Suction nozzle electric rising and falling type charging basket dust conveying device

A lift-type, bucket technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, can solve the problems of operator health hazards, secondary environmental pollution, low feeding efficiency, etc., to avoid secondary pollution, reduce Labor intensity and the effect of improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

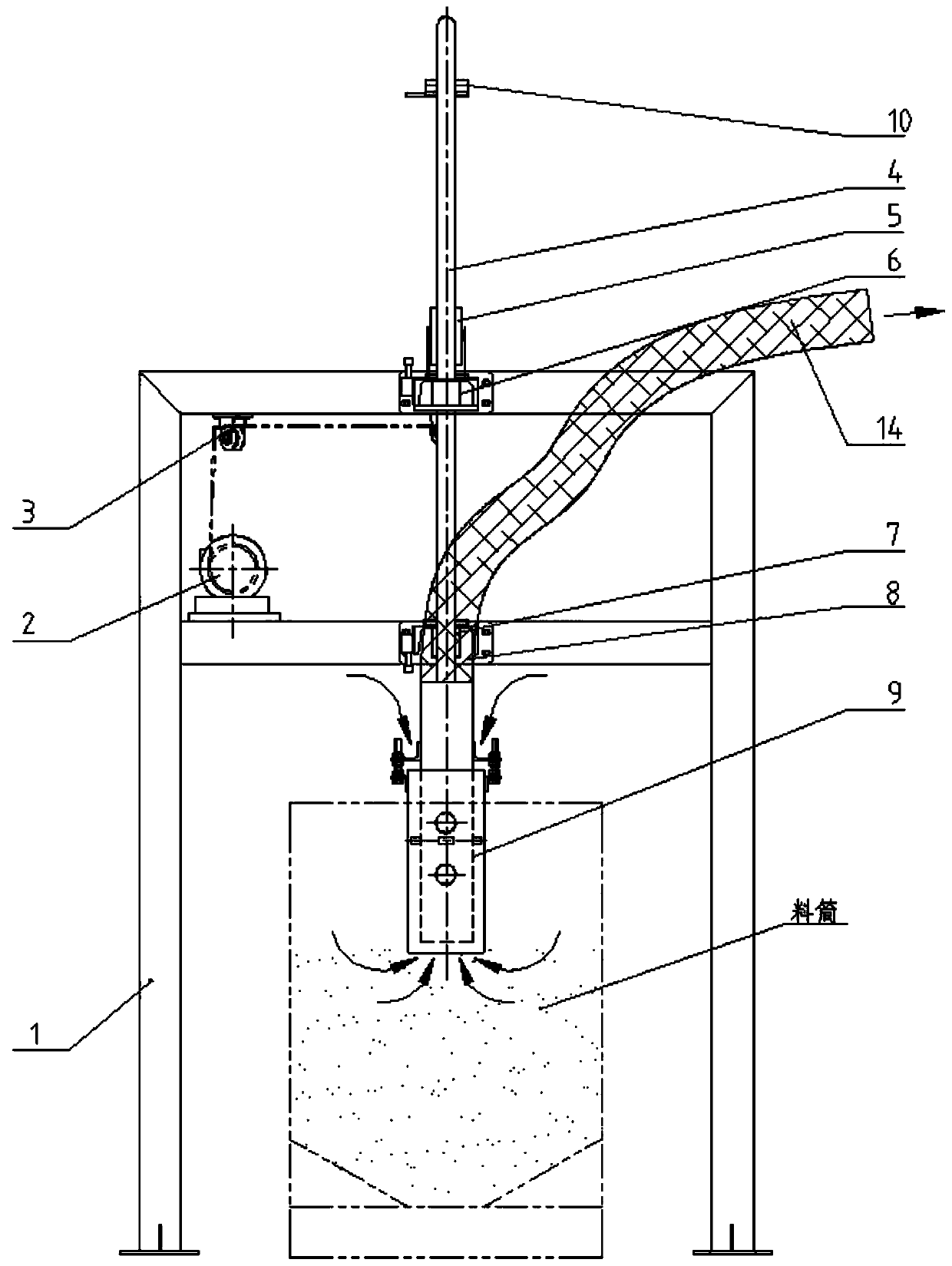

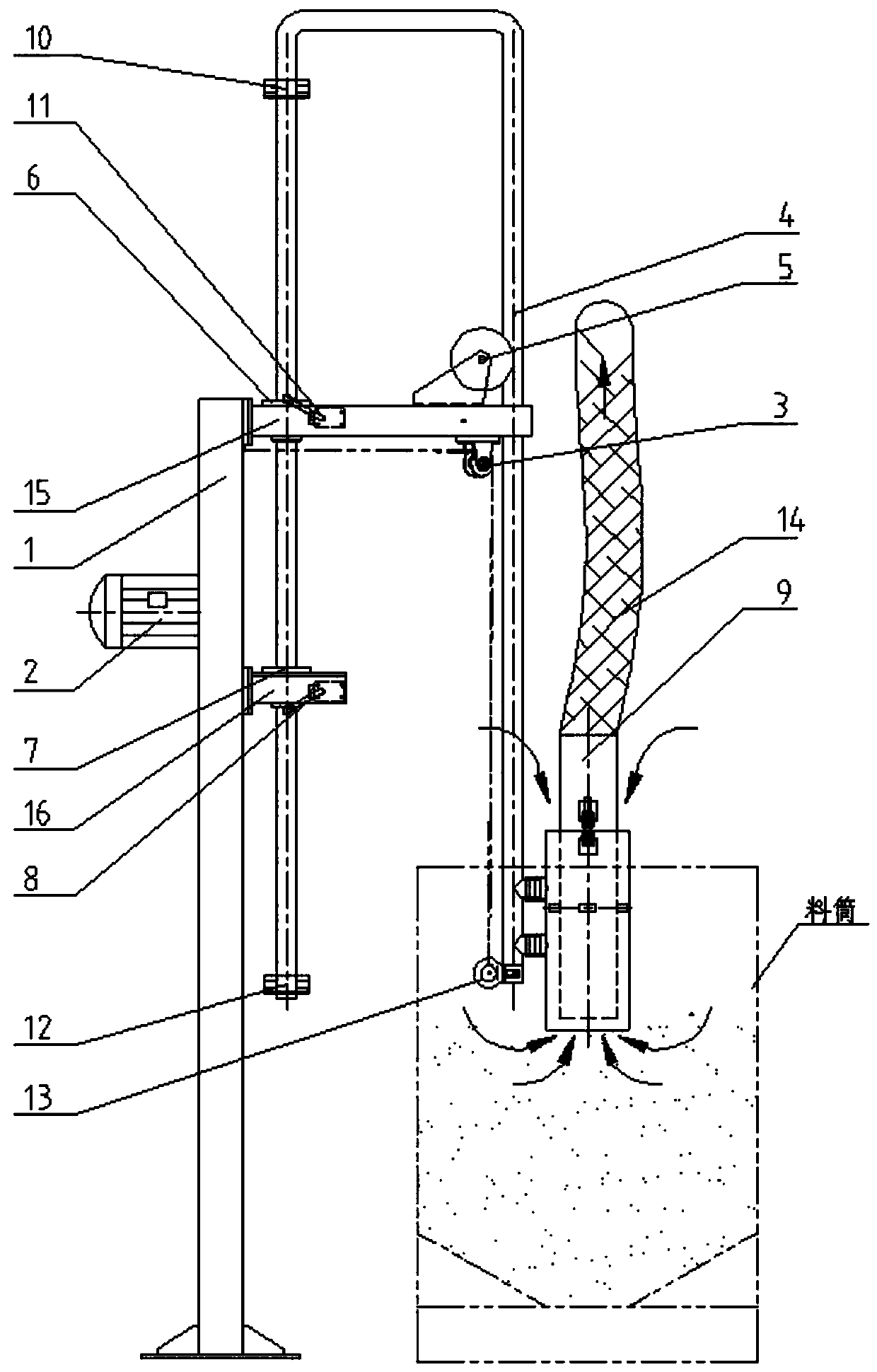

[0014] Combine figure 1 , figure 2 As shown, a suction nozzle electric lifting device for conveying dust in a bucket includes a frame 1, an electric winch 2, a fixed pulley 3, a guide rod 4, a centering roller 5, an upper linear bearing 6, a lower linear bearing 7, and a lower limit Position switch 8, suction nozzle 9, upper limit block 10, upper limit switch 11, lower limit block 12, lifting ring 13, conveying hose 14, upper beam 15, and lower beam 16. The upper beam 15 and the lower beam 16 are respectively cantilevered at one end and fixed on the frame 1 at the other end. The upper linear bearing 6 and the upper limit switch 11 are fixed on the upper beam 15, and the lower linear bearing 7 and the lower limit switch 8 are fixed on the lower beam 16. The centering roller 5 and a pair of fixed pulleys 3 are respectively fixed on the u

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap