Wagon emergency connecting device and mounting structure thereof

A technology for connecting devices and railway freight cars, applied in railway car body parts, railway vehicle coupling accessories, traction devices, etc., can solve the problems of disconnection failure, inconvenient disassembly and assembly, low strength, etc., and achieves reduced blockage and convenient installation. , the effect of quick rescue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

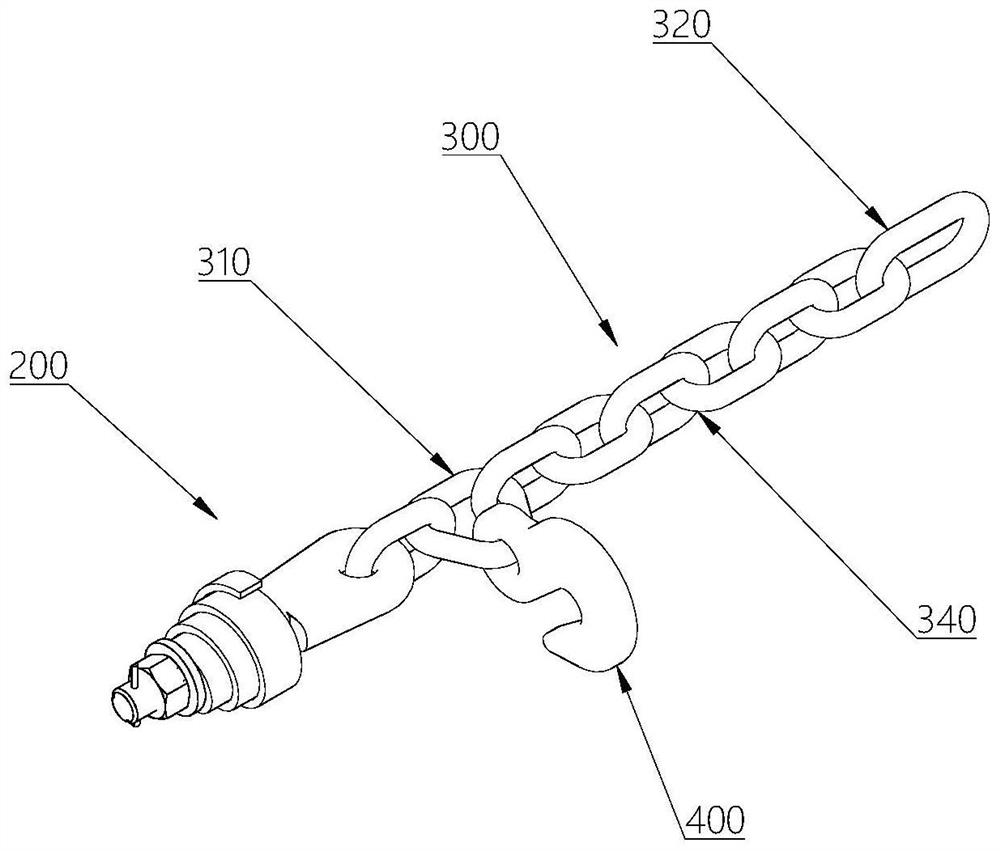

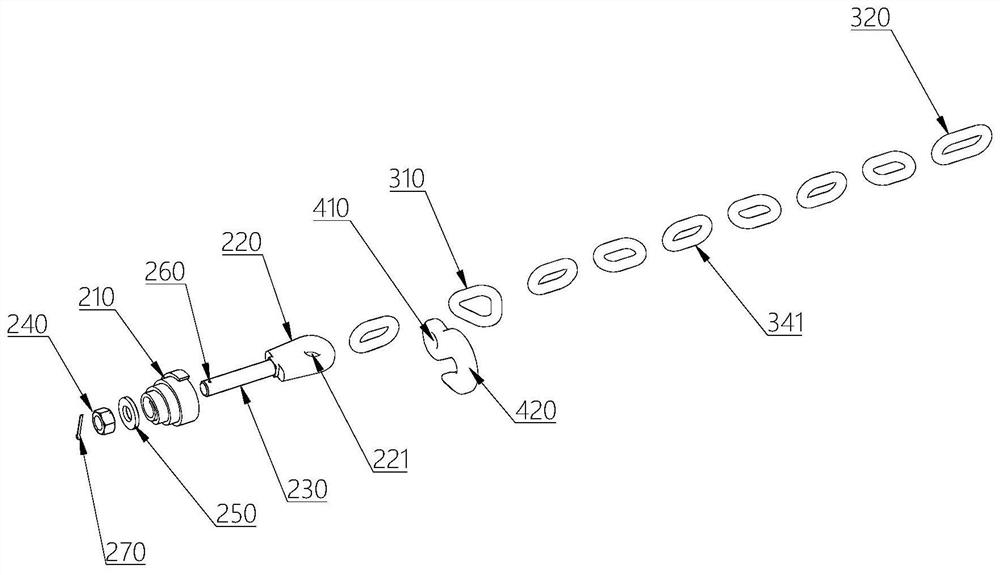

[0030] Such as Figure 1~2 As shown, the railway freight car emergency connecting device and its installation structure designed by the present invention include a fastener 200, a flexible connecting piece 300 and a towing hook 400. among them:

[0031] The fastener 200 is used to connect the end of the truck, and a buffer spring 210 is provided at the connection between the fastener 200 and the end of the truck, and a connecting hole 221 is provided at one end away from the end of the truck.

[0032] The first end of the flexible connecting member 300 is connected to the connecting hole 221 of the fastener 200, and a fixing ring 310 is provided near the end or the end; the second end or near the end of the flexible connecting member 300 is provided with a hanger. 接环320。 Connecting ring 320. The tail mounting hole 410 of the towing hook 400 is sleeved in the fixing ring 310, and the hook-shaped head 420 can be hooked in the hook ring 320 of another emergency connecti

Example Embodiment

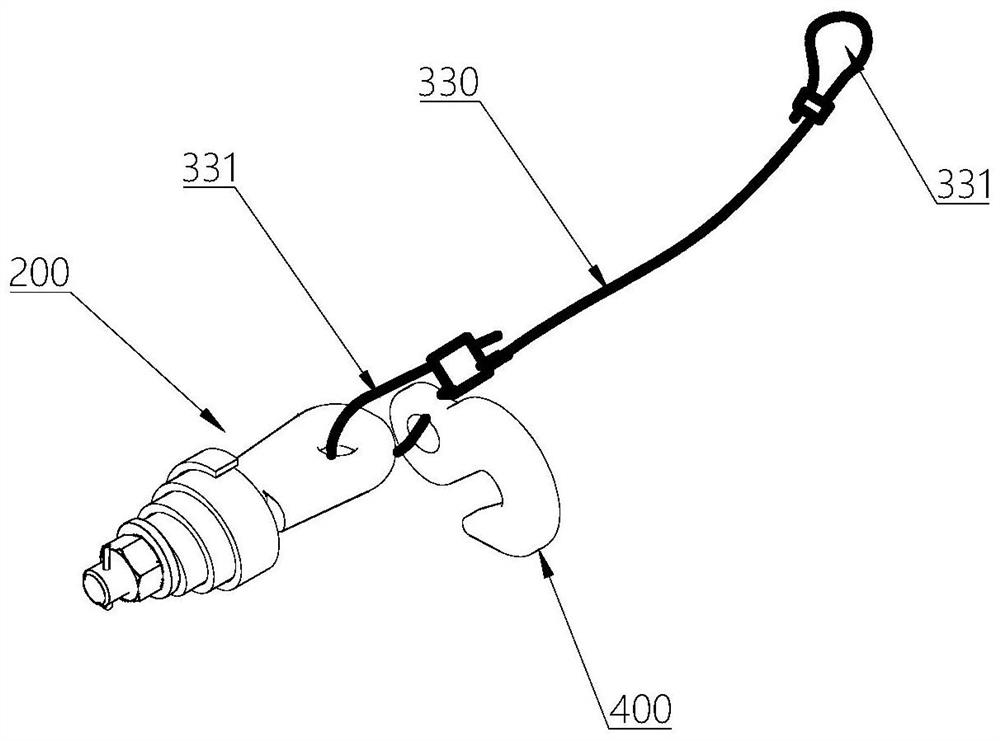

[0037] Example 2

[0038] Such as image 3 As shown, the emergency connecting device for railway freight cars designed in this embodiment uses a steel wire rope as the flexible connecting member 300. Both ends of the steel wire rope 330 are respectively wrapped around a set of rings 331 (fixed by a rope clamp), one of the rings 331 and the fastener 200 The connecting hole 221 is connected to the rear mounting hole 410 of the towing hook 400 as a fixing ring 310, and the other sleeve ring 331 is used as a hooking ring 320.

[0039] The rest is the same as in Example 1.

Example Embodiment

[0040] Example 3

[0041] Such as Figure 4-7 As shown, this embodiment provides the installation structure of the emergency connecting device for railway freight cars in Embodiment 1, including four emergency connecting devices arranged between two adjacent vehicles. The four emergency connection devices are divided into two groups, which are respectively located on one side of the main connection device 140 of two adjacent vehicles. The two emergency connecting devices in each group are respectively installed at the fastener installation holes 130 reserved for the end beam 100 of a car body through the fasteners 200 contained therein, and the respective towing hooks 400 are respectively hooked on each other 的mounted on the ring 320. The specific installation steps of the fastener 200 are as follows: after the screw 230 of the sheep-eye bolt passes through the fastener installation hole 130, the cushion spring 210 is placed on the inside of the vehicle, the washer 250 is installed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap