Liquid organic fertilizer prepared from kitchen waste, and production process thereof

A technology for kitchen waste and production process, which is applied in the field of preparing liquid organic fertilizer from kitchen waste and its production process, can solve the problems of reducing the quality of organic fertilizer, insufficient nutrition, consumption of substances, etc., so as to improve the fertilizer supply capacity and promote sufficient The effect of decomposing and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

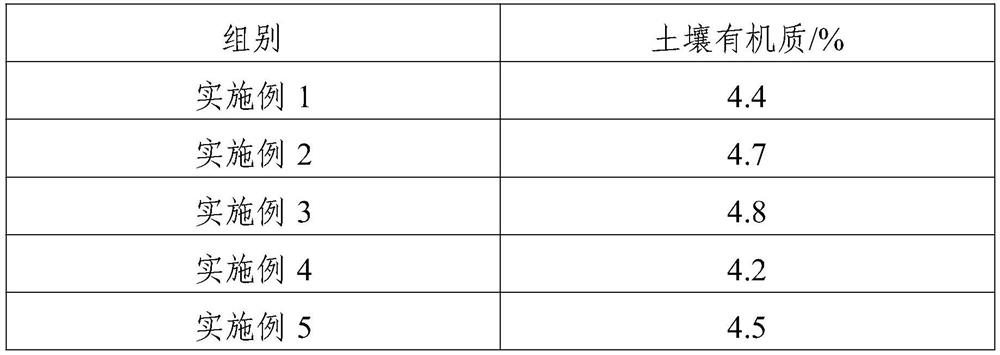

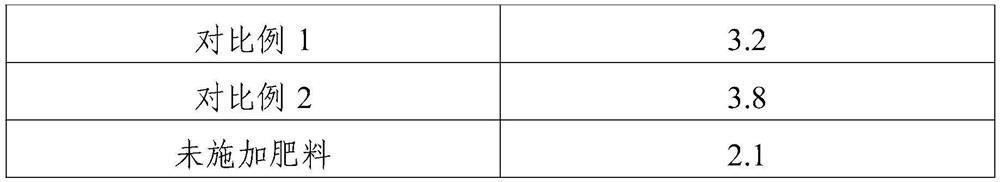

Examples

Embodiment 1

[0027] Prepare liquid organic fertilizer from food waste, including the following raw materials in parts by weight: 60 parts of food waste, 15 parts of straw, 2 parts of fermentation bacteria, 1 part of nitrogen-fixing bacteria, 0.5 parts of jelly-like bacillus, 0.2 part of purple bacteria, and supplement nutrients 3 parts, 10 parts potassium hydroxide solution, 4 parts weathered coal, 5 parts urea, 200 parts deionized water.

[0028] Fermentation bacteria include lactic acid bacteria, yeast and cellulolytic bacteria, and lactic acid bacteria, yeast and cellulolytic bacteria are mixed in a mass ratio of 2:1:1, and the live bacteria content of lactic acid bacteria is 1-2×10 8 CFU / g, the viable content of yeast is 1-4×10 8 CFU / g, the live bacteria content of cellulolytic bacteria is 1-5×10 8 CFU / g; nitrogen-fixing bacteria include Rhizobium and Azotobacter rotundum, and Rhizobium and Azotobacter rotundum are mixed at a mass ratio of 2:1, and the live bacteria content of Rhiz

Embodiment 2

[0035]Prepare liquid organic fertilizer from food waste, including the following raw materials in parts by weight: 62 parts of food waste, 16 parts of straw, 2.2 parts of fermentation bacteria, 1.1 parts of nitrogen-fixing bacteria, 0.6 parts of jelly-like bacillus, 0.3 parts of purple bacteria, and supplement nutrients 3.5 parts, 11 parts of potassium hydroxide solution, 5 parts of weathered coal, 6 parts of urea, and 220 parts of deionized water.

[0036] Fermentation bacteria include lactic acid bacteria, yeast and cellulolytic bacteria, and lactic acid bacteria, yeast and cellulolytic bacteria are mixed in a mass ratio of 2:1:1, and the live bacteria content of lactic acid bacteria is 1-2×10 8 CFU / g, the viable content of yeast is 1-4×10 8 CFU / g, the live bacteria content of cellulolytic bacteria is 1-5×10 8 CFU / g; nitrogen-fixing bacteria include Rhizobium and Azotobacter rotundum, and Rhizobium and Azotobacter rotundum are mixed at a mass ratio of 2:1, and the live b

Embodiment 3

[0043] Prepare liquid organic fertilizer from food waste, including the following raw materials in parts by weight: 65 parts of food waste, 17 parts of straw, 2.5 parts of fermentation bacteria, 1.3 parts of nitrogen-fixing bacteria, 0.7 parts of jelly-like bacillus, 0.4 parts of purple bacteria, and supplement nutrients 4 parts, 13 parts of potassium hydroxide solution, 6 parts of weathered coal, 8 parts of urea, and 270 parts of deionized water.

[0044] Fermentation bacteria include lactic acid bacteria, yeast and cellulolytic bacteria, and lactic acid bacteria, yeast and cellulolytic bacteria are mixed in a mass ratio of 2:1:1, and the live bacteria content of lactic acid bacteria is 1-2×10 8 CFU / g, the viable content of yeast is 1-4×10 8 CFU / g, the live bacteria content of cellulolytic bacteria is 1-5×10 8 CFU / g; nitrogen-fixing bacteria include Rhizobium and Azotobacter rotundum, and Rhizobium and Azotobacter rotundum are mixed at a mass ratio of 2:1, and the live ba

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap