Furniture production sawing machine capable of infrared induction

An infrared sensing and furniture technology, used in circular saws, manufacturing tools, sawing components, etc., can solve problems such as human injury and endanger the life of operators, and achieve the effect of improving safety and preventing casualties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

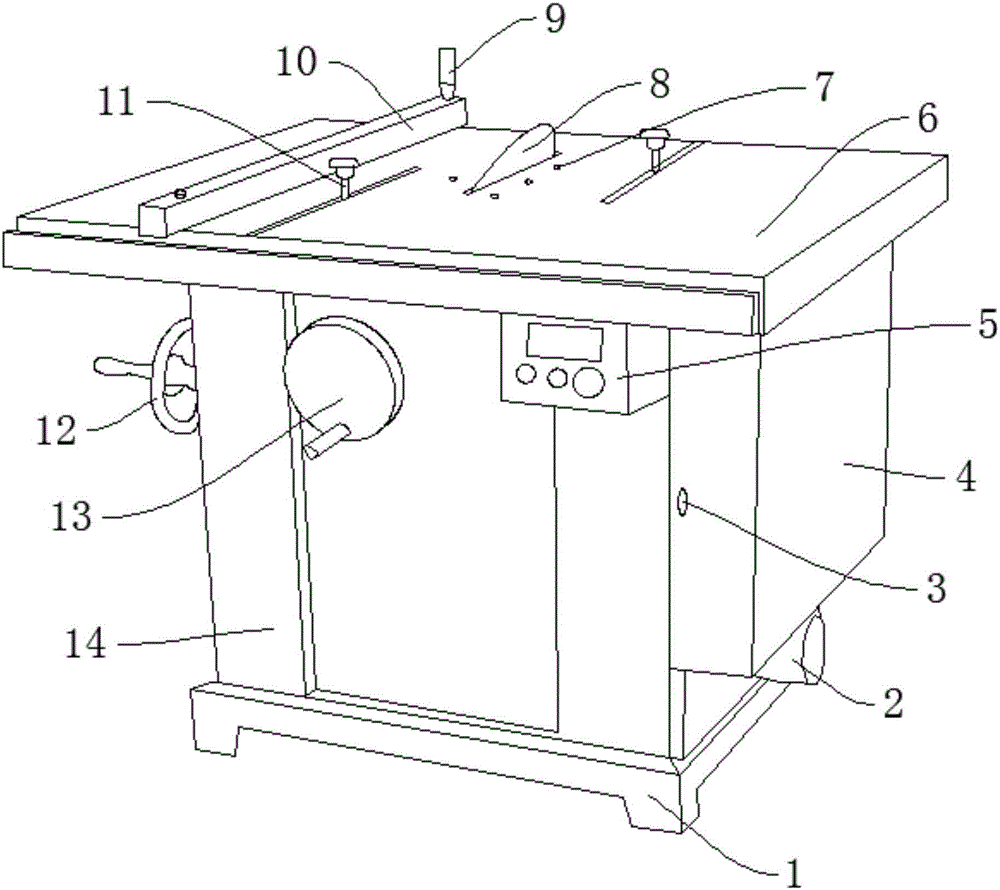

[0016] like figure 1 As shown, an infrared sensing sawing machine for furniture production includes a base 1, a transmission box 14, an electric control box 4 and a workbench 6. A transmission box 14 is provided next to the base 1, and the transmission box 14 is used for installation and operation. Panel 5, a longitudinal feed handwheel 13 is arranged beside the transmission box 14, the longitudinal feed handwheel 13 is used to drive the parts to perform longitudinal displacement, and a transverse feed handwheel 12 is arranged beside the longitudinal feed handwheel 13, and the transverse feed The handwheel 12 is used to drive the parts to move laterally, a worktable 6 is arranged beside the transmission box 14, the worktable 6 is used to place the work parts, and a limit rod 10 is set next to the worktable 6, and the limit rod 10 is used to facilitate the positioning of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap