Instrument loading frame for logging truck

A technology for loading racks and instruments, applied in measurement, vehicle parts, transportation and packaging, etc., can solve the problems of short service life and poor effect, and achieve the effect of long service life, high safety and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

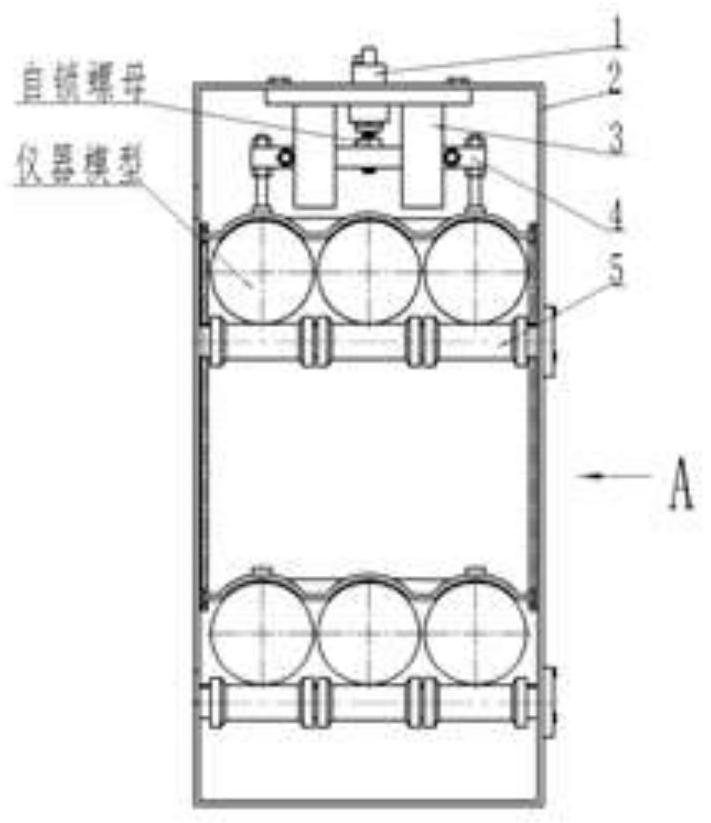

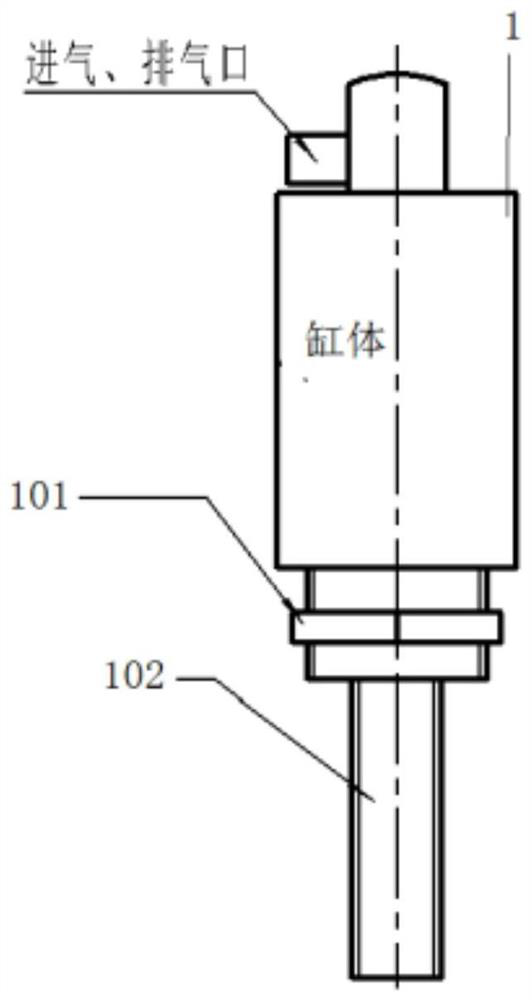

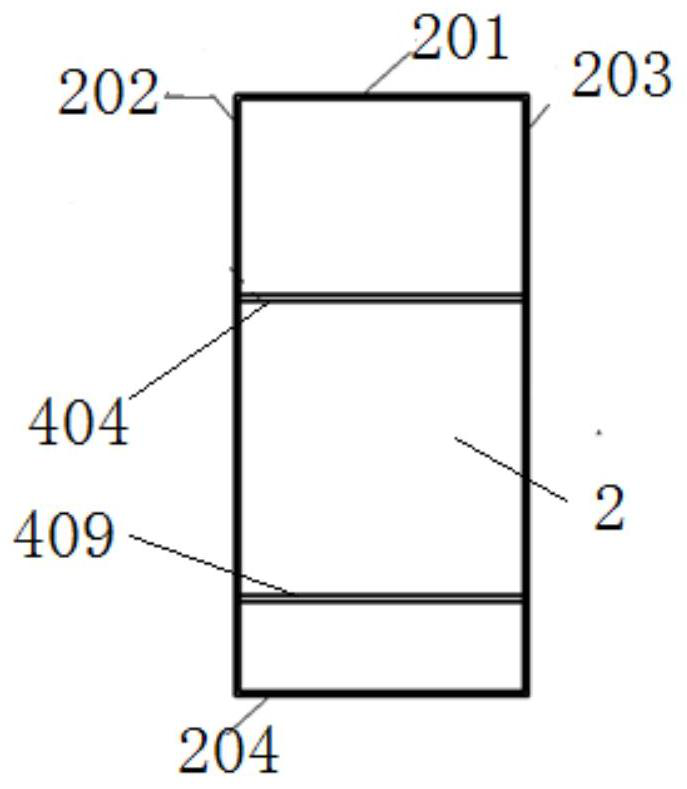

[0031] The invention provides an instrument loading frame for a well logging vehicle, such as figure 1 As shown, it includes an instrument loading frame body 2, and a counter torque guiding device 3 is installed on the top of the instrument loading frame body 2, and the anti torque guiding device 3 is located inside the instrument loading frame body 2, and also includes a self-resetting drive cylinder 1, The self-resetting drive cylinder 1 passes through the top of the instrument loading frame body 2 and is installed on the counter torque guiding device 3. An instrument pressing device 4 is hung on the end of the anti torque guiding device 3 far away from the instrument loading frame body 2, and the self-resetting driving One end of the cylinder 1 extending into the instrument loading frame body 2 is fixedly connected with the instrument pressin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap