Coaxial multi-layer multi-stage type self-adaptive two-gear speed control system

A multi-stage, self-adaptive technology, applied in the field of variable speed transmission, can solve the problems of large structure and poor overall force balance, and achieve the effect of compact overall structure, balanced force, and improved mechanical transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

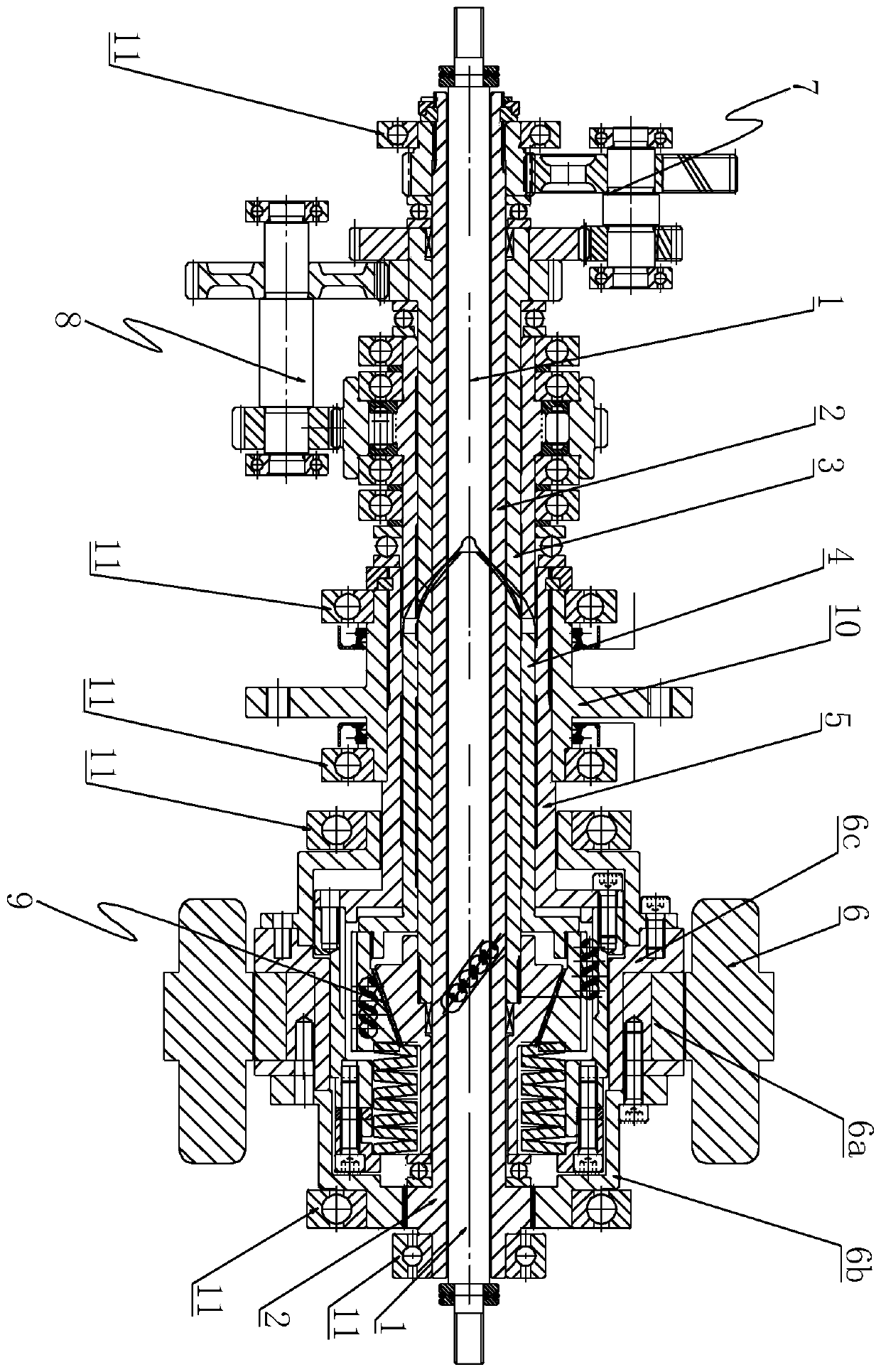

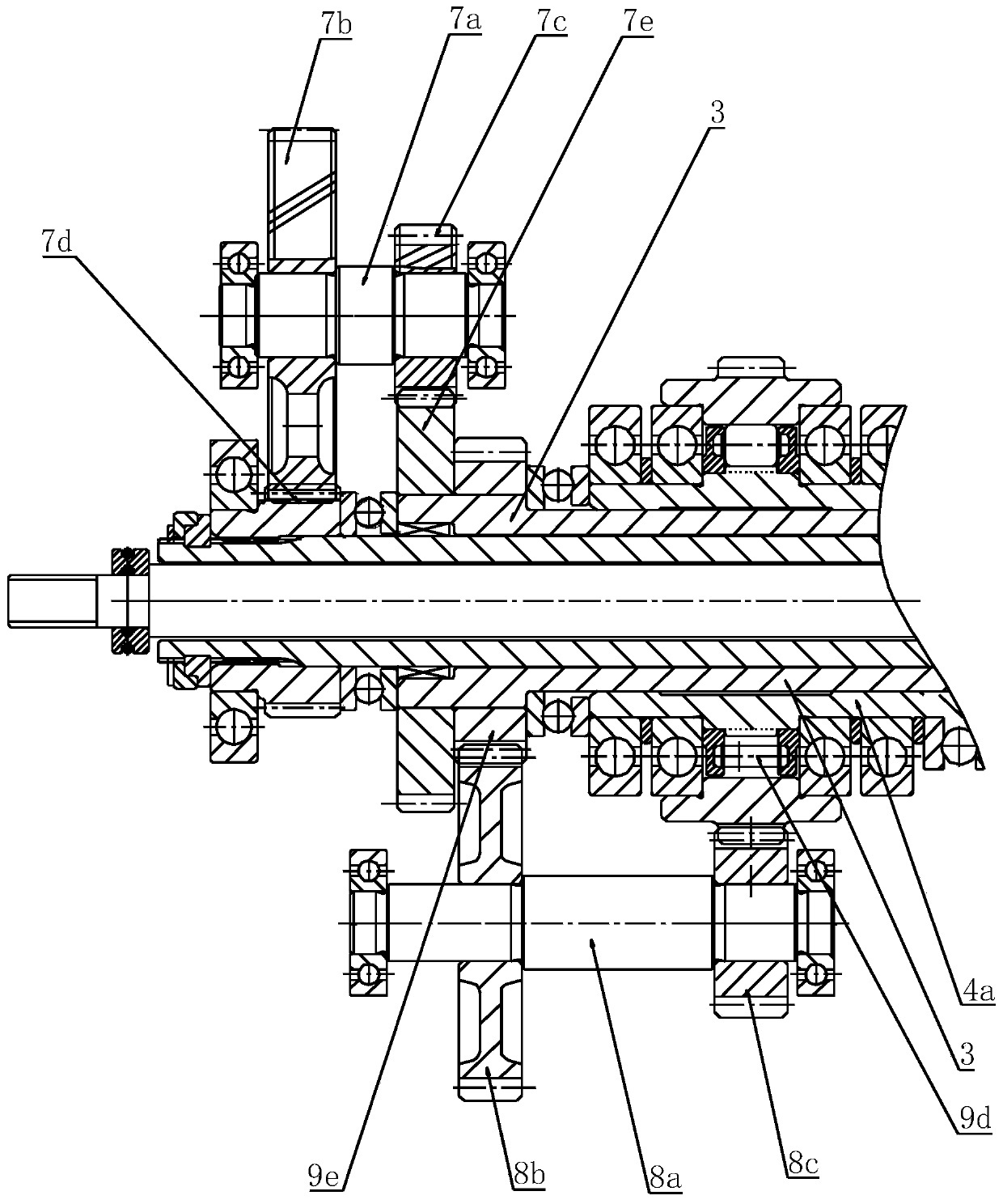

[0026] like figure 1 As shown, a coaxial multi-layer multi-stage adaptive two-speed transmission system, its structure includes a fixed shaft 1, on which the input sleeve 2, the high-speed transmission sleeve 3, and the low-speed transmission sleeve are sequentially rotated from the inside to the outside. 4 and the output sleeve 5, wherein the input sleeve 2 and the high-speed transmission sleeve 3 are dynamically connected through the first reduction mechanism 7, and the high-speed transmission sleeve 3 and the low-speed transmission sleeve 4 are dynamically connected through the second reduction mechanism 8 and the clutch mechanism 9, An output member 10 is set on the output sleeve 5 , and a motor 6 for driving the input sleeve 2 to rotate is provided at the right end of the fixed shaft 1 .

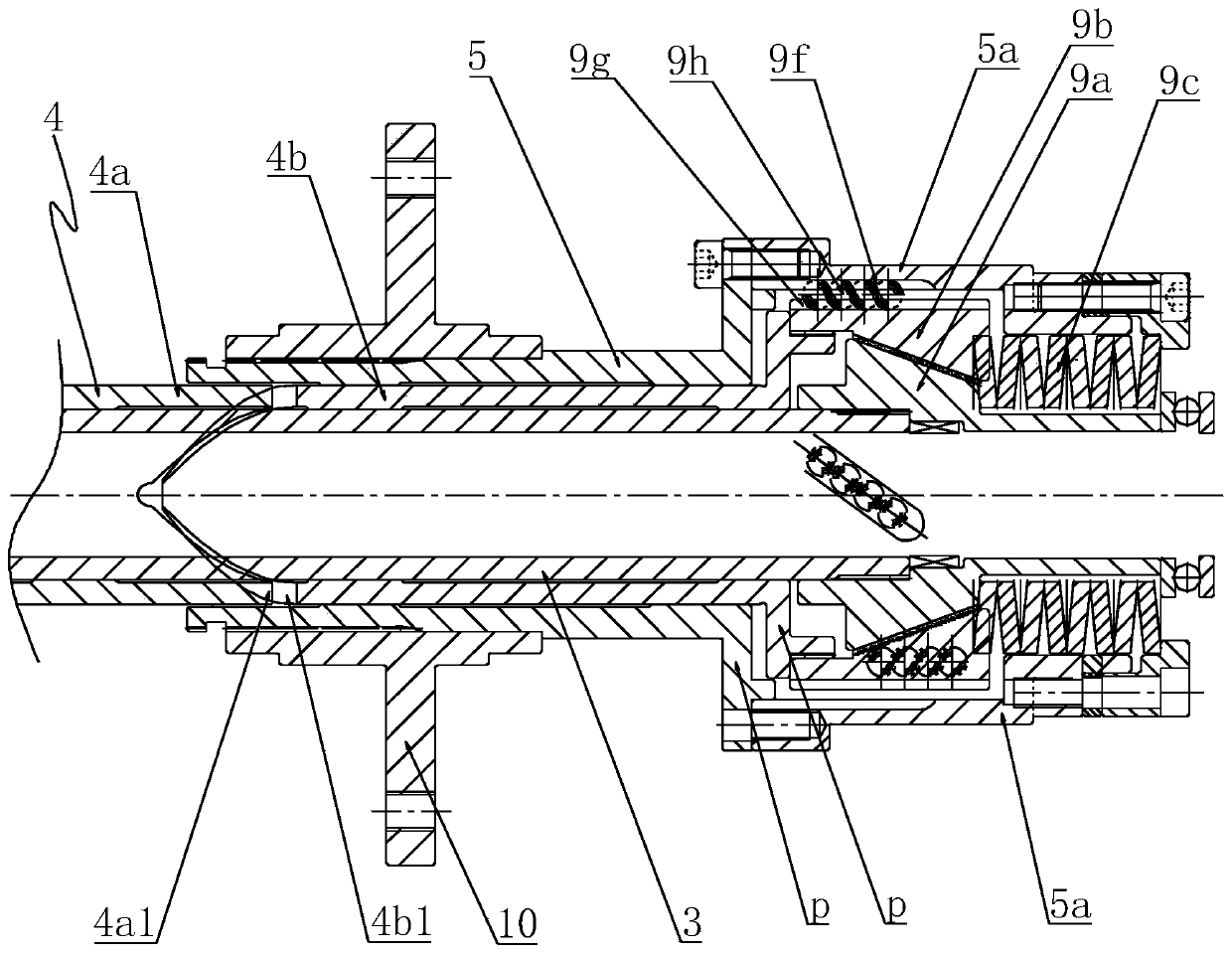

[0027] like image 3 As shown, the clutch mechanism 9 includes an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap