Spraying robot explosion-proof cabinet electric control system and control method thereof

A technology of spraying robot and electronic control system, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve problems such as failure to pass explosion-proof certification, low safety factor, short service life, etc., to achieve versatility and resistance. The effect of strong interference ability, high safety factor and work efficiency, simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

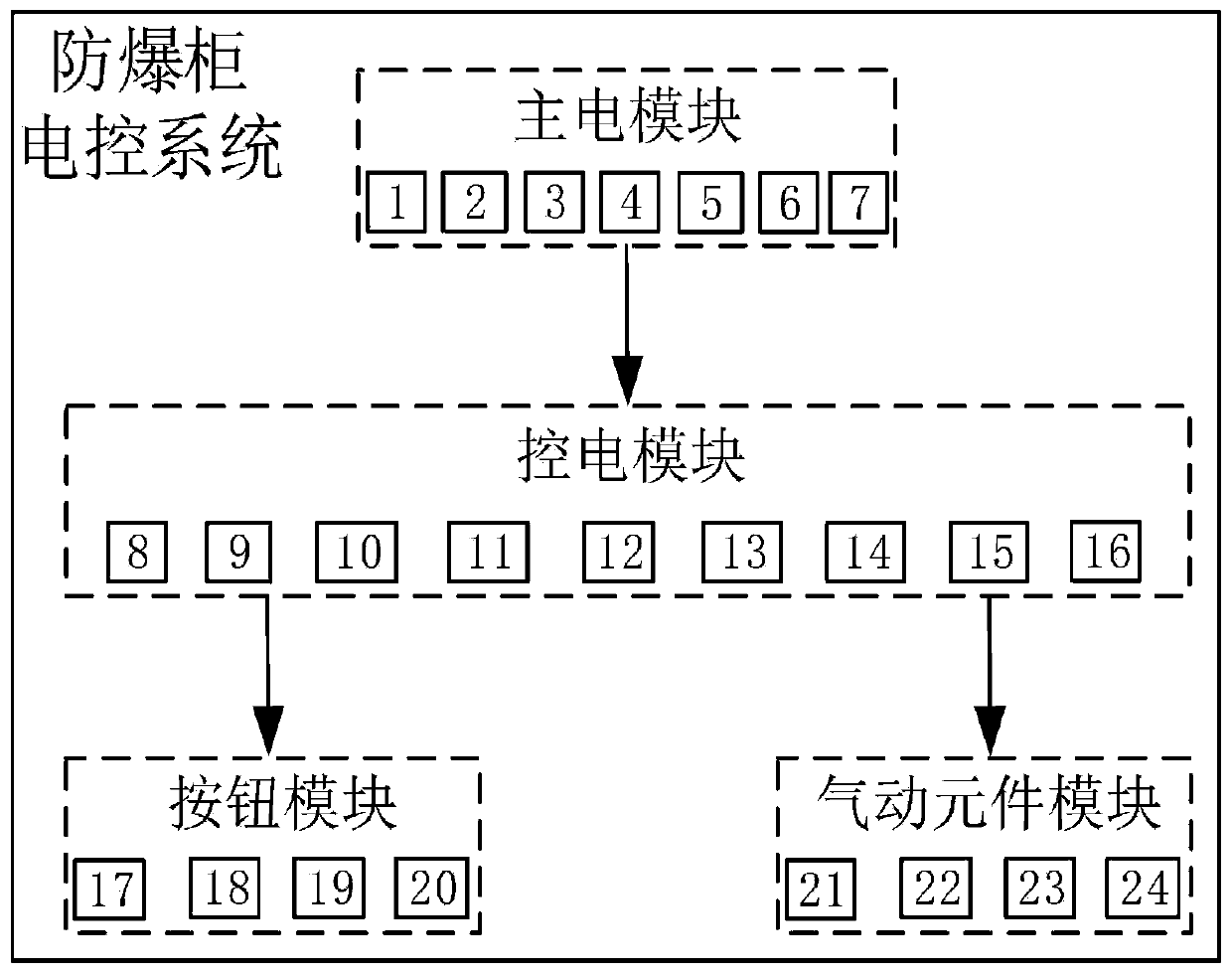

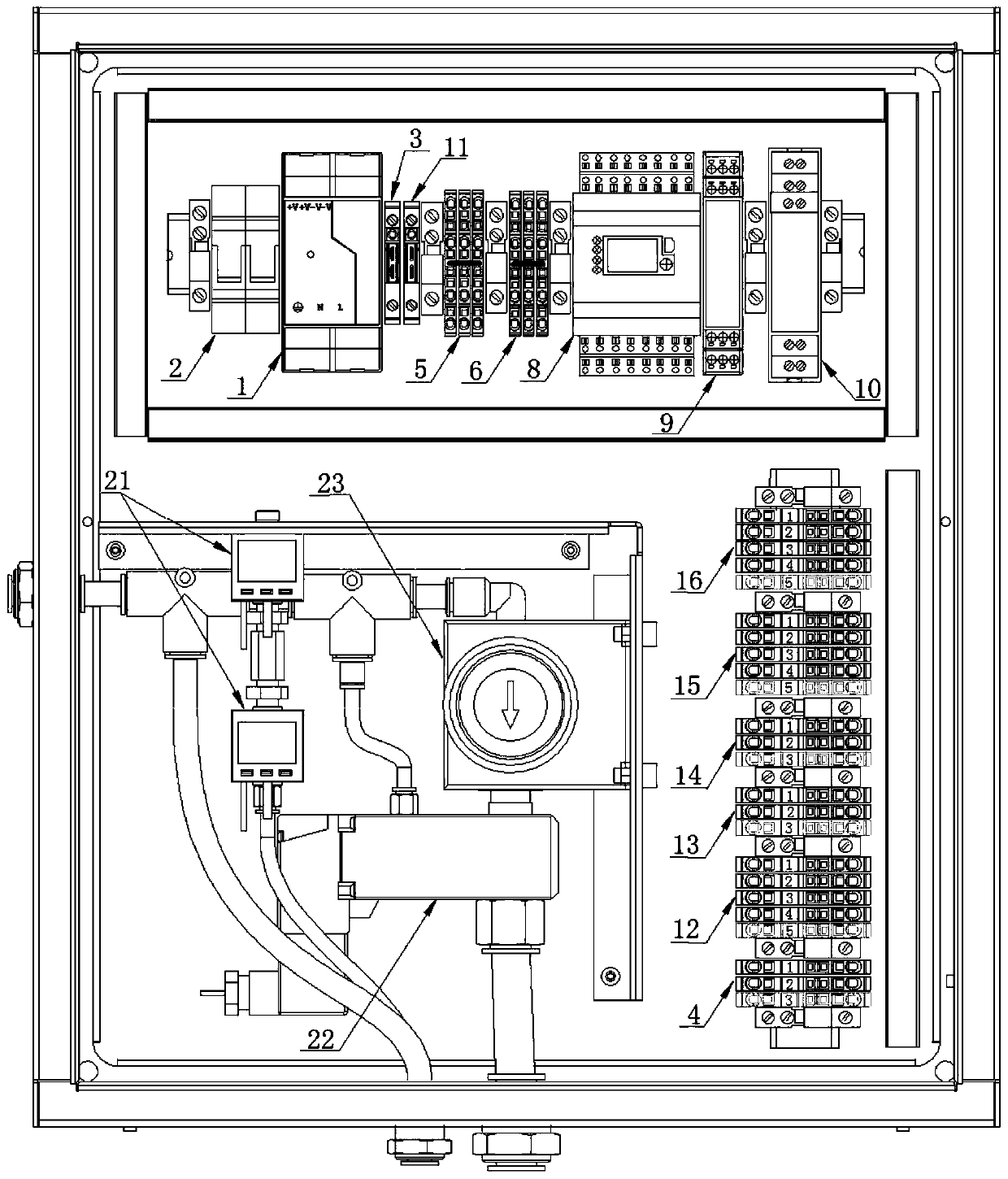

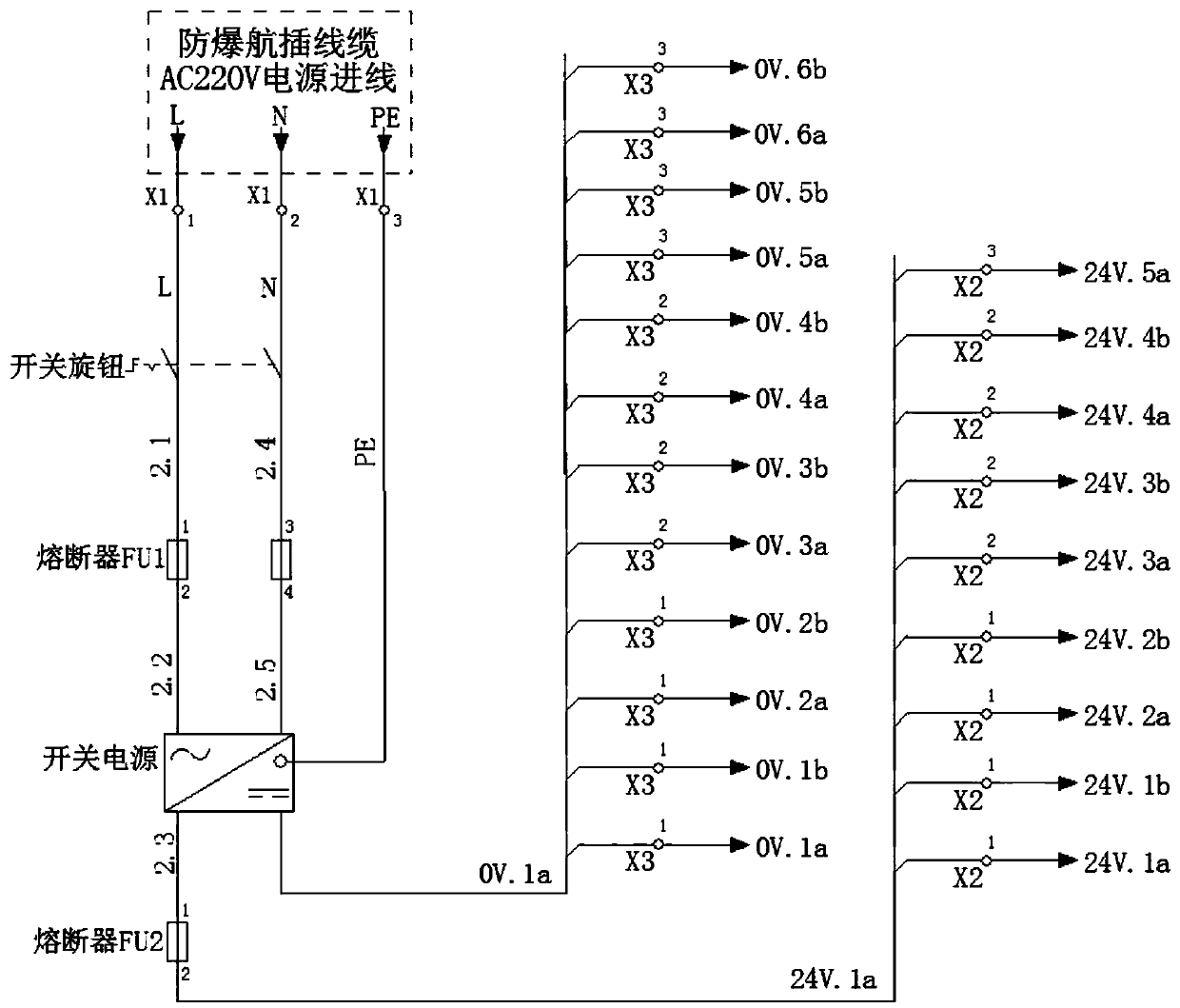

[0041] like figure 1 and figure 2 As shown, a spraying robot explosion-proof cabinet electric control system includes an explosion-proof cabinet connected to the robot, and the explosion-proof cabinet is provided with:

[0042] The main power module is connected with the explosion-proof cabinet to provide power for the components in the explosion-proof cabinet;

[0043] The electrical control module is installed in the explosion-proof cabinet, and is used to control the working status of the components in the explosion-proof cabinet and the on-off of the circuit;

[0044] The button module is set on the inner and outer surfaces of the explosion-proof cabinet to display the working status of the explosion-proof cabinet;

[0045] The pneumatic component module is installed in the robot b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap