Conical barrel type semi-solid metal manufacturing device and use method thereof

A technology of semi-solid metal and preparation equipment, which is applied in the field of cone-type semi-solid metal preparation equipment, which can solve the problems of poor processing effect and small shear force, and achieve the effect of improving the use effect and increasing the shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

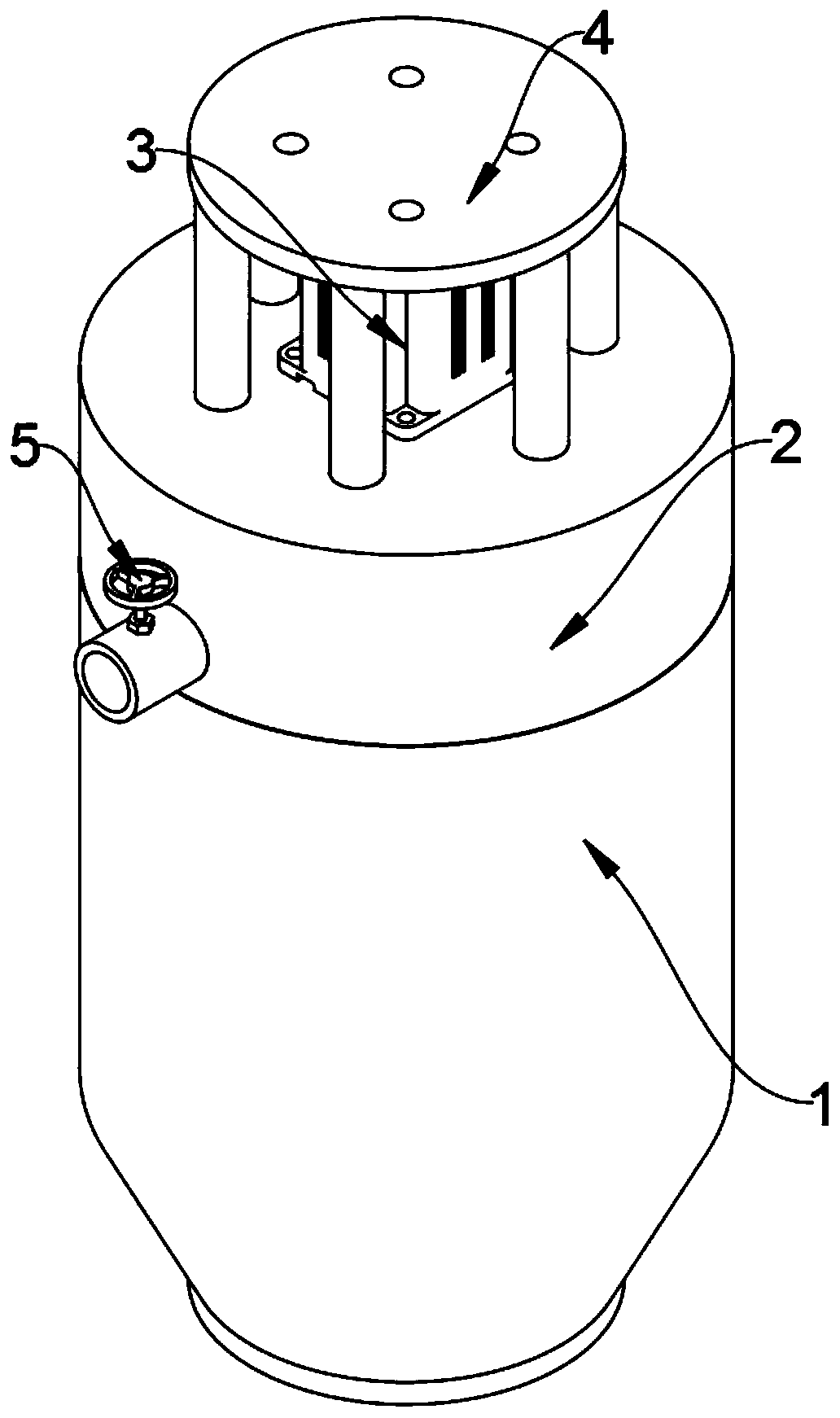

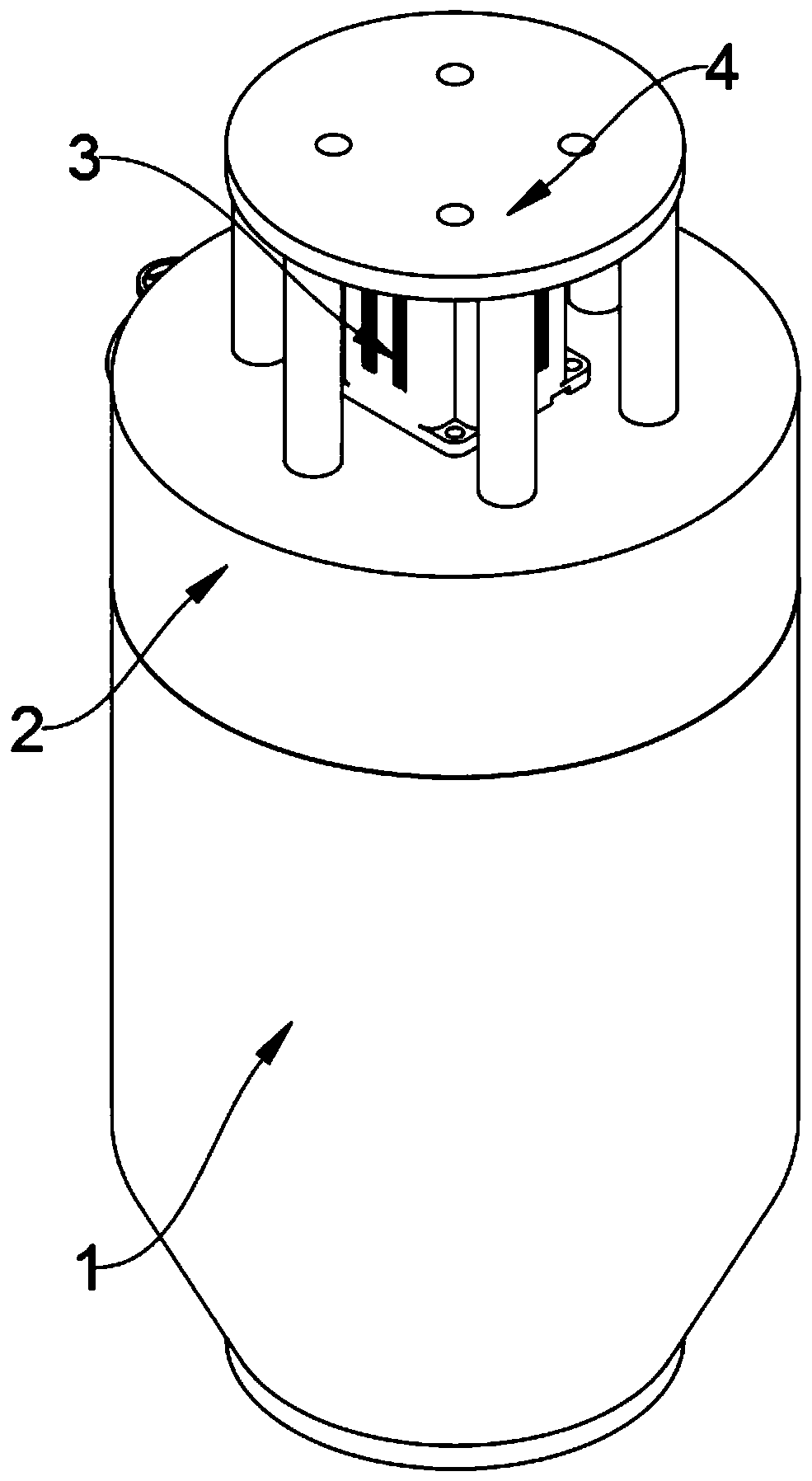

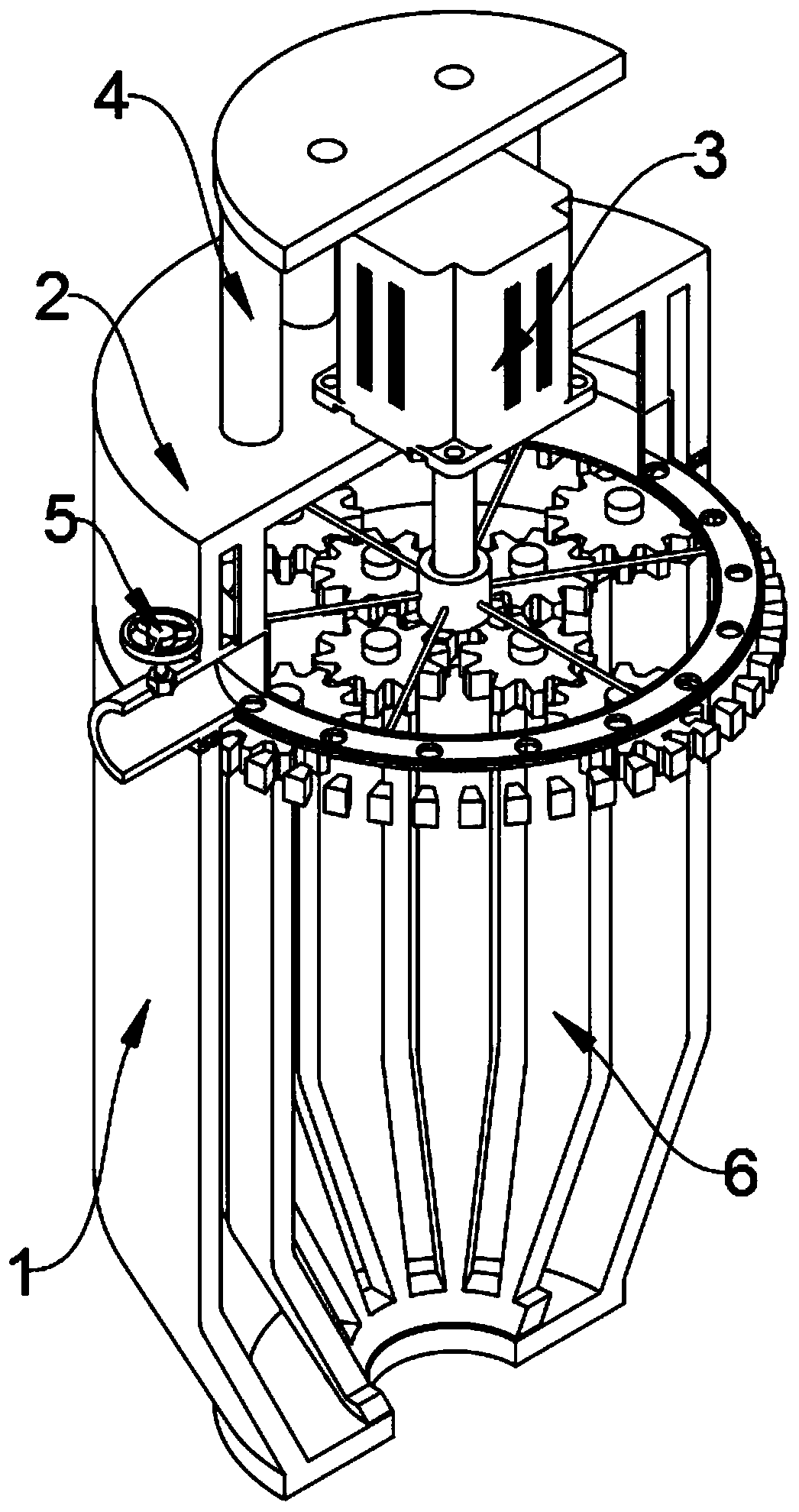

[0036] refer to Figure 1-7 , a cone type semi-solid metal preparation device, comprising a material storage mechanism 1, the material storage mechanism 1 includes a first protective shell 101, a rotating ring 102, a material storage outer cavity 103 and a first discharge port 104, the first protective shell The upper end of 101 is welded with a rotating ring 102, the inside of the first protective shell 101 is provided with a material storage outer chamber 103, and the lower end of the first protective shell 101 is provided with a first discharge port 104, which also includes:

[0037] see Figure 1-5 , the feeding mechanism 2 is located at the upper end of the storage mechanism 1, the feeding mechanism 2 includes a second protective shell 201, an annular feeding pipe 202, a positioning groove 203, a feeding pipe 204, a rotating bottom plate 205, a rotating bracket 206, and a feeding The hole 207 and the connecting rod 208, the lower end of the second protective shell 201 are p

Embodiment 2

[0042] On the basis of the first embodiment, a method for using a cone-barrel semi-solid metal preparation device is disclosed, the steps of which are as follows:

[0043] Step 1: Fix the device on the upper end of the matching lifting mechanism, and then start the lifting mechanism to adjust the position of the device;

[0044] Step 2: Start the servo motor 301 through an external power source electrically connected to the lead wire of the servo motor 301. After the servo motor 301 starts, it will drive the processing mechanism 6 and the second gear 305 to rotate forward through the transmission shaft 302, because the second gear 305 and the third gear 308 are connected by teeth, and when the second gear 305 rotates forward, it will drive the third gear 308 to rotate reversely, because the third gear 308 and the first gear 304 are connected by teeth, and the third gear When 308 rotates reversely, it will drive the first gear 304 to rotate forward, because the first gear 304 and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap