Method for producing fuel ethanol by fermentation of green alga biomass

A technology of biomass fermentation and fuel ethanol, applied in the direction of biofuel and fermentation, can solve problems such as aggravating the social food crisis, and achieve the effects of low cost, no secondary pollution, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for producing fuel ethanol by fermenting green algae biomass is as follows:

[0027] (1) Preparation of Chlorella Hydrolyzed Sugar Solution:

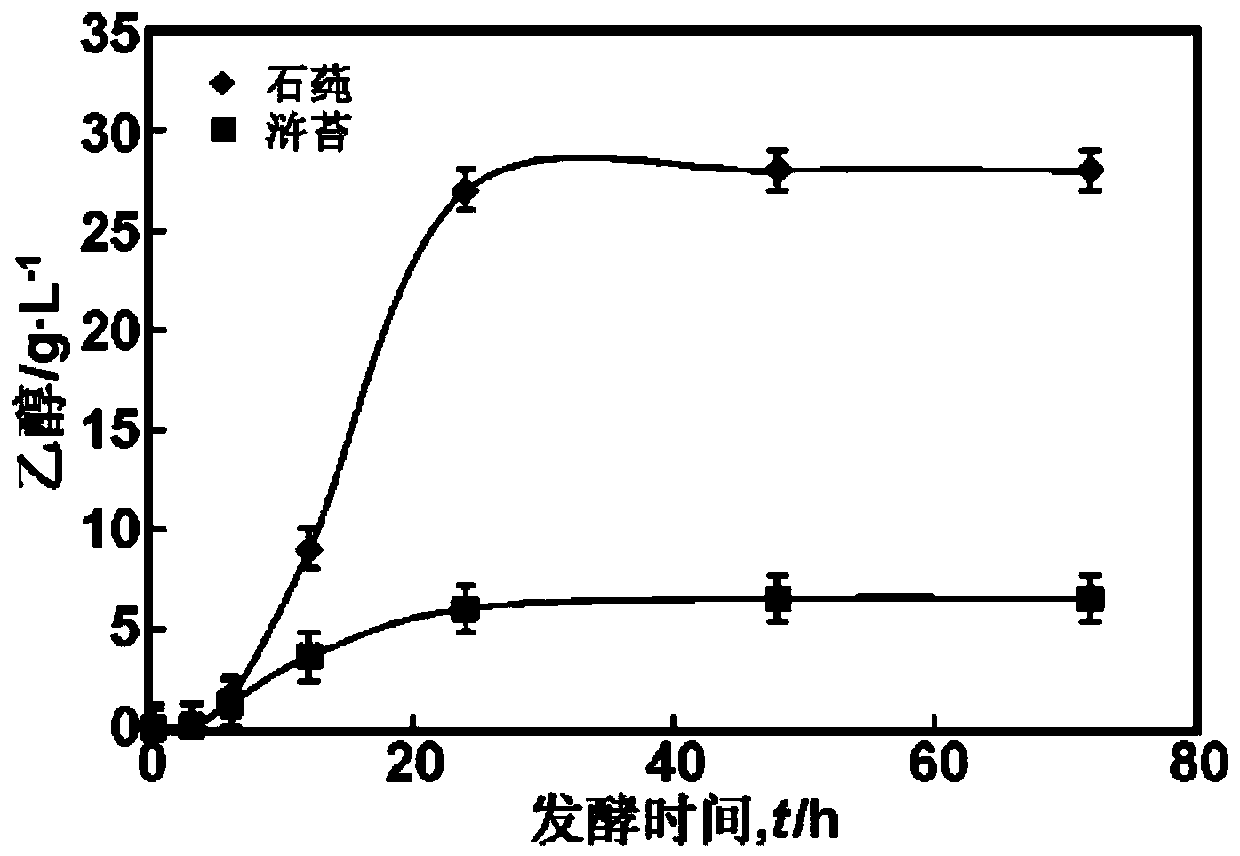

[0028] Step 1: after crushing Ulva and Enteromorpha respectively, weigh a certain amount of green algae powder to make 350g / L raw material.

[0029] Step 2: Add liquefaction enzyme (80IU / g) and glucoamylase (40IU / g) to the raw material in step 1 in sequence, the liquefaction enzyme treatment condition is 60°C, pH value is 6, the glucoamylase treatment condition is 60°C, pH value Under the condition of 4.5, they were hydrolyzed for 48 and 36 hours respectively.

[0030] Step 3: acid hydrolyze the raw material after enzymatic hydrolysis with 2% sulfuric acid, treat at 120°C for 2h, centrifuge at 3000r for 10min, and collect the supernatant.

[0031] Step 4: Adjust the pH of the hydrolyzed sugar solution to 5.5 with calcium hydroxide. Sterilize at 106°C for 30 minutes before use.

[0032] Step 5: Do three parallel fe

Embodiment 2

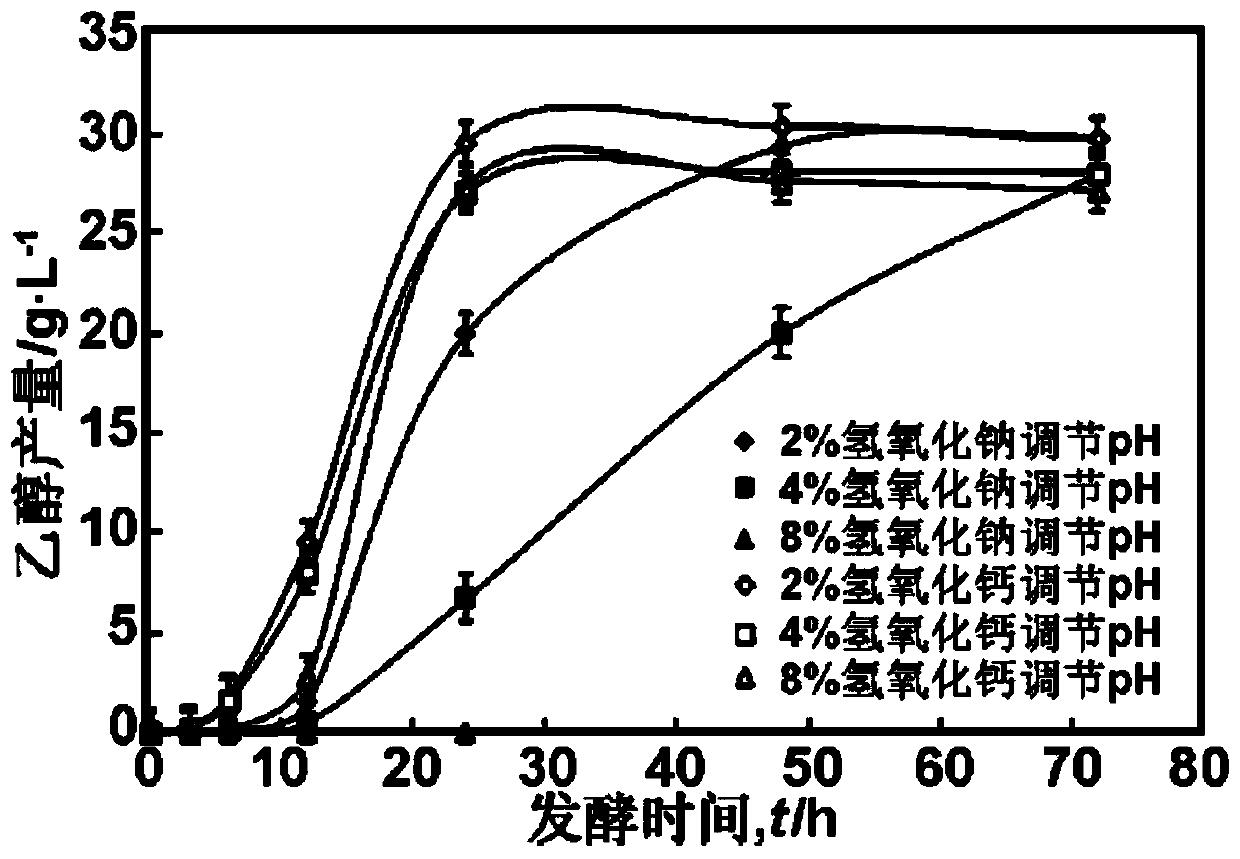

[0038] A method for producing fuel ethanol by fermenting green algae biomass is as follows:

[0039] (1) Preparation of Chlorella Hydrolyzed Sugar Solution:

[0040] Step 1: after crushing Ulva and Enteromorpha respectively, weigh a certain amount of green algae powder to make 350g / L raw material.

[0041] Step 2: Add liquefaction enzyme (80IU / g) and glucoamylase (40IU / g) to the raw material in step 1 in sequence, the liquefaction enzyme treatment condition is 60°C, pH value is 6, the glucoamylase treatment condition is 60°C, pH value Under the condition of 4.5, they were hydrolyzed for 48 and 36 hours respectively.

[0042] Step 3: acid hydrolyze the raw material after enzymolysis with 4% sulfuric acid, treat at 120°C for 2h, centrifuge at 3000r for 10min, and collect the supernatant.

[0043] Step 4: Adjust the pH of the hydrolyzed sugar solution to 5.5 with calcium hydroxide. Sterilize at 106°C for 30 minutes before use.

[0044] Step 5: Do three parallel fermentatio

Embodiment 3

[0050] A method for producing fuel ethanol by fermenting green algae biomass is as follows:

[0051] (1) Preparation of Chlorella Hydrolyzed Sugar Solution:

[0052] Step 1: after crushing Ulva and Enteromorpha respectively, weigh a certain amount of green algae powder to make 350g / L raw material.

[0053] Step 2: Add liquefaction enzyme (80IU / g) and glucoamylase (40IU / g) to the raw material in step 1 in sequence, the liquefaction enzyme treatment condition is 60°C, pH value is 6, the glucoamylase treatment condition is 60°C, pH value Under the condition of 4.5, they were hydrolyzed for 48 and 36 hours respectively.

[0054] Step 3: acid hydrolyze the raw material after enzymolysis with 8% sulfuric acid, treat at 120° C. for 2 hours, centrifuge at 3000 r for 10 minutes, and collect the supernatant.

[0055] Step 4: Adjust the pH of the hydrolyzed sugar solution to 5.5 with calcium hydroxide. Sterilize at 106°C for 30 minutes before use.

[0056] Step 5: Do three paralle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap