A kind of synthetic method of γ-phase indium selenide

A synthesis method and technology of indium selenide, applied in the direction of binary selenium/tellurium compound, metal selenide/telluride, etc., can solve the problems of temperature rise, elemental selenium volatilization, etc., and achieve simple equipment, ensure uniformity, and easy scale The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of synthetic method embodiment of gamma phase indium selenide of the present invention, this synthetic method comprises the following steps:

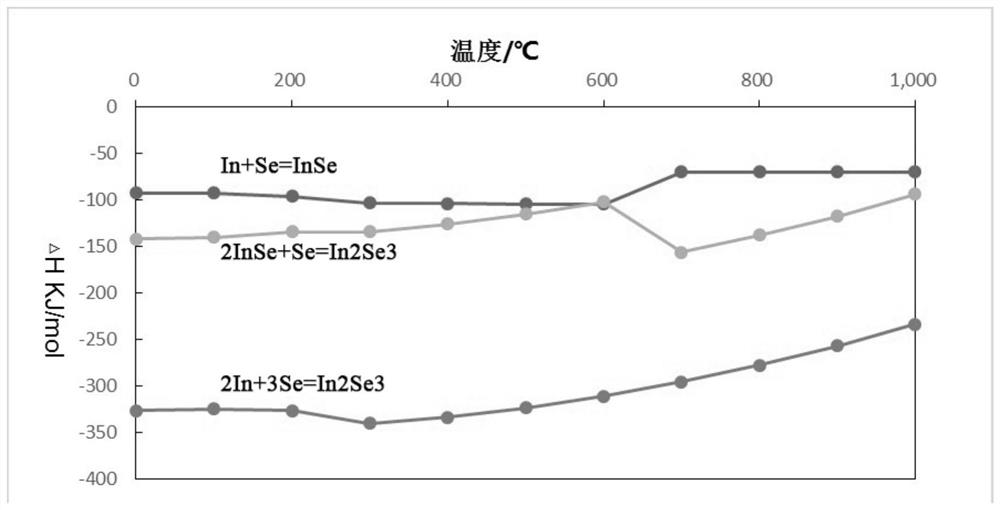

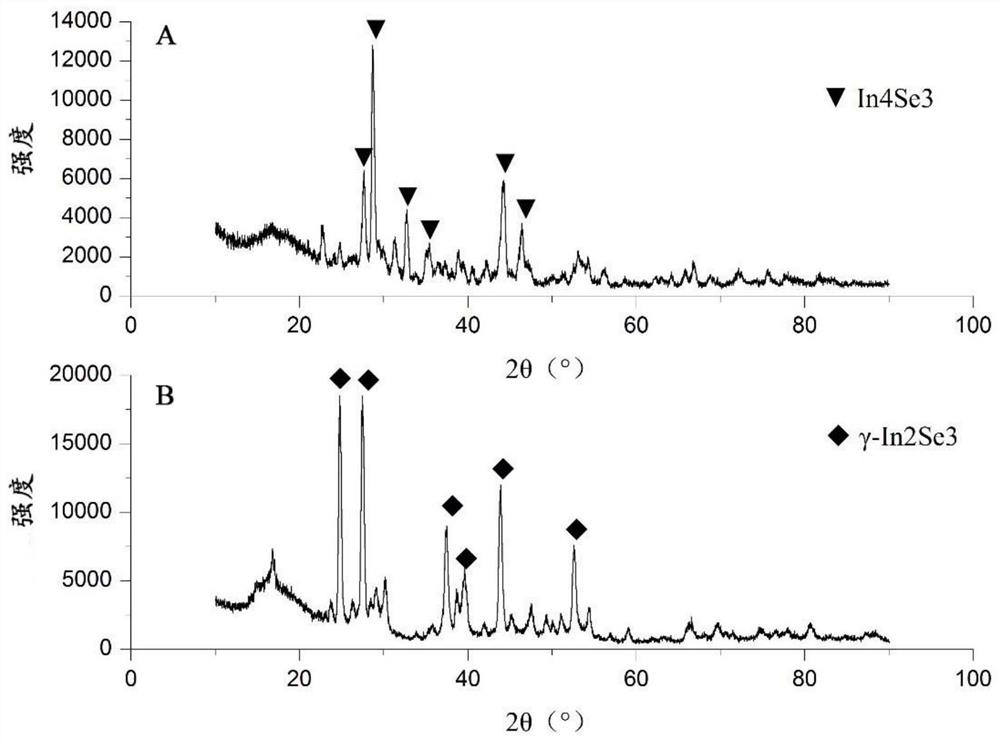

[0037] (1) According to the atomic ratio of selenium:indium=3:4, take by weighing 1531.35g of selenium particles (10-30mm) with a purity of 4.5N and 2968.65g of indium bars (1kg / root) with a purity of 4.5N, and put them into a quartz crucible Then put it into the normal pressure tubular synthesis furnace, and then replace the air in the furnace with nitrogen or argon at a flow rate of 6L / min for 1h, then raise the temperature to 190°C at a rate of 4°C / min, and then react at a constant temperature 4h, make elemental selenium and elemental indium react at low temperature, prevent the reaction temperature from being too high to cause the volatilization loss of elemental selenium, and feed in nitrogen or argon with a flow rate of 3L / min while heating; after the constant temperature reaction, adjust the flow rate to 10L / m

Embodiment 2

[0041] A kind of synthetic method embodiment of gamma phase indium selenide of the present invention, this synthetic method comprises the following steps:

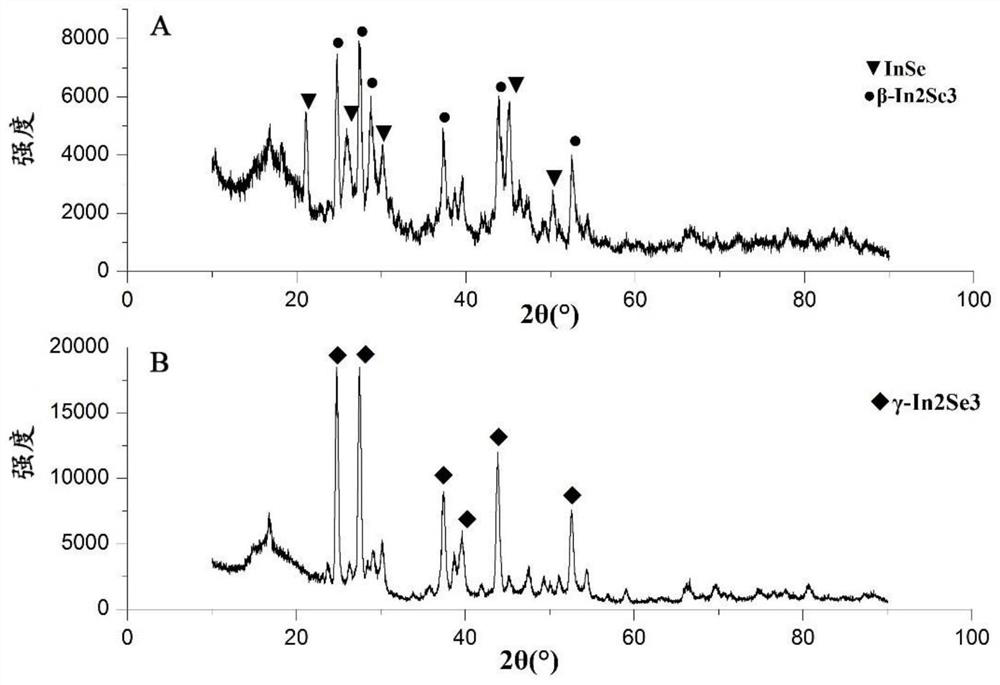

[0042] (1) According to the atomic ratio of selenium: indium=1:1, take by weighing 1833.75g of selenium grains (10-30mm) with a purity of 4.5N and 2666.25g of indium strips (1kg / root) with a purity of 4.5N, and put them into a graphite crucible Then put it into the normal pressure tubular synthesis furnace, and then replace the air in the furnace with nitrogen or argon at a flow rate of 5L / min for 1h, then raise the temperature to 210°C at a rate of 4°C / min, and then react at a constant temperature 4h, make elemental selenium and elemental indium react at low temperature, prevent the reaction temperature from being too high and cause the volatilization loss of elemental selenium, feed in nitrogen or argon with a flow rate of 4L / min while heating; Min hydrogen volume content is 7% nitrogen or argon, while continuing to

Embodiment 3

[0046] A kind of synthetic method embodiment of gamma phase indium selenide of the present invention, this synthetic method comprises the following steps:

[0047] (1) Take by weighing the selenium particle (10-30mm) 2003.38g that purity is 4.5N and the indium bar (1kg / piece) 2486.62g that purity is 4.5N by the atomic ratio of selenium:indium=7:6, put into graphite crucible Then put it into the atmospheric pressure tubular synthesis furnace, and then pass in nitrogen or argon at a flow rate of 10L / min for 1.5h to replace the air in the furnace, and then raise the temperature to 230°C at a heating rate of 5°C / min, and then keep the temperature constant React for 5 hours to react elemental selenium and elemental indium at a low temperature to prevent the volatilization loss of elemental selenium caused by too high a reaction temperature. While heating, feed nitrogen or argon with a flow rate of 5L / min; after the constant temperature reaction is completed, adjust the flow ra

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap