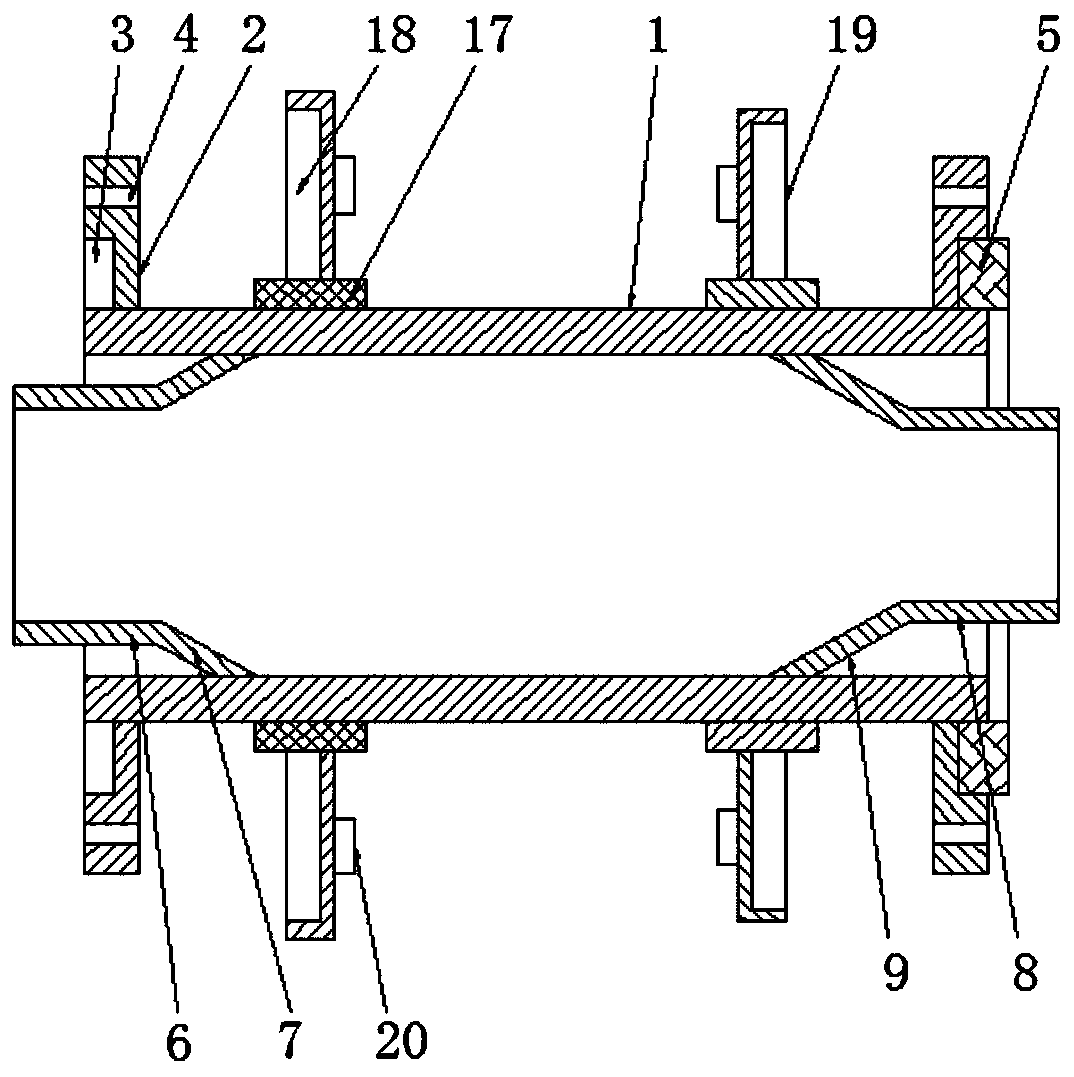

[0029] See image 3 The difference from Embodiment 1 is that: the left and right sides of the outer circular surface of the pipe body 1 are symmetrically sleeved with moving cylinders 17, and the moving cylinders 17 and the pipeline body 1 are rotationally connected, and one of the moving cylinders 17 is provided with a first outer sleeve 18, and the outer circumference of the other moving cylinder 17 is provided with a second outer sleeve 19 that matches the first outer sleeve 18, and the second outer sleeve 19 The inner cavity of the threaded inner sleeve 18 is used to seal the two outer sleeves 18 by utilizing the mutual cooperation between the second outer sleeve 19 on one pipeline body 1 and the first outer sleeve 18 on the other pipeline body 1. The two connecting flanges 2 connected between the pipe body 1 can not only further seal the connection gap between two adjacent connecting flanges 2, but also effectively prevent the external environment from affecting the connecti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap