Resonance sheet fixing structure of quartz crystal resonator

A technology of quartz crystal and fixed structure, which is applied to devices, coatings, electrical components and other directions for coating liquid on the surface, which can solve the problems of difficult control of conductive adhesive curing, waste of cost, and stop vibration, so as to avoid spattering of glue spots. The effect of dripping on the resonance sheet, avoiding pulling glue and beach glue, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

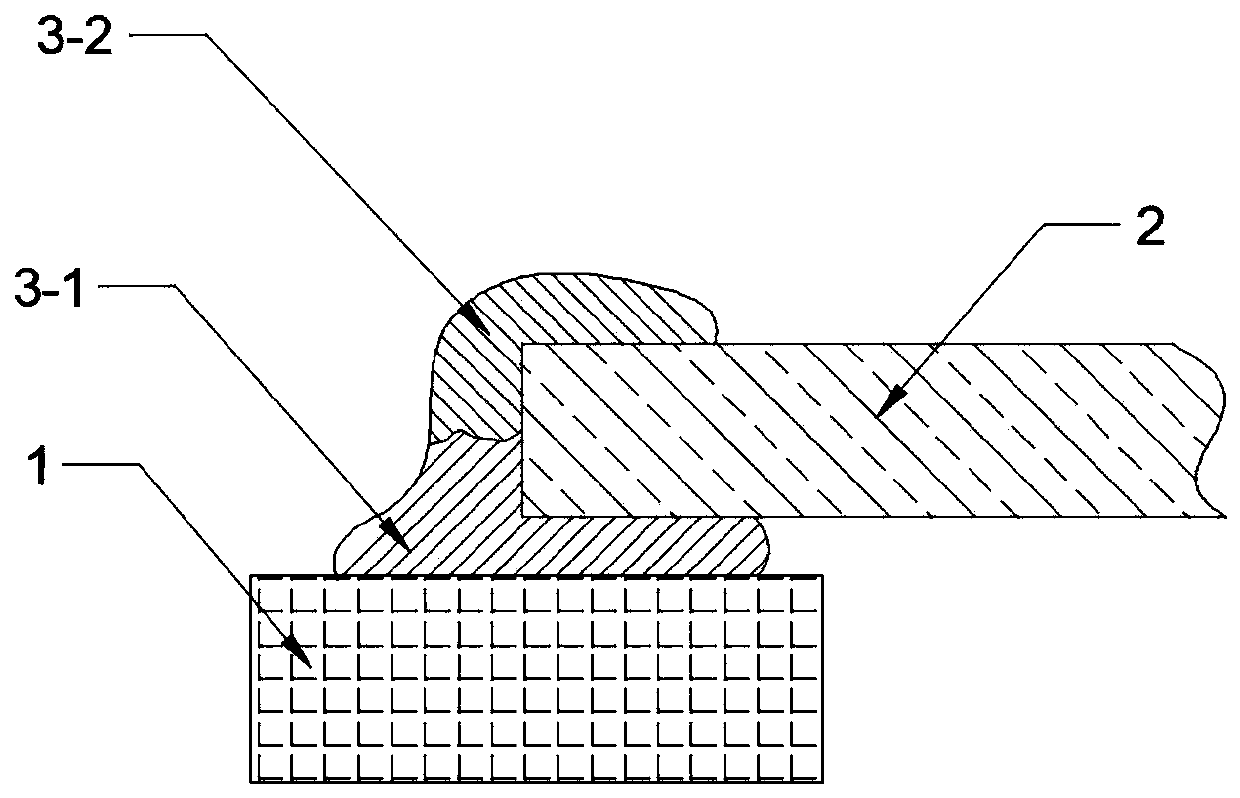

[0024] A resonant plate fixing structure of a quartz crystal resonator, comprising a dispensing platform 1 and a resonating plate 2, one end of the resonating plate 2 is fixed on the dispensing platform 1 by colloid, and the colloid includes a fused bottom Adhesive dots 3-1 and top glue dots 3-2, the bottom glue dots 3-1 are conductive glue, and the top glue dots 3-2 are silica gel.

[0025] The bottom glue point 3-1 and the top glue point 3-2 are blended together at the side of the end of the resonant plate.

[0026] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap