Sliding assembly type building steel structure mounting construction method

A construction method and prefabricated technology, applied in building structure, on-site preparation of building components, construction, etc., can solve problems such as difficulty in accurately installing grids, low construction efficiency, and affecting construction safety, so as to facilitate installation and placement , Improve the installation firmness, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

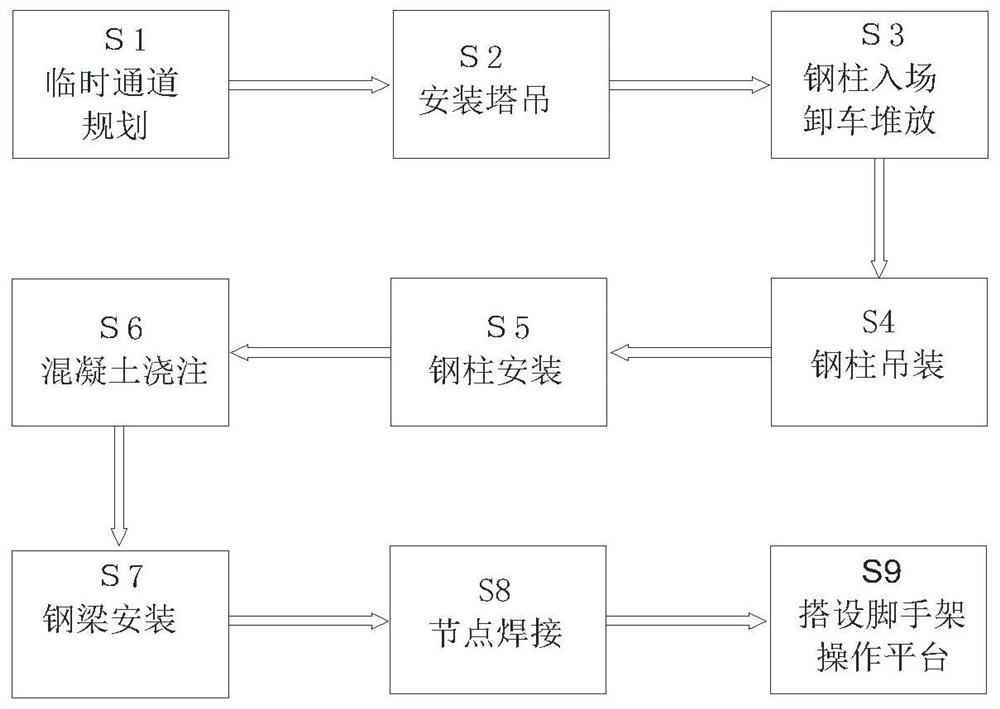

[0059] see Figure 1-12 , is a schematic diagram of the overall structure of a construction method for the installation and construction of a sliding assembly type building steel structure;

[0060] A method for installing and constructing a sliding-fabricated building steel structure, the method for installing and constructing a sliding-fabricated building steel structure comprises the following steps:

[0061] S1. Temporary passage planning: First, select an approach road near the construction site as a temporary passage for stacking steel structure materials, and plan an area near the approach road near the construction site for Temporary sites for storing steel roofing components;

[0062] S2. Installation of tower cranes: set up at least two tower cranes near the construction site to prefabricate and hoist the steel roof components stored in the temporary site in step S1. The two tower cranes are respectively located at two corners of the construction site so that the tower

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap