Sulfonated polyethyleneimine and nanofiltration membrane, and preparation methods thereof

A technology of sulfonated polyethyleneimine and polyethyleneimine, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor stability and high cost of loose nanofiltration membranes, and achieve inhibition of interfacial polymerization. Process, mild conditions, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

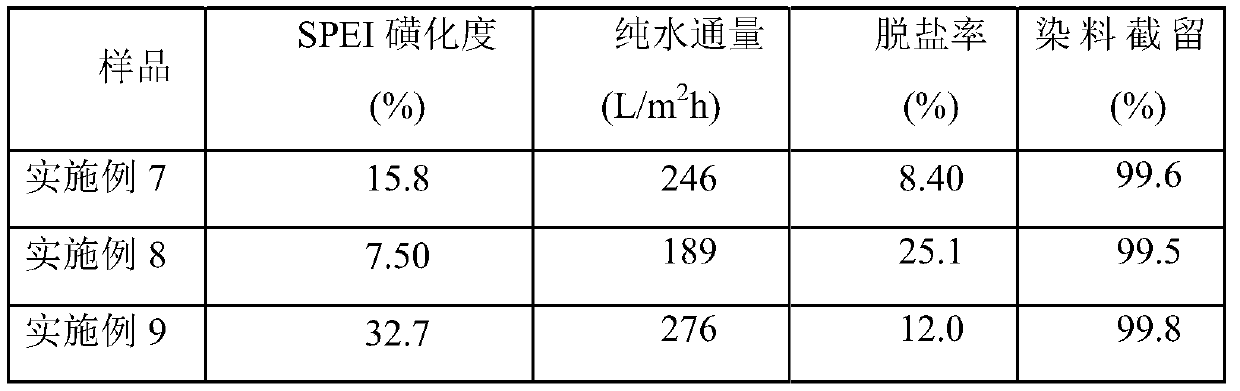

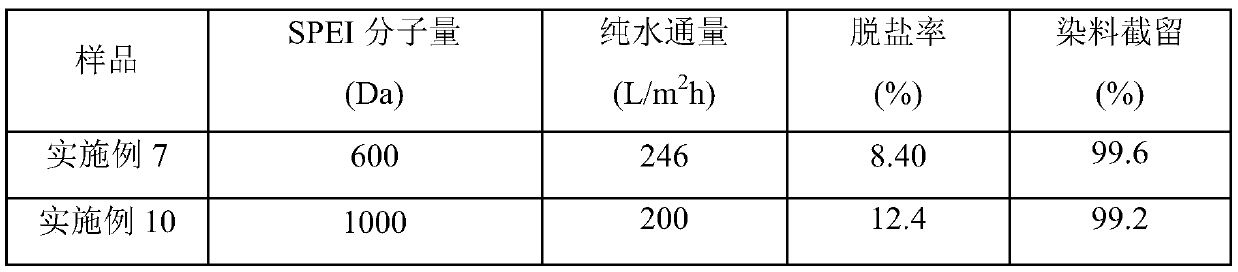

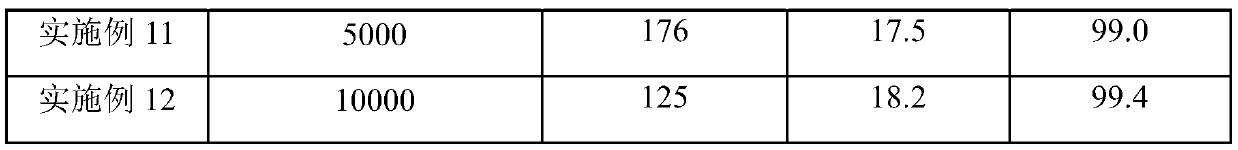

Embodiment 1

[0030] 1 g of polyethyleneimine (PEI, molecular weight: 600 Da, purity: 99%, Shanghai Aladdin Reagent Company) was added into a 100 mL round bottom flask, and then 50 mL of absolute ethanol solution was slowly added. Stir magnetically until the PEI is completely dissolved to obtain a colorless and transparent solution, then add 1 g of 1,3 propane sultone (purity: 99%, Shanghai Aladdin Reagent Company) and 0.416 mL of ammonia solution to the solution in sequence, at 50 ° C After continuing to stir the reaction for 24h, a viscous ethanol solution of sulfonated polyethyleneimine (SPEI) was obtained. Finally, by filtration and freeze-drying, the SPEI solid with a sulfonation degree of 15.8% was obtained and stored in a desiccator.

Embodiment 2

[0032] The difference from Example 1 is that the amount of propane sultone added is 0.5 g, and the sulfonation degree is 7.5%.

Embodiment 3

[0034] The difference from Example 1 is that the amount of propane sultone added is 2 g, and the sulfonation degree is 32.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap