Novel die for car parts

A technology of auto parts and new molds, which is applied in the field of auto parts manufacturing, can solve the problems of complicated operation, unfavorable and effective operation, time-consuming replacement of molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

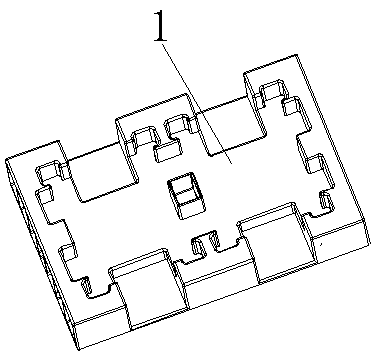

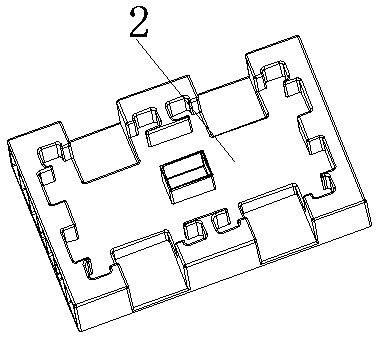

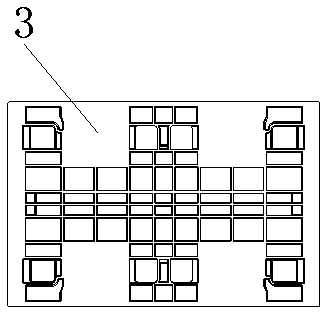

[0022] like Figure 1-3 As shown, the embodiment of the present invention provides a novel mold for auto parts, including a first mold body 1, a second mold body 2, and a third mold body 3, wherein the first mold body 1, the second mold body 2 and the second mold body The three mold bodies 3 are all adapted, wherein the first mold body 1 and the second mold body 2 are functional surface processed bodies.

[0023] A novel mold for auto parts also includes the following steps of use:

[0024] S1. When processing products M and N, design the non-functional surface of the M product and the non-functional surface of the N product into a shape structure corresponding to the third mold body 3;

[0025] S2. Then the surface structure of the first mold body 1 is designed into a shape with the same structure according to the functional surface of the M product, and the surface structure of the second mold body 2 is designed into a shape with the same structure according to the function...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap