Servo system rotation clearance simulation device

A simulation device and servo system technology, applied in rigid shaft couplings, mechanical equipment, couplings, etc., can solve the problems of requirements, experimental data not accurate and comprehensive, and high experimental conditions, and achieve low cost, simple structure, and abundant Effect of Experimental Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

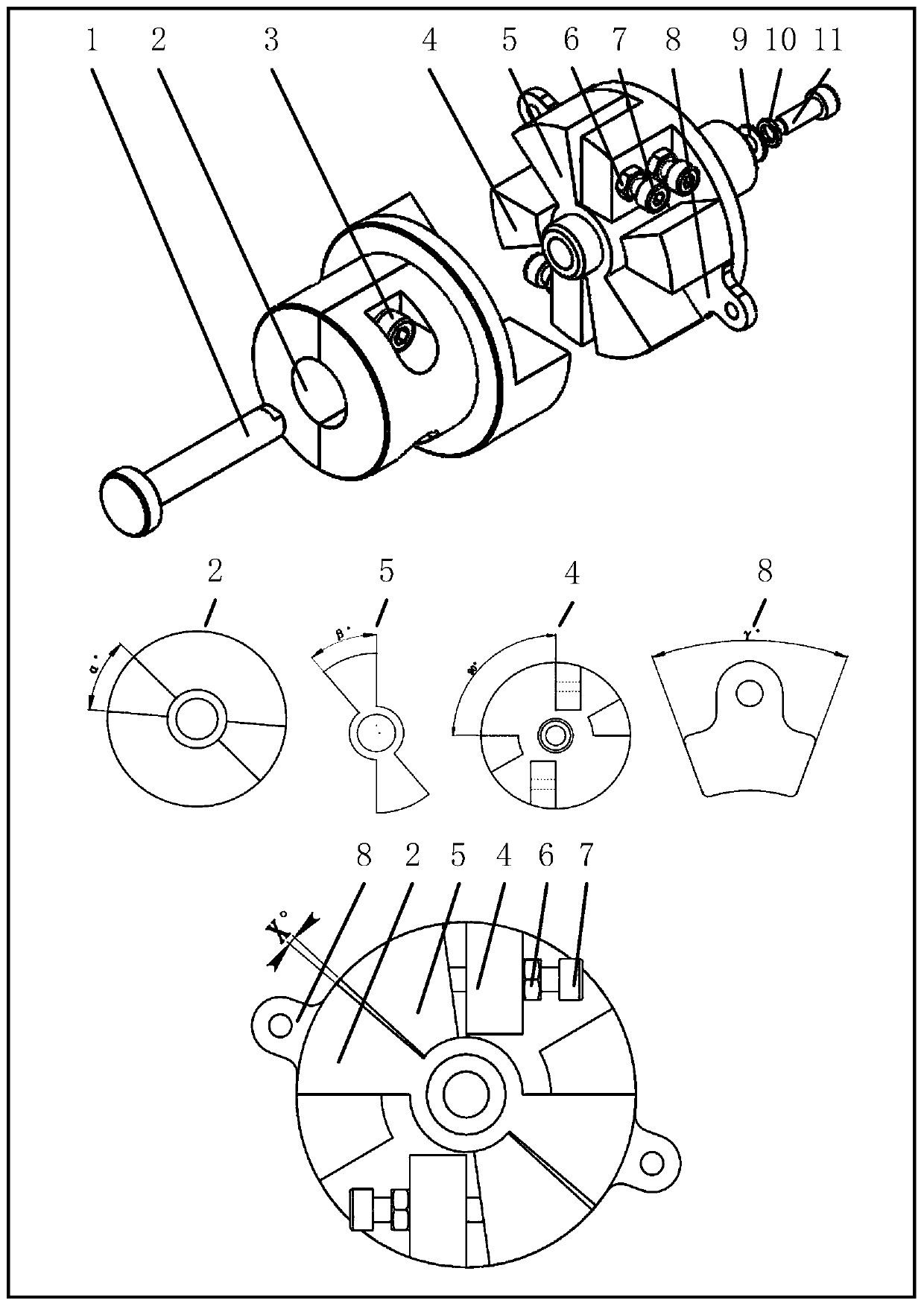

[0029] The invention relates to a servo system rotation gap simulation device, which is a simulation device specially used for studying the nonlinear effect of the servo system rotation gap. See figure 1 As shown, it includes coaxial fixed rod 1, roulette coupling 2, coupling fastening screw 3, fixed-angle roulette 4, rotary slider 5, lock nut 6, adjusting screw 7, fixed-angle plug Ruler 8, coaxial spacer 9, spring spacer 10 and fastening screw 11; Their mutual positional relationship is: wheel coupling 2, rotary slider 5 and fixed-angle wheel 4 are arranged in order, and the rotation The slider 5 is in the middle; the coaxial fixed rod 1 passes through the round hole in the middle of the wheel coupling 2 and the fixed-angle wheel 4, and is connected with the coaxial spacer 9, the spring spacer 10 and the fastening screw 11 through threads Fix together; the co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap