A power winding structure

A winding structure and electric power technology, which is applied in the field of electric power, can solve problems such as inconvenient maintenance, unadjustable position, and potential safety hazards, and achieve the effects of high installation stability, improved stability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

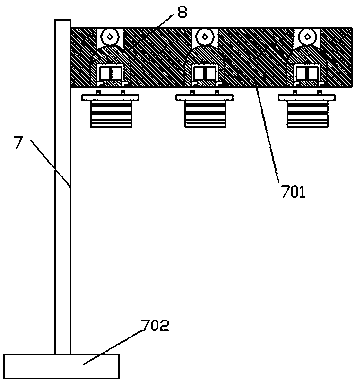

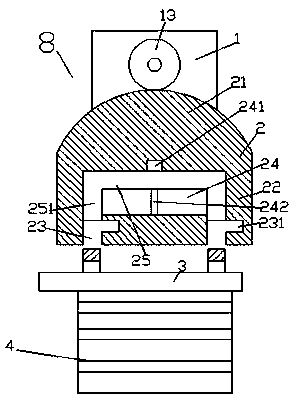

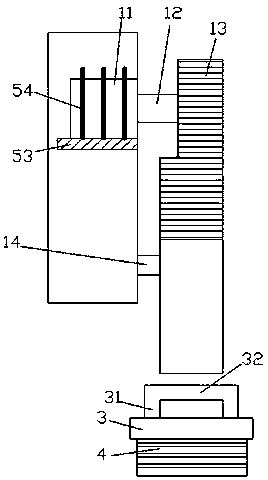

[0021] Such as Figure 1-Figure 6 As shown, an electric power winding structure of the present invention includes a utility pole 7 and a wire winder 8. The bottom of the utility pole 7 is fixed with a base 702, and the upper right end of the utility pole 7 is provided with a straight portion 701. The front end surface of the straight portion 701 is evenly provided with two or more sets of winders 8, the winders 8 including a straight plate 1, an operating part 2 connected with the straight plate 1 in a rotationally fitting manner, and a matching part connected with the operating part 2 The winding part 3 of the straight board 1 is fixedly connected to the front end face of the straight portion 701, the upper end of the front end face of the straight board 1 is provided with a regulating motor 11, and the lower end of the front end face of the straight board 1 is provided There is a bearing 14, a rotating shaft 12 is rotatably connected to the regulating motor 11, a toothed wheel 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap