Novel mechanical-hydraulic control triaxial creep testing machine

A three-axis creep and testing machine technology, applied in the field of creep testing machines, can solve the problems of inconvenient replacement of the upper force column and the force transmission column sleeve, large loading error, and influence on the test effect, etc., and achieve good comprehensive performance, The test piece is easy to install and the overall structure is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0026] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

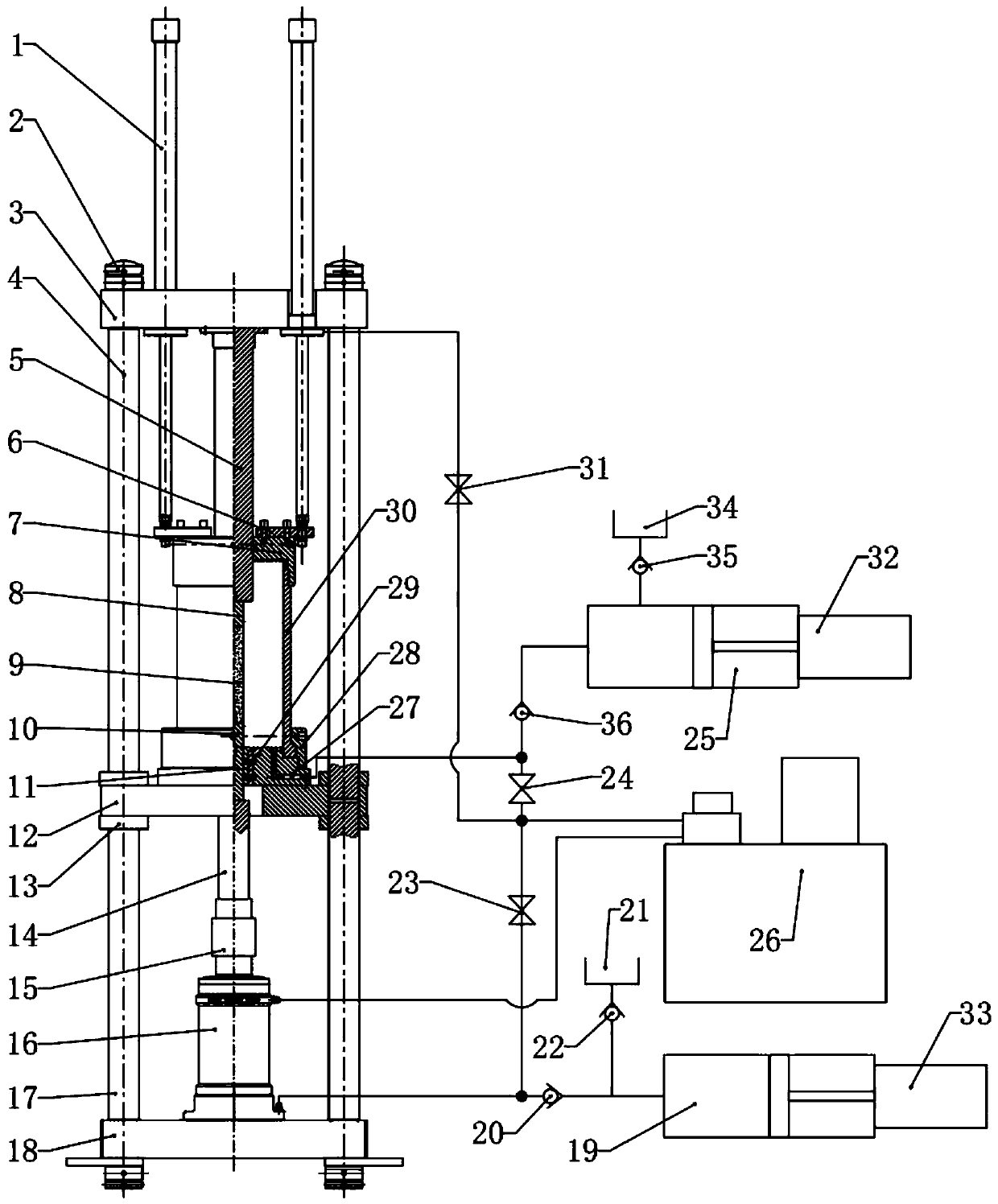

[0027] Such as figure 1 As shown, a new three-axis creep testing machine controlled by mechanical fluid includes an upper bearing plate 3, a middle plate 12 and a lower bearing plate 18; An upper column 4, the two ends of a plurality of the upper columns 4 are respectively connected to the edge of the upper bearing plate 3 and the edge of the middle plate 12; a plurality of lower colum

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap