Device and method for preparing antimony beads

An antimony bead and molding device technology, which is applied in the field of metal particle preparation, can solve the problems of high energy consumption and complex process, and achieve the effects of low operation energy consumption, simple process and high molding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

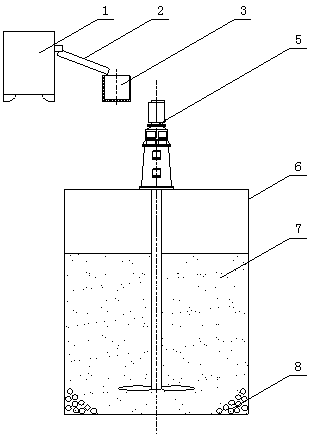

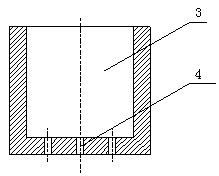

[0027] refer to figure 1 and figure 2 The device for preparing antimony beads in this embodiment includes an antimony block raw material melting furnace 1 and an antimony bead forming device, and a diversion groove 2 and a material storage tank 3 are arranged between the antimony block raw material melting furnace 1 and the antimony bead forming device, The antimony block raw material melting furnace 1, the diversion tank 2 and the storage tank 3 are all arranged above the antimony bead forming device, and the bottom of the storage tank 3 is provided with a discharge hole 4 along the radial direction, so that The antimony bead forming device includes an emulsification barrel 6, and the emulsification barrel 6 is provided with an agitator 5, and the agitator 5 is equipped with a frequency conversion speed regulating device.

[0028] The outer sides of the antimony block raw material melting furnace 1 , diversion tank 2 and storage tank 3 are provided with insulation layers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap