Recycled aggregate mixture and application thereof

A technology of recycled aggregates and mixtures, applied in solid waste management, sustainable waste treatment, pavement details, etc., can solve the problems affecting the performance and service life of the pavement, reflection cracks on the surface of the asphalt layer, and high environmental damage. Achieve the effect of saving production costs, reducing dosage and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1:

[0035] A recycled aggregate mixture is composed of ordinary Portland cement, recycled aggregate, primary aggregate and primary stone powder, wherein:

[0036] The primary aggregate content is 35%-43%;

[0037] The content of the regenerated aggregate is 18%-25%;

[0038] Described primary stone powder content is 25%-27%;

[0039] The content of the regenerated stone powder is 12%-15%.

[0040] In a preferred solution, the primary aggregate has a particle size of 5mm-37.5mm, an apparent density of 2.616-2.626g / cm³, and a mud content of 0.5-1.5%.

[0041] In a preferred solution, the regenerated aggregate has a particle size of 5mm-37.5mm, an apparent density of 2.590-2.611g / cm³, and a mud content of 0.7-1.7%.

[0042] In a preferred solution, the particle size of the rough stone powder is 0-5mm, the apparent density is 2.596g / cm³, and the mud content is 3.4%.

[0043] In a preferred solution, the re-stone powder has a particle size of 0-5mm, an appar

Example Embodiment

[0044] Example 2:

[0045] The pavement structure based on the recycled aggregate mixture described in Example 1 is as follows:

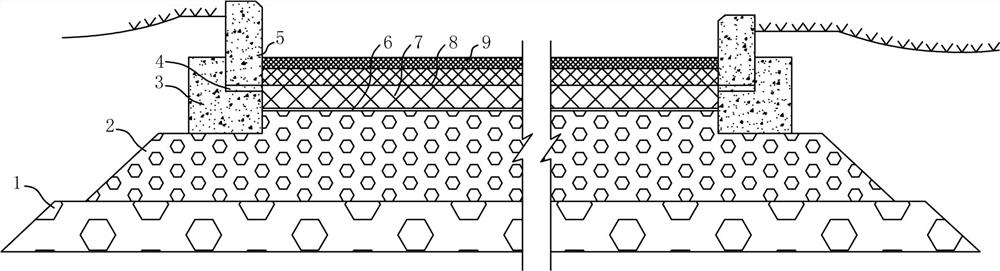

[0046] Two layers of recycled aggregate mixture are spread on the compacted soil base to form a sub-base 1 and a base 2, a concrete cushion 3 is poured on both sides of the base 2, and a cement mortar 4 is poured above the concrete cushion 3, and then the vertical teeth 5 are set. Between the vertical teeth 5 on both sides of the base layer 2, from bottom to top, emulsified asphalt permeable layer 6, coarse-grained asphalt concrete 7, medium-grained modified asphalt concrete 8 and asphalt mastic crushed stone mixture 9 are sequentially paved.

Example Embodiment

[0047] Example 3:

[0048] The specific ratio of the sub-base 1 and the base 2 and the cement content are determined through experiments:

[0049] The sub-base layer 1 is paved with 4% cement-stabilized recycled aggregate mixture (the cement content is 4%), and the base layer 2 is paved with 5% cement-stabilized recycled aggregate mixture (the cement content is 5%).

[0050] Specifically, in the sub-base 1, the recycled aggregate mixture is a 4% cement-stabilized recycled aggregate mixture, including:

[0051] Primary aggregate, the particle size is 5mm-37.5mm, the content is 35%, the apparent density is 2.616-2.626g / cm³, and the mud content is 0.5-1.5%;

[0052] Recycled aggregate, particle size is 5mm-37.5mm, content is 25%, apparent density is 2.590-2.611g / cm³, and mud content is 0.7-1.7%;

[0053] Primary stone powder, particle size 0-5mm, content of 25%, apparent density of 2.597g / cm³, and mud content of 3.2%;

[0054] Recycled stone powder, particle size 0-5mm, con

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap