Green efficient organic lubricating oil additive and preparation method and application thereof

A lubricating oil additive, organic technology, applied in the direction of additives, organic chemistry, lubricating composition, etc., can solve the problems of reducing the service life of equipment, cumbersome synthesis process, equipment corrosion, etc., achieve excellent anti-wear and friction reduction effect, simple synthesis process , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

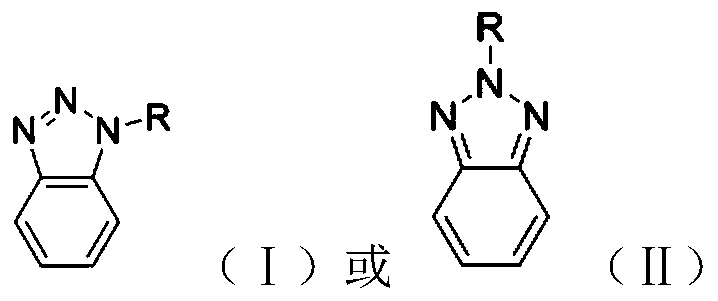

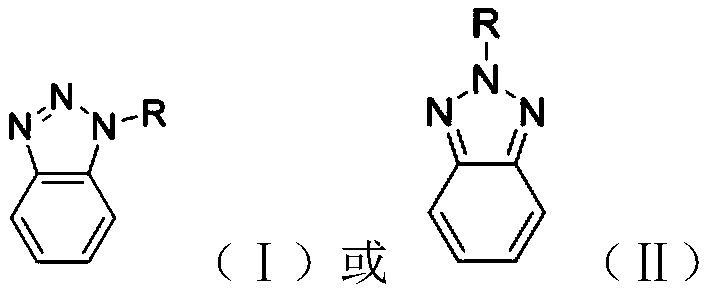

Method used

Image

Examples

Embodiment 1

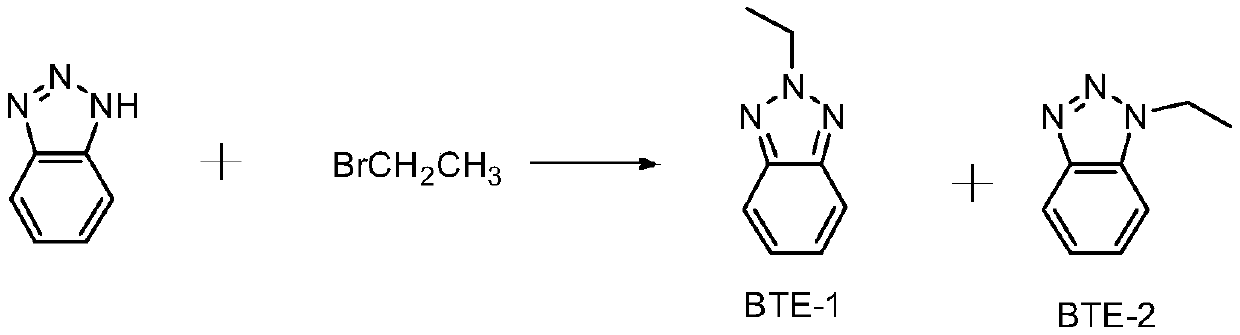

[0026] Dissolve benzotriazole (11.9g, 0.1moL) in 60mL ethanol, add potassium carbonate (13.8g, 0.1moL), react at room temperature for 0.5h, slowly add bromoethane (13.1g, 0.12moL) dropwise, Raise the temperature to 80°C, condense and reflux for 4-8 hours, monitor the reaction process through a silica gel plate during the reaction, stop the reaction when the complete reaction of the benzotriazole is monitored, extract the obtained reactant with water and dichloromethane, and pass the extract through a silica gel column Separation, washing agent adopts the mixed solution of sherwood oil and ethyl acetate (by volume ratio, sherwood oil: ethyl acetate=16:1), separates and obtains target product, removes washing agent by rotary evaporation, dry in vacuum oven, finally Additive BTE-1 and additive BTE-2 were obtained. The reaction formula is as follows:

[0027]

Embodiment 2

[0029] Dissolve benzotriazole (11.9g, 0.1moL) in 60mL ethanol, add potassium carbonate (13.8g, 0.1moL), react at room temperature for 0.5h, slowly add bromodecane (26.5g, 0.12moL), Raise the temperature to 80°C, condense and reflux for 4-8 hours, monitor the reaction process through a silica gel plate during the reaction, stop the reaction when the complete reaction of the benzotriazole is monitored, extract the obtained reactant with water and dichloromethane, and pass the extract through a silica gel column Separation, washing agent adopts the mixed solution of sherwood oil and ethyl acetate (by volume ratio, sherwood oil: ethyl acetate=8:1), separates and obtains target product, removes washing agent by rotary evaporation, dry in vacuum oven, finally Additive BTD-1 and additive BTD-2 were obtained. The reaction formula is as follows:

[0030]

Embodiment 3

[0032] Dissolve benzotriazole (11.9g, 0.1moL) in 60mL of absolute ethanol, add potassium carbonate (13.8g, 0.1moL), react at room temperature for 0.5h, slowly add hexadecane bromide (36.6g, 0.12moL ), heat up to 80°C, reflux for 4 to 8 hours, monitor the reaction process through a silica gel plate during the reaction, stop the reaction when the complete reaction of the benzotriazole is monitored, and extract the obtained reactant with water and dichloromethane, and the extract is passed through Silica gel column separation, washing agent adopts the mixed solution of sherwood oil and ethyl acetate (by volume ratio, sherwood oil: ethyl acetate=4:1), separates and obtains target product, removes washing agent by rotary evaporation, and dries in vacuum oven , finally get additive BTH-1 and additive BTH-2. The reaction formula is as follows:

[0033]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap