A method for reversibly modifying carbon fibers

A technology for carbon fiber and surface modification, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of carbon fiber surface structure damage, traditional surface modifiers cannot be reversibly recycled, and achieve the effect of reducing material costs and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for reversibly modifying carbon fibers, comprising the steps of:

[0030] Step 1. Pretreatment of carbon fiber: desizing carbon fiber tow (PAN carbon fiber, HTS40) under nitrogen protection at 500°C to obtain desizing carbon fiber;

[0031] Step 2. Prepare a ferrocene derivative solution: add ferrocene formic acid (Aladdin) into deionized water according to the proportion and evenly disperse and dissolve it to obtain a ferrocene derivative solution with a concentration of 1.0 mM;

[0032] Step 3. Surface modification of carbon fibers: Take 1 g of the continuous carbon fiber tow desized in step 1 and add it to 100 ml of the ferrocene derivative solution prepared in step 2, shake it in a constant temperature oscillator at 15°C for 200 min, and use centrifugation Separation, the separation time is 5min, the supernatant is removed, and the carbon fiber modified by the ferrocene derivative is dried under normal pressure for 1h, and the drying temperature is 10°C, that

Embodiment 2

[0035] A method for reversibly modifying carbon fibers, comprising the steps of:

[0036] Step 1. Pretreatment of carbon fiber: desizing carbon fiber tow (PAN carbon fiber, HTS40) at 500°C in air to obtain desized carbon fiber;

[0037]Step 2. Preparation of ferrocene derivative solution: (ferrocenemethyl) dodecyl dimethyl ammonium bromide (Tokyo Chemical Industry Co., Ltd., Japan) is added into deionized water according to the proportion and evenly dispersed and dissolved to obtain A ferrocene derivative solution with a concentration of 10 mM;

[0038] Step 3. Surface modification of carbon fiber: take 0.01g of the chopped carbon fiber desized in step 1 and add it to 100ml of the ferrocene derivative solution prepared in step 2, let it stand in a constant temperature water bath at 50°C for 1min, and filter it Separation, the separation time is 100min, the supernatant is removed, and the carbon fiber modified by the ferrocene derivative is vacuum-dried for 48h, and the drying te

Embodiment 3-6

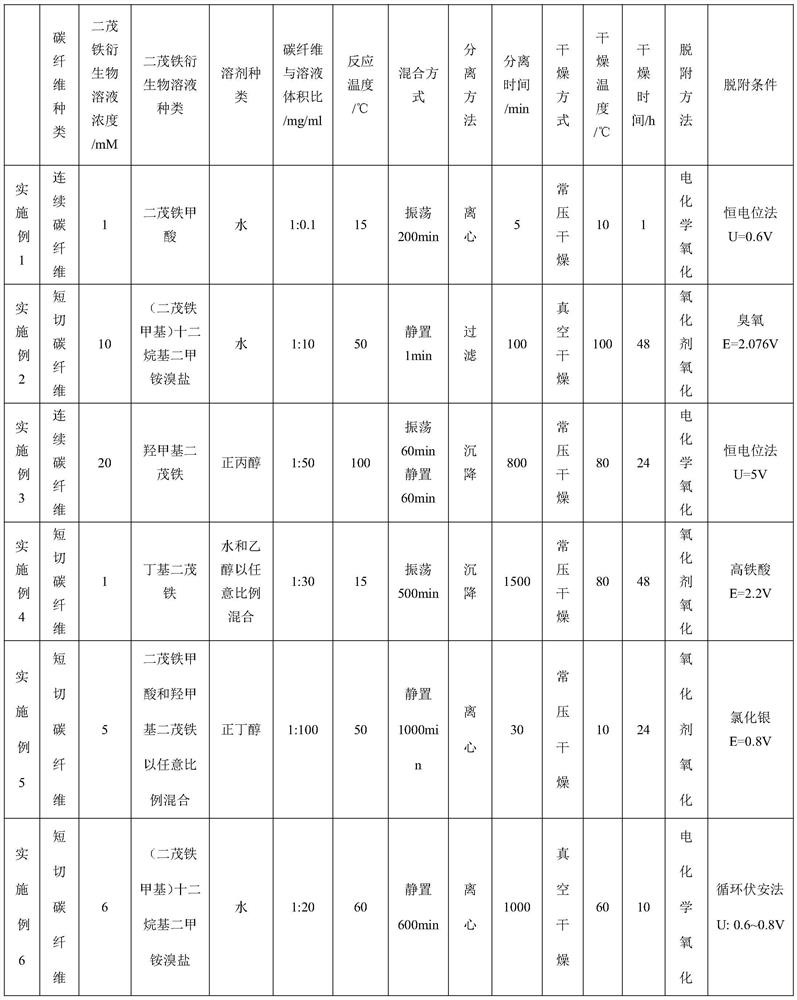

[0041] Embodiment 3-6 basic operation steps are the same as embodiment 1 and embodiment 2, change carbon fiber type, ferrocene derivative type and solution concentration, carbon fiber mass and solution volume ratio, reaction temperature, mixing mode, separation method, separation time, One or several items in the drying method, temperature, time, desorption method and desorption conditions, the specific conditions corresponding to each embodiment are listed in Table 1.

[0042] In addition to examples 1-6 listed, the solvent in the ferrocene derivative solution can also be replaced with acetone or tetrahydrofuran; the oxidizing agent in the oxidation of the oxidizing agent can also be replaced with concentrated sulfuric acid, hypochlorous acid, oxygen, permanganic acid , bromine or iodic acid instead; the electrochemical oxidation can also adopt constant current method.

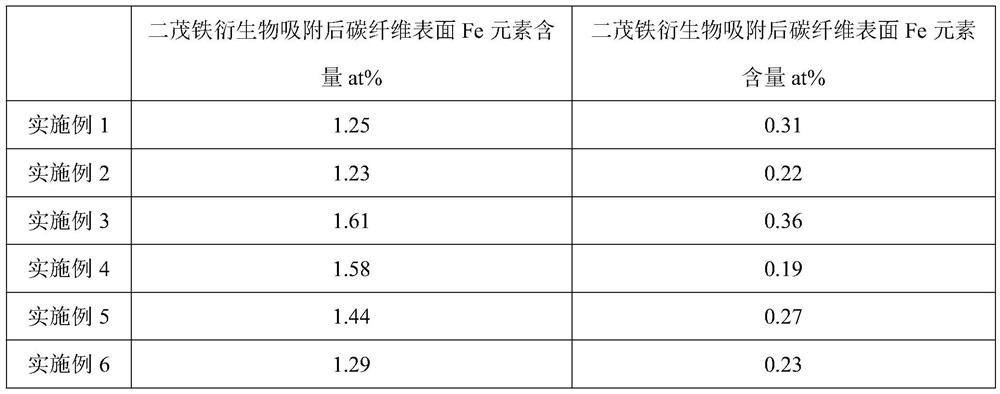

[0043] Through X-ray photoelectron spectroscopy analysis, the content of Fe element on the surface of carbon

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap