Vacuum gas replacement crushing and continuous packaging processing device for preventing food oxidation

A technology of gas replacement and treatment equipment, applied in the direction of packaging, transportation and packaging, packaging, etc. under vacuum/special atmosphere, to achieve the effect of preventing quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

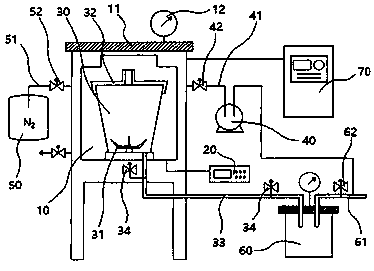

Method used

Image

Examples

Embodiment 1

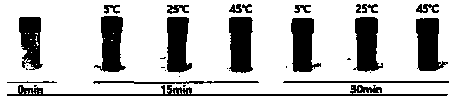

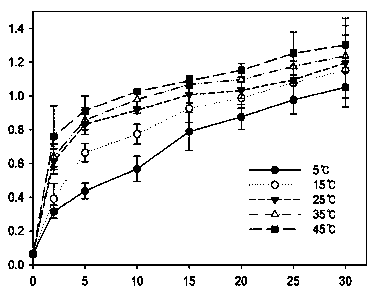

[0062] Example 1 Effect of Grinding Temperature on Total Phenolic Content, Antioxidant Activity and Browning of Applesauce

[0063] experimental method

[0064] 1. Put all the grinding tools, water and apples in the incubator at a specific temperature for 3 hours to set the temperature of all the tools, water and apples for grinding.

[0065] 2. Remove the apple peel from the incubator and divide into 8 pieces.

[0066] 3. Put 50g of apple slices into a blender, add 50g of water, grind for 30 seconds, and then store in the incubator.

[0067] 4. Samples were taken at 5-minute intervals for 30 minutes to determine total phenol content, antioxidant activity (DPPH radical scavenging activity) and browning.

[0068] [Experimental Results]

[0069] Such as Figure 2 to Figure 5 Shown, as total phenol content, antioxidant activity, browning degree of apple puree, grinding temperature faster browning phenomenon and total phenol content, antioxidant experimental results. Activity is

Embodiment 2

[0071] Example 2: Effect of heat treatment using an antioxidant reactor on total phenolic content, antioxidant activity and browning of apples

[0072] experimental method

[0073] 1. Use a vacuum gas displacement grinder to crush apples: water (1:1) under vacuum at 2.67kPa for 30 seconds.

[0074] 2. Apple: crush water (1:1) in general air (101.33kPa) for 30 seconds as general grinding.

[0075] 3. Immediately after the vacuum grinding, a 50 g oxidation reactor was placed in a vacuum state by applying a vacuum for 10 minutes, and then heat-treated at 80° C. for 30 minutes for vacuum heat treatment.

[0076] 4. Immediately after vacuum crushing, 50 g was put into a bottle and heat-treated at 80° C. for 30 minutes in normal air.

[0077] 5. Vacuum crushing, general crushing, vacuum heat treatment after vacuum crushing, general heat treatment after vacuum crushing Put the apple puree at room temperature (about 25°C) for 1 day, then the total phenol content, antioxidant activity (

Embodiment 3

[0078] The effect of embodiment 3 antioxidant reactor and vacuum packaging on the browning of applesauce

[0079] experimental method

[0080] 1. Use a vacuum gas displacement grinder to crush apples: water (1:1) under vacuum at 2.67kPa for 30 seconds.

[0081] 2. After vacuum breaking, put 50g into the oxidation reactor and apply vacuum again for 15 minutes.

[0082] 3. Then put them in conventional packaging or vacuum packaging, and leave them at room temperature (about 25°C) for 7 days, then observe and compare the browning.

[0083] Therefore, if applesauce is vacuum-packed after vacuuming, it is considered to be effective in preventing apples from browning.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap