Oxygen production rate control method and system, air conditioner, computer equipment, medium and terminal

A rate control and air conditioning technology, applied in the field of oxygen production rate control, medium and terminal, which can solve the problems of large power consumption of air conditioners, difficulty of air conditioners to meet the needs of users, and reduction of oxygen concentration in the indoor environment, so as to achieve the effect of satisfying oxygen concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

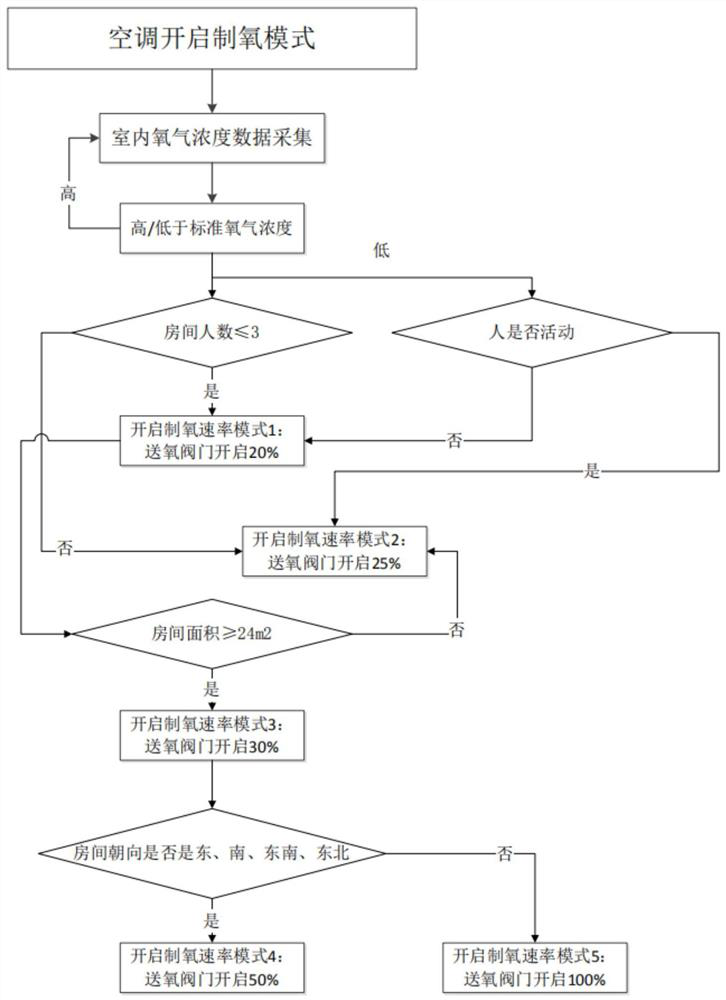

[0033] Aiming at the problems existing in the prior art, the present invention provides a method for controlling the oxygen production rate. The present invention will be described in detail below with reference to the accompanying drawings.

[0034] The invention can adjust the oxygen production rate mode after feedback according to the room area, orientation, number of people in the room and the active situation, so as to ensure that the oxygen concentration in the room in the oxygen production mode meets the user's requirements.

[0035] The air conditioner oxygen production rate mode of the present invention inclu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap