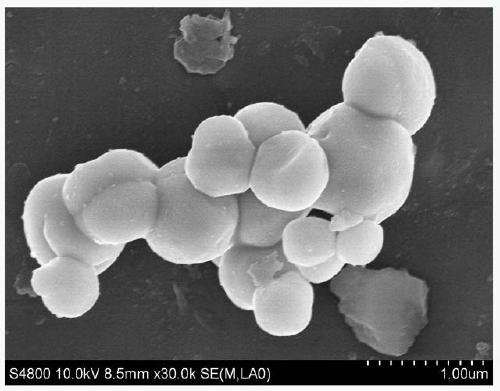

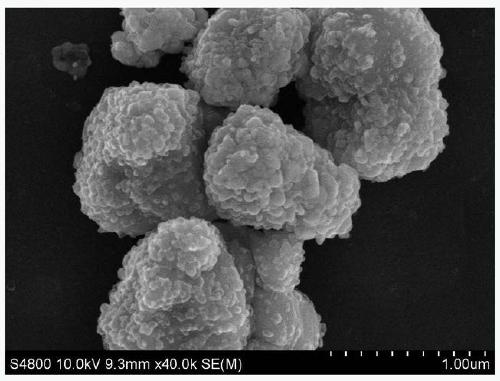

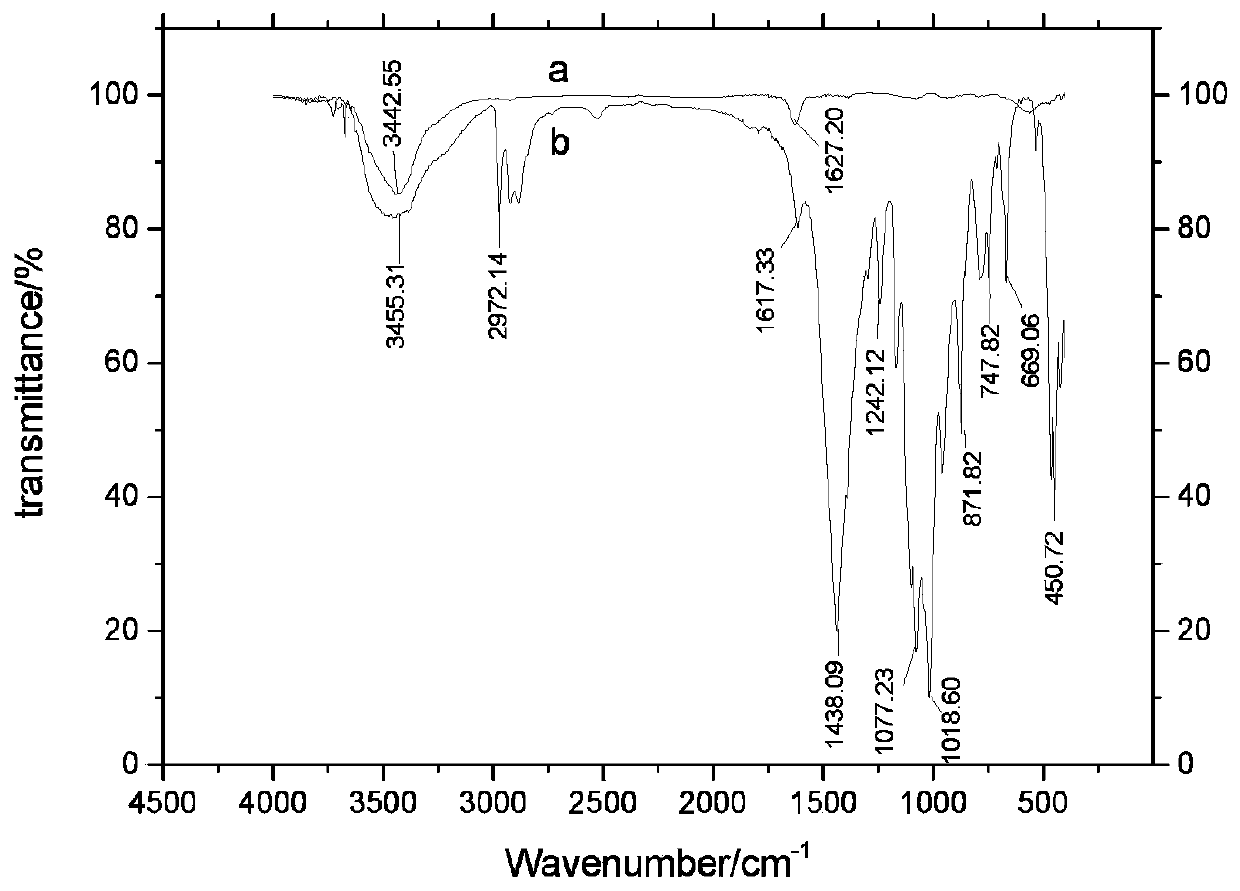

Preparation method of AgX@Ag core-shell electrode material

An electrode material, core-shell technology, applied in the field of electrode material preparation, can solve the problems affecting the content and electrode reaction, affecting the accuracy of test results, electrode potential drift, etc., to achieve regular morphology, small particle size, and uniform nucleation dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific process of an AgX@Ag core-shell electrode material preparation method involved in this embodiment includes four steps: preparation of silver halide powder, pretreatment of silver halide powder, preparation of modified silver halide powder and preparation of core-shell electrode material:

[0023] (1) Preparation of silver halide powder: 20ml of 0.025mol / L AgNO 3 Mix with 0.034g cetyltrimethylammonium bromide to form solution A, mix 0.03g NaCl, 0.01g NaBr and 20ml deionized water to form solution B, and ultrasonicate solution A and solution B for 10min, respectively Stir magnetically at a speed of 900r / m for 10min, slowly add solution B to solution A with a rubber dropper, the dropping process lasts for 10min, react for 2 hours at 25°C under dark conditions, and centrifuge and dry to obtain silver halide powder ;

[0024] (2) Pretreatment of silver halide powder: put 0.6g of silver halide powder prepared in step (1) and 100mL of distilled water in a 250mL

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap