Electron transport material with core-shell structure and perovskite solar cell containing electron transport material

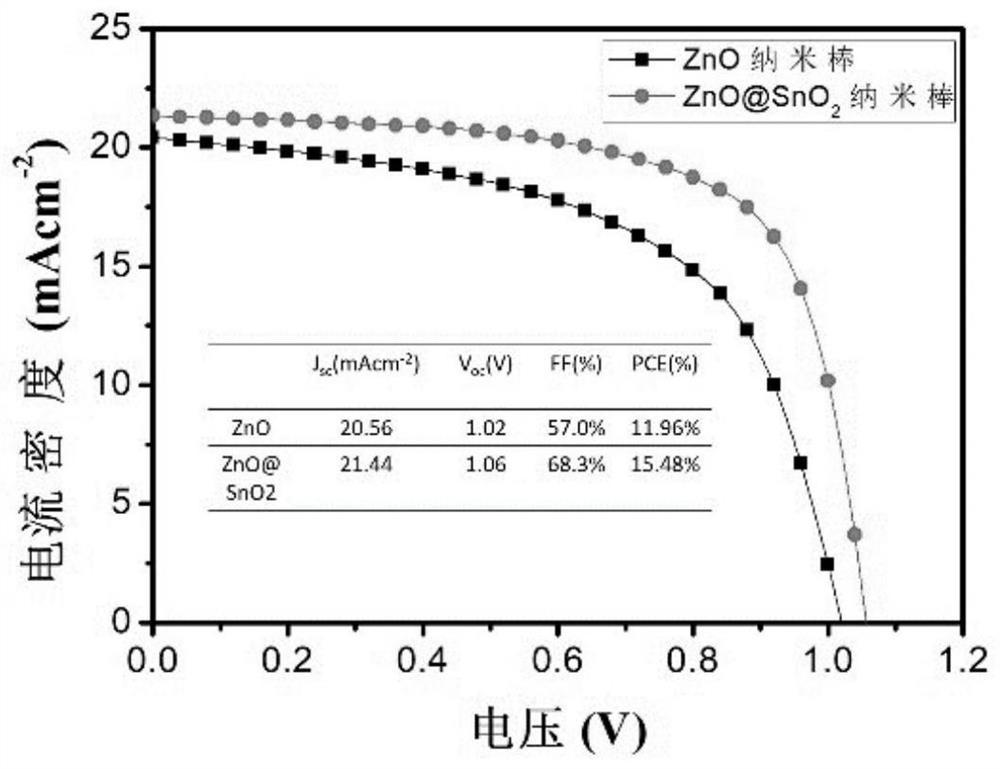

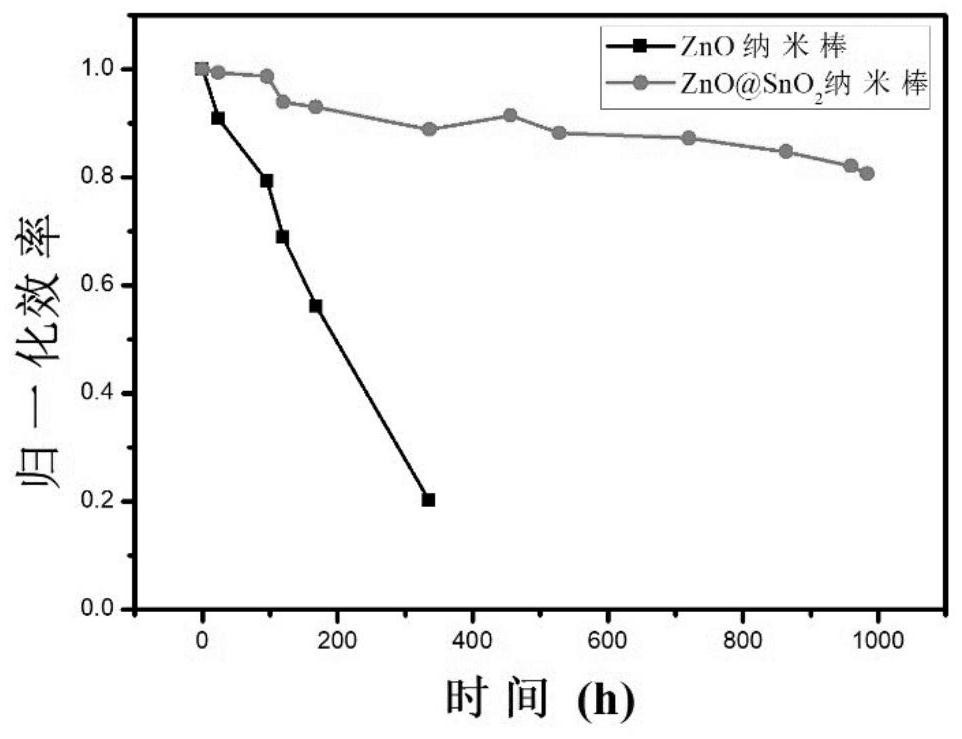

An electron transport material and solar cell technology, applied in the field of solar cells, can solve the problems of restricting commercial development and poor stability of perovskite cells, and achieve the effects of improving efficiency, improving stability, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

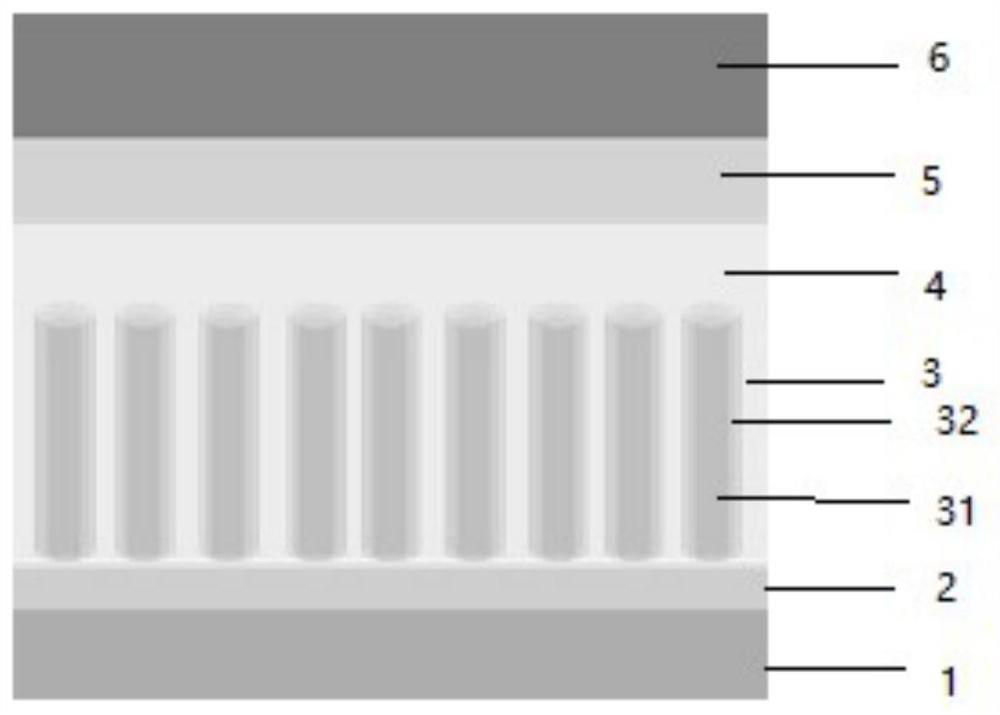

[0040] Example 1: ZnO@SnO 2 Fabrication of nanorod-based perovskite solar cells

[0041] 1) FTO glass cleaning: Sonicate the 2*2cm FTO glass substrate with detergent, deionized water, and alcohol for 20 minutes in sequence, and then N 2 blow dry.

[0042] 2) Preparation of the ZnO seed layer: use the sol-gel method to prepare a certain concentration of zinc acetate precursor solution as the ZnO seed solution, and then spin-coat the ZnO seed solution on the FTO substrate, the spin-coating speed is 3000rpm, and the spin-coating time for 20s. Then put it into the muffle furnace for annealing for a period of time.

[0043] 3) Preparation of ZnO nanorod arrays: prepared by chemical water deposition, first, prepare a growth solution, mix a certain concentration of zinc acetate aqueous solution and a certain concentration of polyvinylpyrrolidone (PVP) aqueous solution, and then adjust the mixed solution by dropping ammonia water The pH value is 10. Put the ZnO seed layer into the a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap