Anti-pinch and emergency brake quick protection device for injection molding machine

An emergency braking, injection molding machine technology, applied in the direction of emergency protection circuit device, automatic disconnection emergency protection device, electromechanical device, etc. The effect of preventing casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

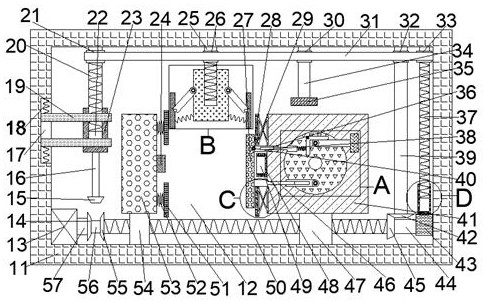

[0017]Combine belowFigure 1-5The present invention will be described in detail, in which, for the convenience of description, the following directions are specified as follows:figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

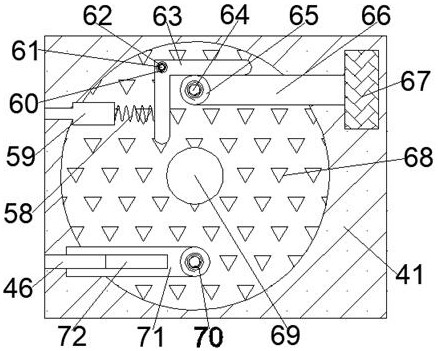

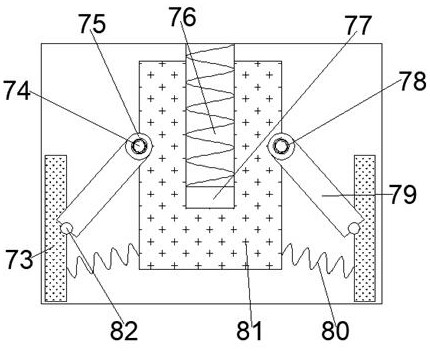

[0018]AttachedFigure 1-5The described device for preventing pinch and emergency braking of an injection molding machine includes an injection molding case 11 in which a processing cavity 12 with a forward opening is provided, and a lower wall of the processing cavity 12 is slidably connected with Positive threaded slider 47, the upper end of the positive threaded slider 47 is fixedly connected with an injection molding host 41, the front end of the injection molding host 41 is rotatably connected with a protruding shaft 69, and the protruding shaft 69 is fixedly connected on the outer peripheral surface There is a disc-shaped wheel 68. Two symmetrical embedded shafts 64 are rotatably connected in the front end

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap