Liquid evaporation, concentration and drying integrated treatment method

A treatment method and liquid evaporation technology, applied in chemical instruments and methods, evaporation, separation methods, etc., can solve the problems of clogging the centrifuge filter screen, centrifuge fouling, and high water content of solids, and achieve energy reduction. demand, improving drying efficiency, and the effect of low solid water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

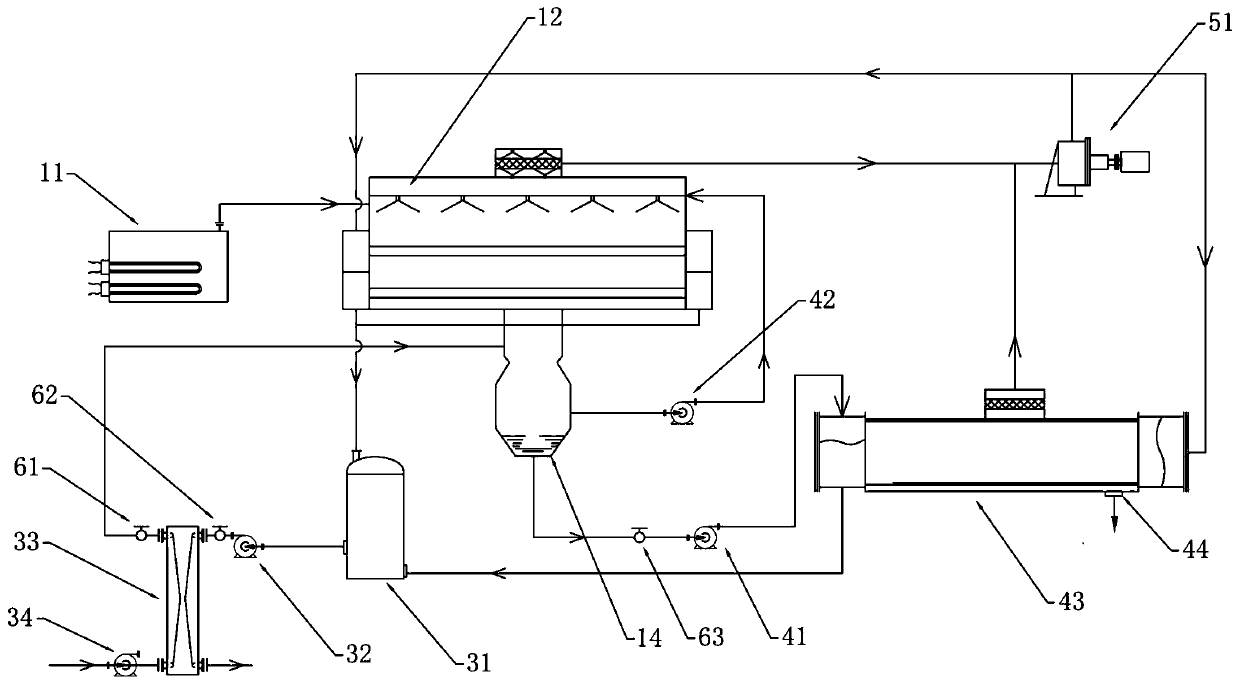

[0038] A liquid evaporation concentration drying treatment device, including an evaporator 12, a circulation pump 42, and a distilled water tank 31, the steam inlet of the evaporator 12 is connected with an external steam pipeline, and the distilled water outlet of the evaporator 12 is connected with the water inlet of the distilled water tank 31 The heat well 14 is connected to the bottom of the evaporator, the circulation outlet of the heat well 14 is connected with the water inlet of the circulation pipe of the evaporator 12 through the circulation pump 42, and the raw liquid water inlet of the heat well 14 is connected with an external pipeline.

[0039] The device also includes a drier 43 and a concentrated liquid pump 41. The concentrated liquid outlet of the hot well 14 is connected to the water inlet of the drier 43 through the concentrated liquid pump 41, and the water outlet of the drier 43 is connected to the distilled water tank 31. The second water inlet is connected,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap