Industrial VOCs waste gas treatment equipment and method

A kind of waste gas treatment equipment, industrial technology, applied in gas treatment, separation method, auxiliary pretreatment and other directions, to achieve the effect of strong penetration force, radiation force, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are only some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other implementations obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

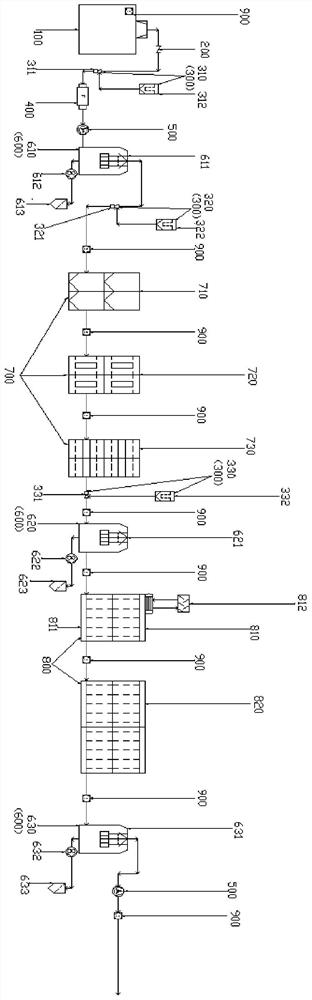

[0027] see figure 1 , The present invention provides an industrial VOCs waste gas treatment equipment, including a pretreatment device, a VOCs treatment device 700 and an ozone treatment device 800, wherein the pretreatment device, the VOCs treatment device 700 and the ozone treatment device 800 are connected by pipelines. The VOCs waste gas in the production workshop 100 (the production workshop 100 can be a workshop with VOCs gas pollution in the production process of petrochemical,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap