Road deicing and snow removing machine

A technology for snow blowers and highways, which is used in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of slow deicing speed, slippage, and small size of deicing devices, and achieves the effect of increasing the effective area and saving power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

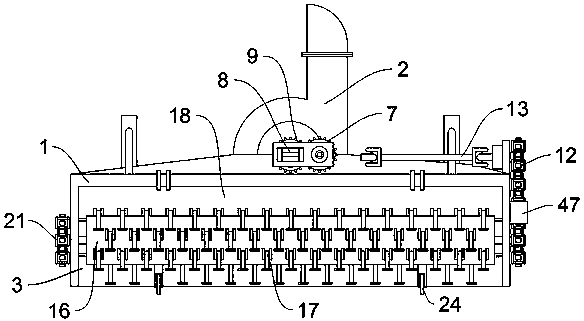

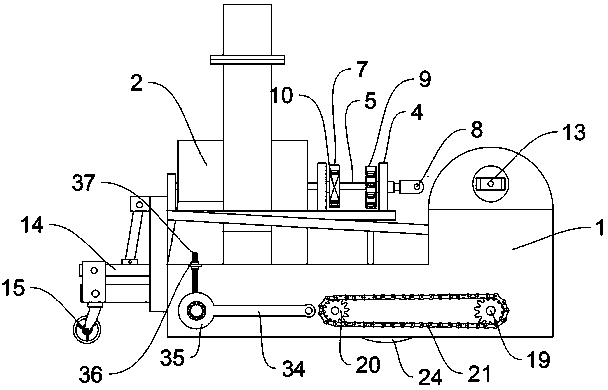

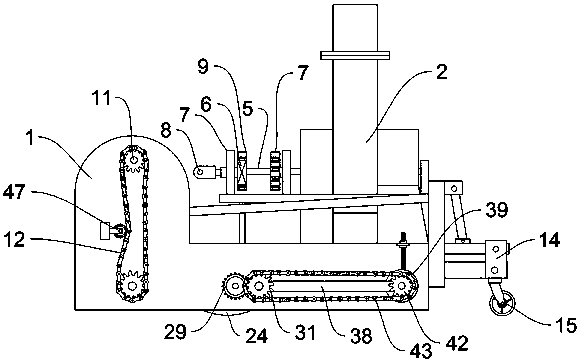

[0027] Embodiment: according to specification Figure 1-6 And 8, it can be seen that, in use, the deicing device is connected on the dragged car body, and the connecting rod 8 and the power shaft 13 are connected with the gearbox on the car body, and the power shaft 13 is connected to the gearbox by the front end universal joint. The horizontal axis is connected, and the connecting rod 8 is connected with the longitudinal axis through the front universal joint (instruction attached Figure 8 ), at this time the deicing device moves, the connecting rod 8 rotates, and makes the third gear 9 rotate, and because the third gear 9 meshes with the first gear 6, the first shaft 5 on the first gear 6 rotates , the second gear 7 rotates at the same time, because the second gear 7 is meshed with the fourth gear 10, so that the fourth gear 10 rotates. The transmission rod 44 drives the ice-discharging blade 46 to rotate, and the power shaft 13 rotates, so that a pair of power gears 11 rotat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap