Operating table for tin bag wrapped samples with different diameters

An operating table and tin capsule technology, which is applied to the field of the operating table for wrapping tin capsule samples, can solve the problems affecting the efficiency of wrapping solid samples, easy side dumping, small tin capsule base, etc., and achieves low material price, easy material acquisition, and production. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

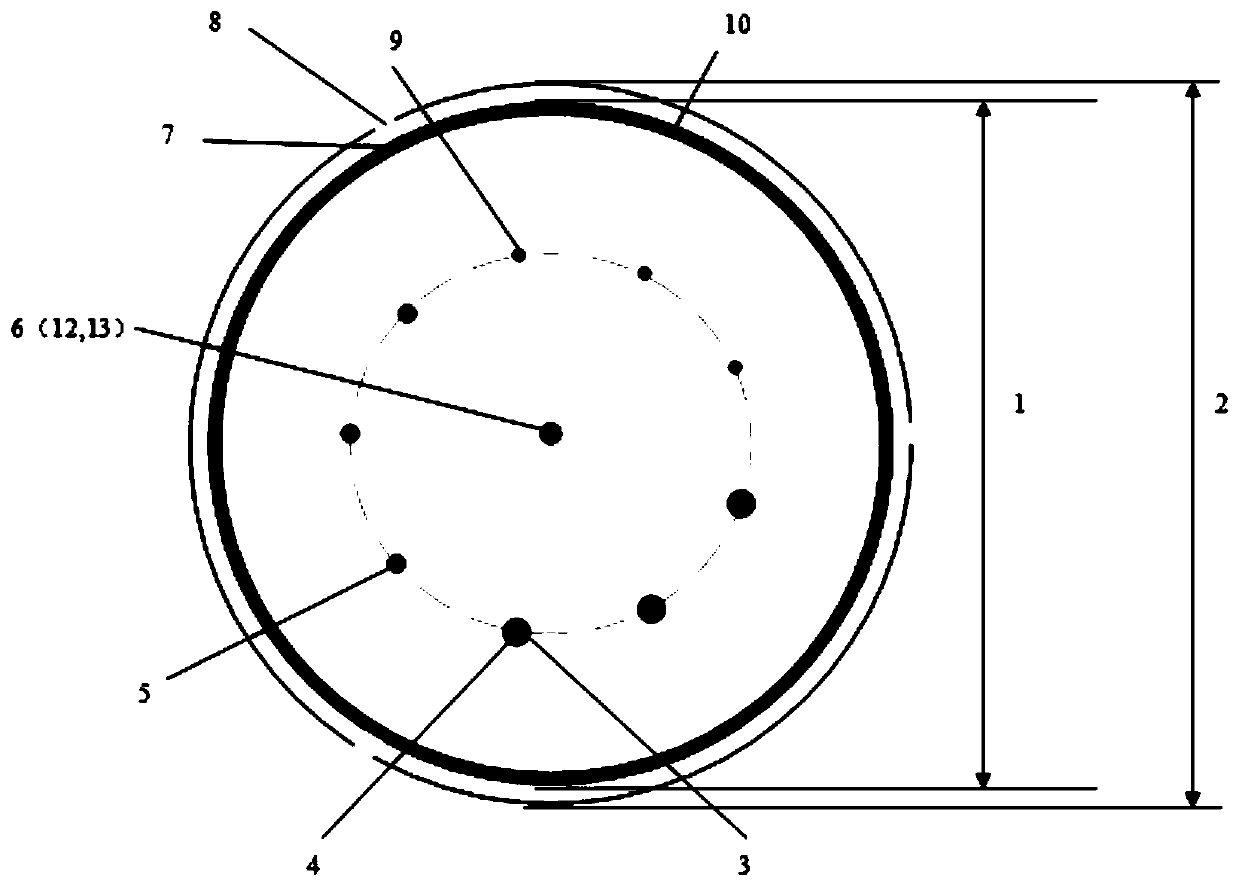

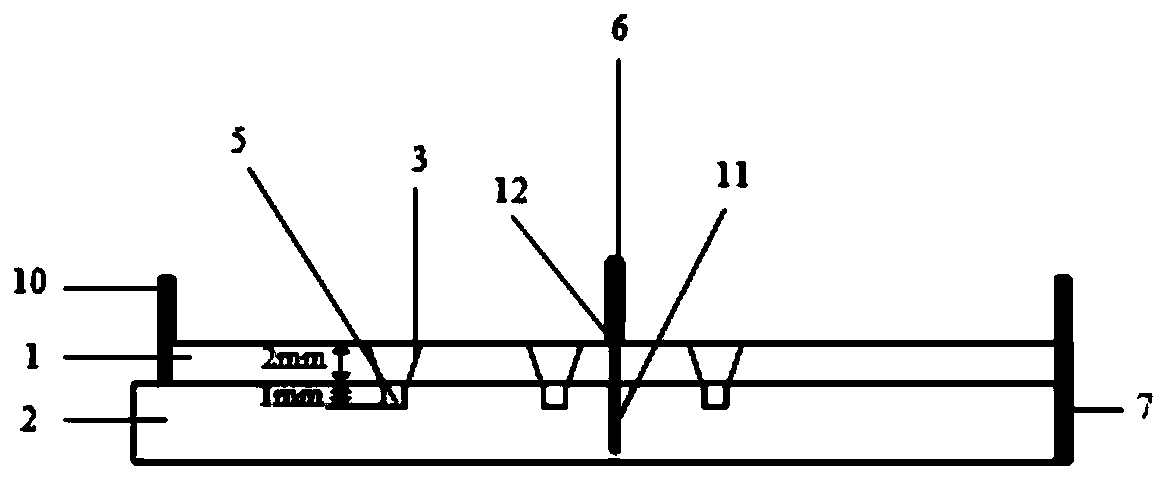

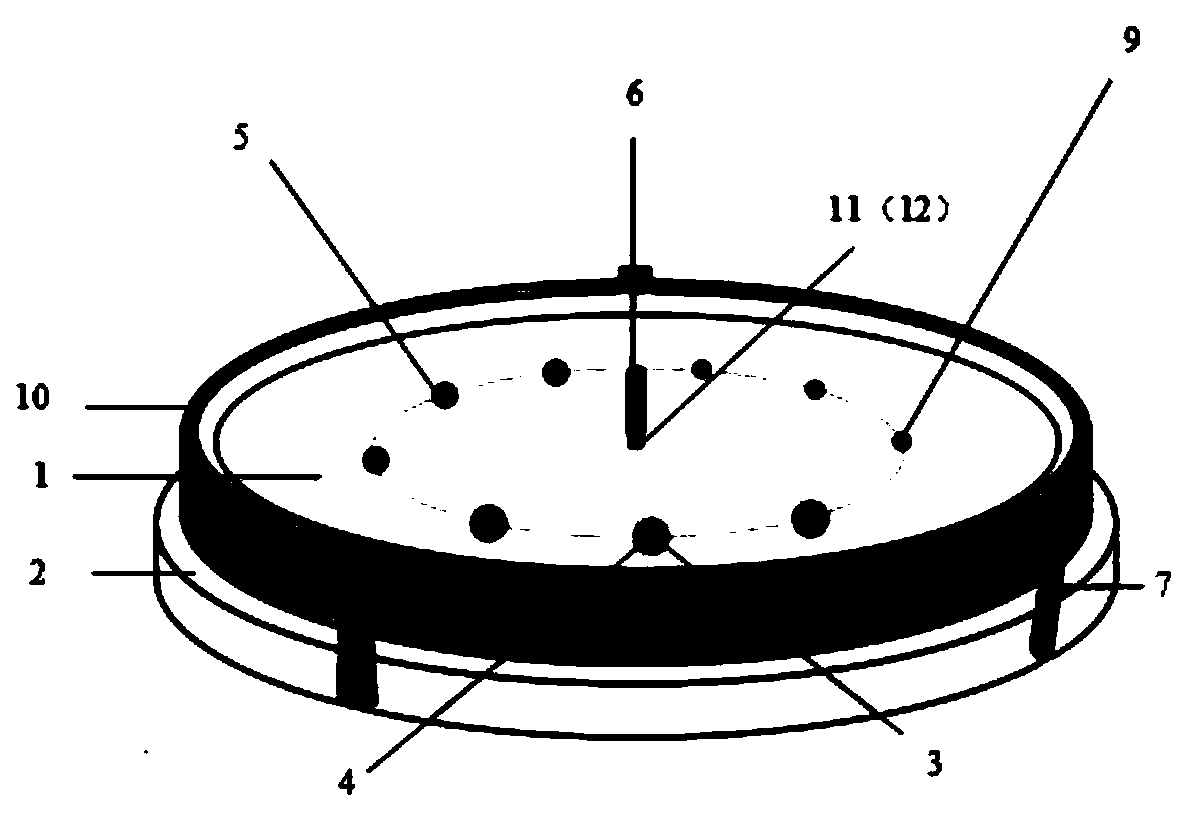

[0020] Such as Figure 1-3 As shown, an operating platform for wrapping tin bag samples of different diameters includes an upper tray, a lower chassis, positioning pins, positioning openings, positioning holes, positioning screws, and positioning screw caps.

[0021] The operating platform is a two-layer structure composed of a plate-shaped upper tray and a plate-shaped lower chassis stacked on top of each other. The upper surface of the upper tray is upwardly provided with a ring-shaped outer edge higher than the plane of the upper surface.

[0022] There are 3 sets of circular blind holes with different diameters as tin capsule positioning holes on the lower chassis. Different sets of tin capsule positioning holes have different diameters: 4mm, 5mm and 6mm. Each set of tin capsule positioning holes consists of 3 The first hole axis of each set of tin bag positioning holes on the same circle B and the first hole axis of the next set of adjacent tin bag positioning holes in the clockw

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap