Dish-washing machine, control method and device of dish-washing machine and readable storage medium

A control method and technology for dishwashers, applied to devices and readable storage media, control methods for dishwashers, and the field of dishwashers, can solve problems such as poor disinfection effects of dishwashers, and achieve lower heat resistance requirements , Thoroughly disinfect the virus and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

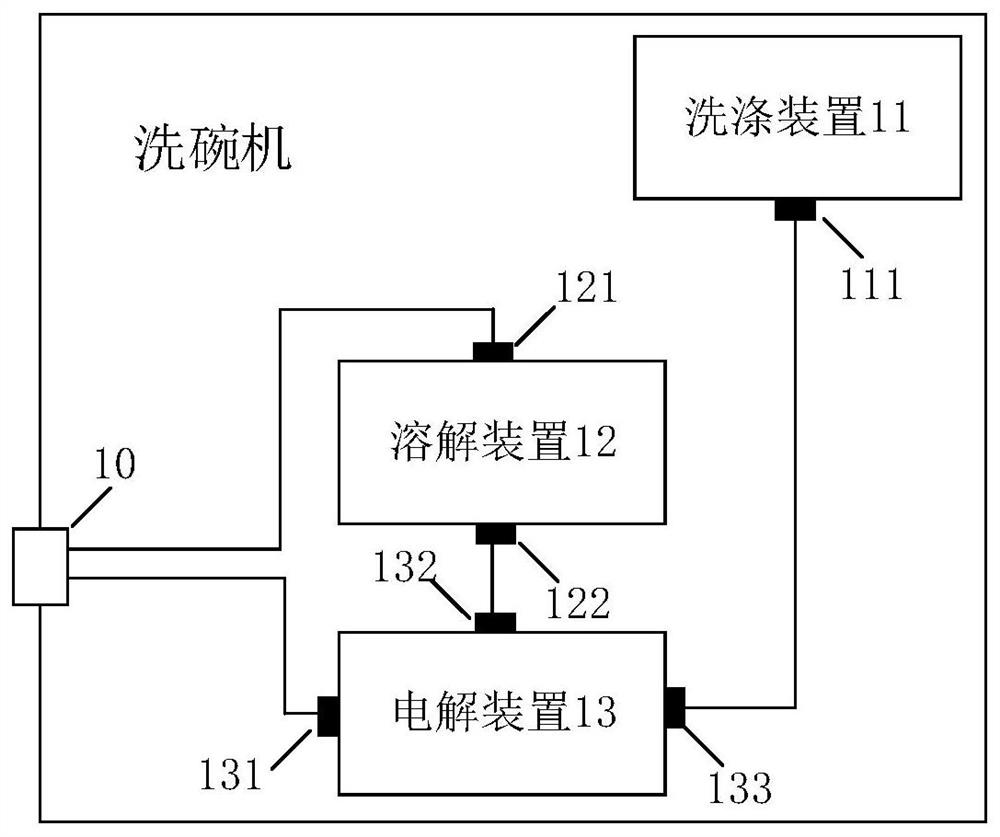

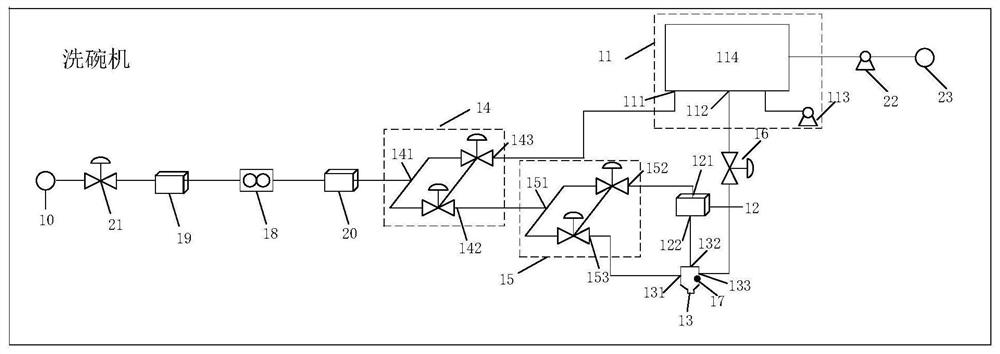

[0033] This embodiment provides a dishwasher to realize cleaning and disinfection of tableware and ensure safe use of tableware. Such as figure 1 As shown, the dishwasher includes a washing device 11 , a dissolving device 12 and an electrolysis device 13 . Wherein, the water inlet 121 of the dissolving device 12 is communicated with the water inlet 10 of the dishwasher through the first pipeline; the first water inlet 131 of the electrolysis device 13 is communicated with the water inlet 10 of the dishwasher through the second pipeline; The second water inlet 132 of 13 communicates with the water outlet 122 of the dissolving device 12 through a third pipeline; the water outlet 133 of the electrolysis device 13 communicates with the first water inlet 111 of the washing device 11 .

[0034] Exemplarily, the washing device is used for rinsing and cleaning tableware, the solution device is used for dissolving household water and solute to generate electrolyte, and the electrolysis d

Embodiment 2

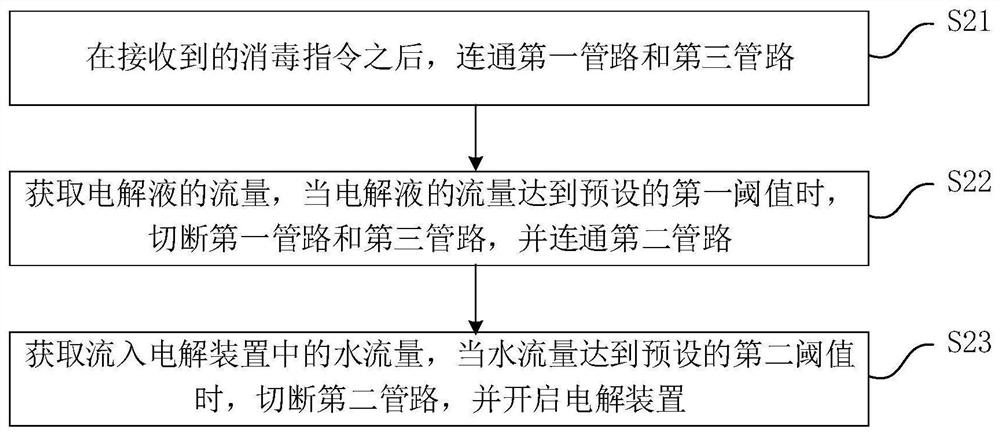

[0053] This embodiment provides a control method for a dishwasher, which is used in the dishwasher described in Embodiment 1, such as image 3 As shown, the control method of the dishwasher comprises the following steps:

[0054] S21, after receiving the disinfection instruction, connect the first pipeline and the third pipeline.

[0055] Exemplarily, for the specific description of the first pipeline and the third pipeline, refer to the relevant descriptions corresponding to the above embodiments, which will not be repeated here. When the dishwasher finishes cleaning the tableware and receives the disinfection instruction, it can control the opening of the first pipeline, so that water enters the dissolving device to dissolve the solute to generate a saturated electrolyte, and then open the third pipeline to pass the saturated electrolyte through the first The three pipelines lead to the electrolysis device.

[0056] S22. Obtain the flow rate of the electrolyte. When the flow

Embodiment 3

[0069] This embodiment provides a control device for a dishwasher, which is used in the dishwasher described in Embodiment 1, such as Figure 4 The controls for this dishwasher include:

[0070] The communication module 31 is configured to communicate with the first pipeline and the third pipeline after receiving the disinfection instruction. For details, refer to the relevant description of step S21 corresponding to the above method embodiment, which will not be repeated here.

[0071] The first control module 32 is used to obtain the flow rate of the electrolyte, and when the flow rate of the electrolyte reaches a preset first threshold, cut off the first pipeline and the third pipeline, and connect the second pipeline. For details, refer to the relevant description of the corresponding step S22 in the above method embodiment, which will not be repeated here.

[0072] The second control module 33 is used to obtain the flow of water flowing into the electrolysis device, and wh

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap