Method for integrally renewing deck of oil tanker in floating state

A technology for decks and oil tankers, applied to warships, etc., can solve the problems of long docking period, large engineering volume, and insufficient overall strength of the hull, and achieve the effect of saving docking period and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

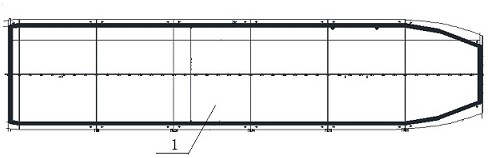

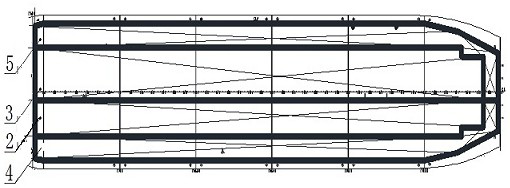

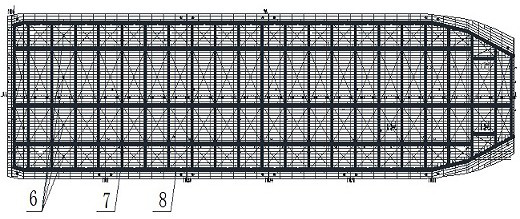

[0022] Such as Figure 1 to Figure 6 As shown, the method for overall deck renewal of an oil tanker in a floating state is a process method for deck renewal of an oil tanker in a floating state, which includes the following steps: a. The deck renewal area 1 of the original ship is designed in stages, which is divided into four phases in total , and calculate the overall strength and load adjustment according to the phased design, and use the OUTOSHIP software to model and calculate the overall stability and load adjustment calculation; b. According to the phased design, design and renew the deck section 6; c. Oil tanker floating dock 11 , into the ballast tank 9 in the central area with a corresponding amount of ballast water 10, using a temporary submersible pump placed in the sea to inject sea water into the ballast tank in the central area, the amount of water injected is about 1500 tons; d, dismantling the original ship of the first phase Deck, and install the first phase of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap