Casing coupling reverse buckling device and using method thereof

A casing collar and undercut technology, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., can solve the problems that the operation cannot be carried out smoothly, the casing fishing device is stuck in the casing, etc., so as to avoid jamming and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] It should be noted that the following damaged casing refers to the uppermost casing in the downhole casing, and the upper end of the casing is provided with a casing collar, and the casing collar is located at the wellhead. In addition, the following “deformation” of the card body 2 means that the card body 2 is stretched outward.

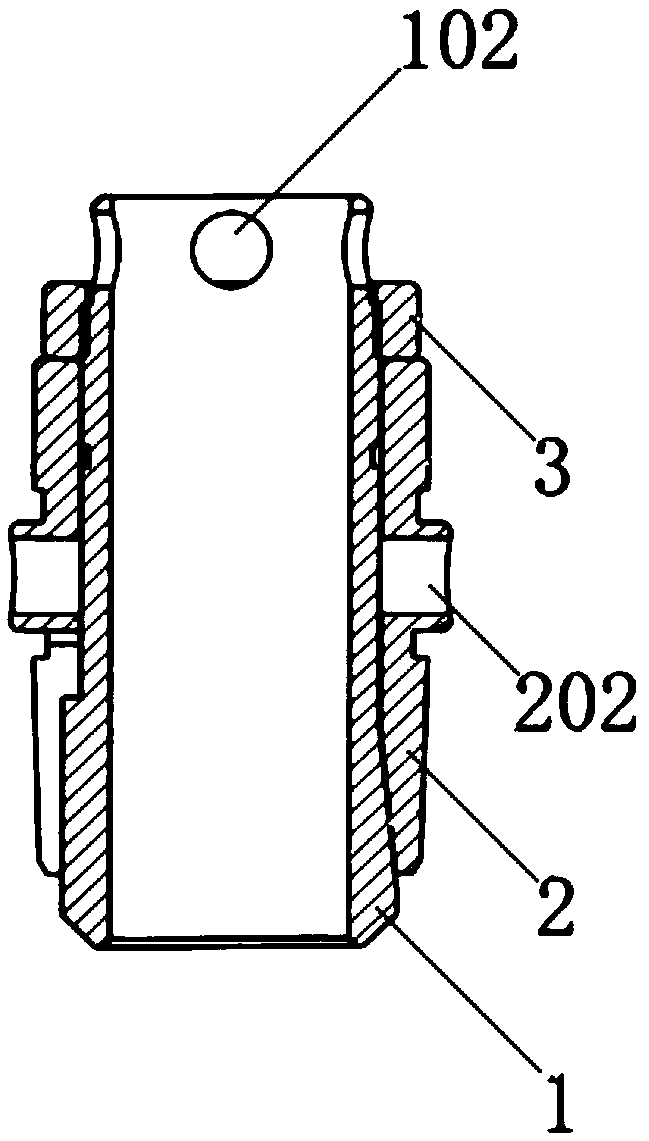

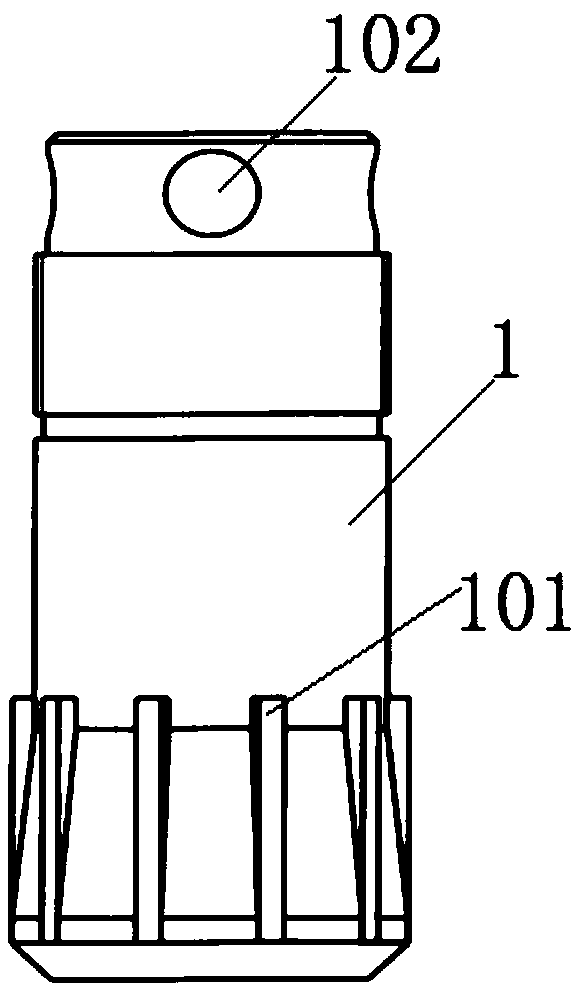

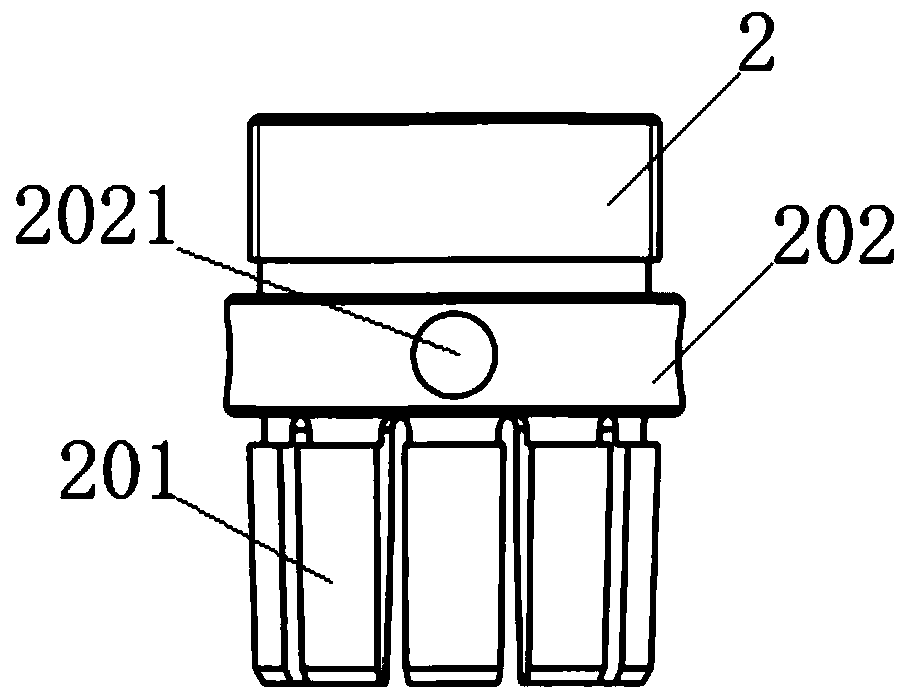

[0041] In the first aspect, the embodiment of the present invention provides a casing collar back-off device, such as the attached figure 1 , attached figure 2 , attached image 3 As shown, the device for undercutting the casing collar includes: a shaft body 1 , a card body 2 , and a locking member 3 . Wherein, the shaft body 1 is a tubular structure, and is sheathed in the card body 2 in an axially

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap