Wind power blade lightning protection system mounting method

The technology of a lightning protection system and installation method, which is applied in the direction of assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problems of difficulty in meeting production needs, non-compliance, and long time consumption, and achieves improvement of installation efficiency and labor efficiency. High, reduced operator effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

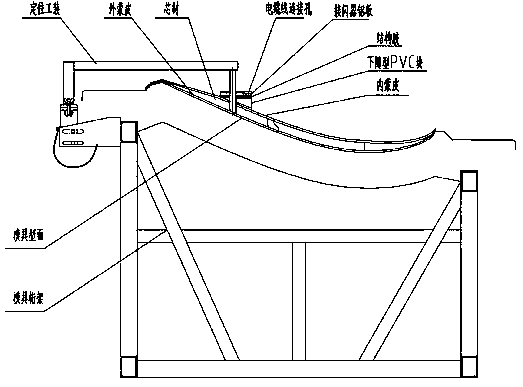

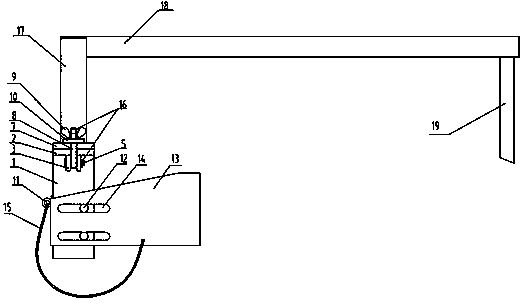

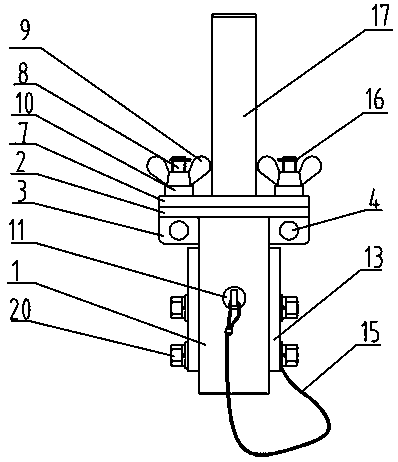

[0025] Example 1, see Figure 1-6 ,

[0026] A method for installing a lightning protection system for wind turbine blades, comprising the following steps:

[0027] (1) Process the mold according to the normal operation process, lay the release cloth, two layers of glass fiber outer skin cloth, lay the leaf root reinforcement layer, place the main beam, and lay the core material;

[0028] (2) After laying the core material, remove the small core material square with a size of 30mm*30mm at the specified position on the suction surface of the blade according to the design requirements, mark its upper and lower surfaces, and refill the small core material square into the In the 30mm*30mm square hole of the core material, it is used to mark the installation position of the aluminum plate of the lightning receptor. The spanwise error of the marked position is ±20mm, and the chord error is ±3mm;

[0029] (3) After the marking is completed, lay the glass fiber cloth of the leaf root r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap