Oil spilling repair agent, preparation method thereof, and oil spilling in-situ repair method

A restoration agent and oil spill technology, applied in separation methods, chemical instruments and methods, fixed on/in organic carriers, etc., can solve problems such as immobilized particles that do not mention floating microbe-degrading bacteria on the water surface, etc., achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) Weigh 1000g of agar, add 50L of water, heat it to 90°C, then pass in 120°C of water vapor for heat melting, add 50L of normal temperature water and stir to adjust the temperature to 65°C, the concentration of agar at this time is 10g / L, and then add 1g of surfactant sodium lauryl sulfate, the concentration of which in the solution is 0.01g / L, stir at a speed of 10rpm for about 1h to make it evenly mixed, and keep the aqueous solution at 65°C for heat preservation.

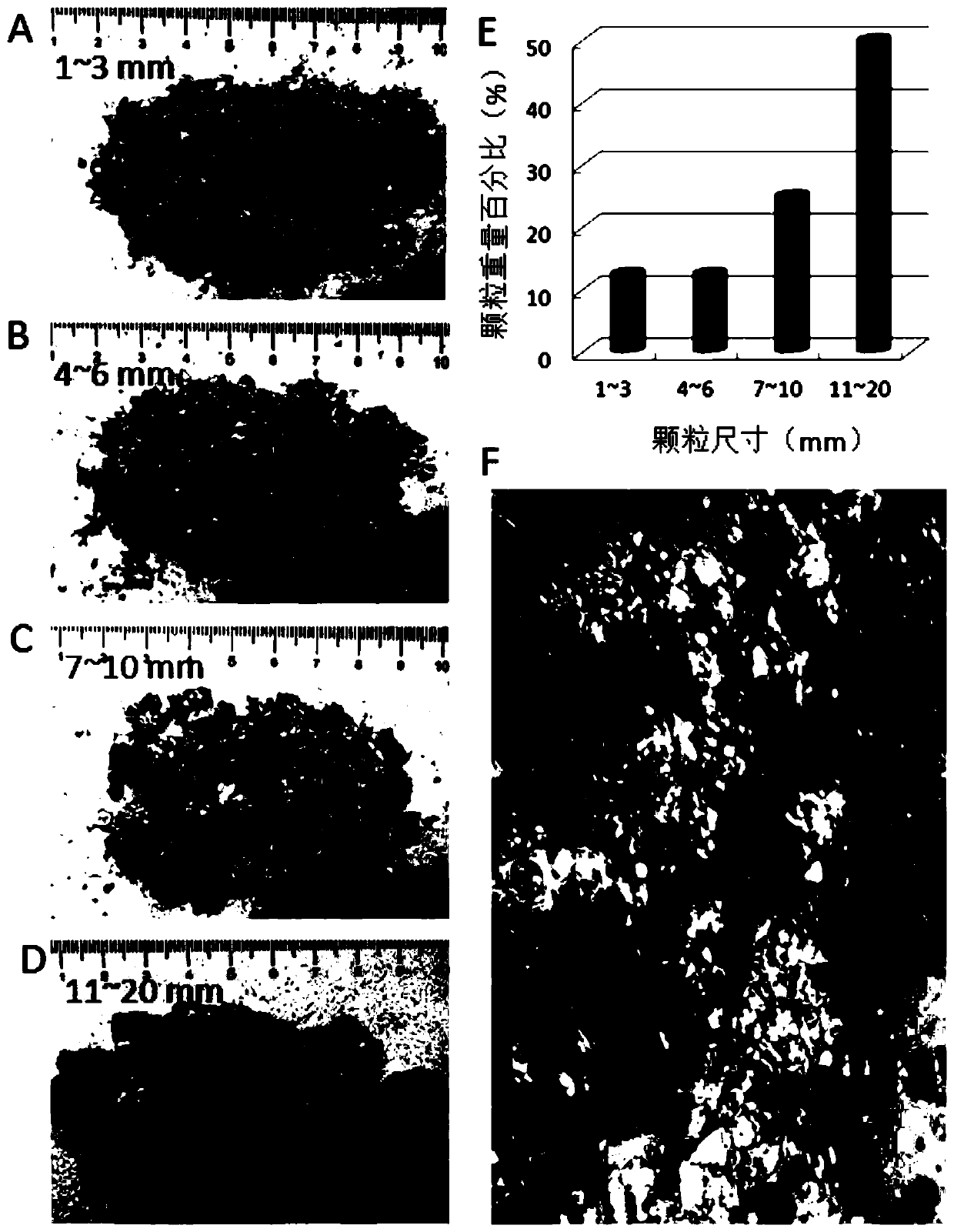

[0039] (2) Use corn cob as the wood fiber carrier, crush and sieve with a pulverizer, adjust the size of the sieve, and take crushed particles with a size of 1 to 3mm, 4 to 6mm, 7 to 10mm, and 11 to 20mm in a ratio of 1:1: Mix 2:4, the total weight is 5KG, disperse the commercially available or self-made microbial agent with water to prepare 5KG of microbial agent suspension, pour the agent suspension evenly on the corncob particles, and roll and stir to complete Mix well, turn the particles over every

Embodiment 2

[0042] (1) Weigh 2000g of agar, add 50L of water, heat to 90°C and then pass through 120°C water vapor for thermal melting, add 50L of normal temperature water and stir to adjust the temperature to 35°C, the concentration of agar at this time is 20g / L, then add 200g soap powder as a surfactant, the concentration in the solution is 2g / L, stir at a speed of 50rpm for about 1h to make it evenly mixed, and keep the aqueous solution at 35°C for heat preservation.

[0043] (2) Use corn stalks, corn cobs, and sorghum stalks as wood fiber carriers, grind and sieve with a pulverizer, adjust the sieve size, take 10KG of crushed particles with a size of 5-20 mm, and mix commercially available or self-made microbial bacteria Disperse the agent with water to make 50KG of microbial agent suspension, pour the agent suspension evenly on the pulverized particles, and roll and stir to mix evenly, and the mixing time of the two is 10min.

[0044] (3) Wrap the pretreated particles with a total

Embodiment 3

[0046] (1) Weigh 3000g of agar, add 50L of water, heat it to 90°C, then pass in 120°C of water vapor for thermal melting, add 50L of normal temperature water and stir to adjust the temperature to 45°C, the concentration of agar at this time is 30g / L, then add 50g each of Tween-80 and octylphenol polyoxyethylene ether-100 as surfactants, the total concentration in the solution is 1g / L, stir at a speed of 20rpm for about 1h to make it evenly mixed, this aqueous solution is at 45 ℃ insulation.

[0047] (2) Use wheat straw and cotton straw as the wood fiber carrier, crush and sieve with a pulverizer, adjust the size of the sieve, take 20KG of crushed particles with a size of 2-10mm, and disperse the commercially available or self-made microbial agent with water. Prepare 80KG of microbial bacterial agent suspension, pour the bacterial agent suspension evenly on the pulverized particles, and roll and stir to mix evenly, and the mixing time of the two is 24 hours.

[0048] (3) Wra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap