GaN-based echo wall laser based on porous DBR, and preparation method and application thereof

A laser and whispering gallery technology, applied in the field of laser light sources, can solve the problems of increasing the difference in refractive index of the vertical interface, small contact area, leakage of support materials, etc., and achieve the effect of low threshold power density, excellent heat dissipation performance, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

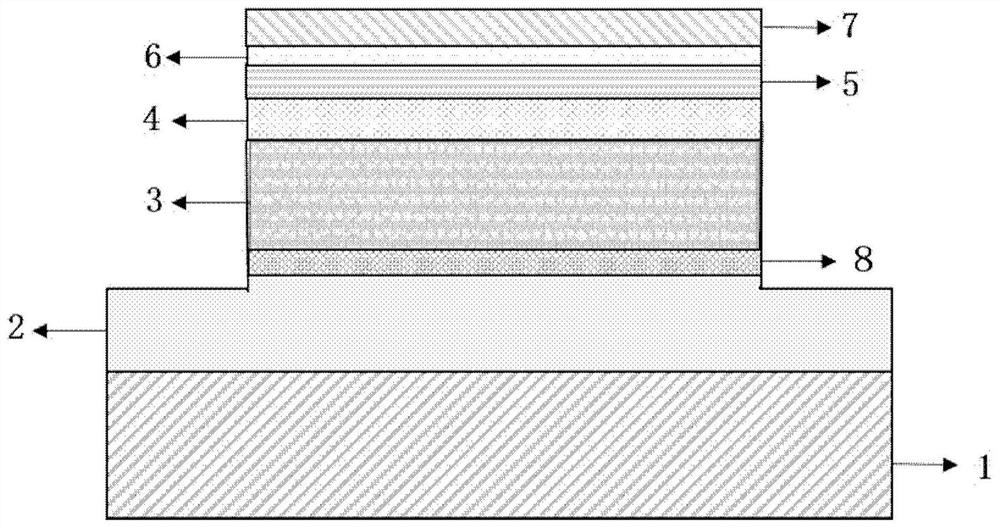

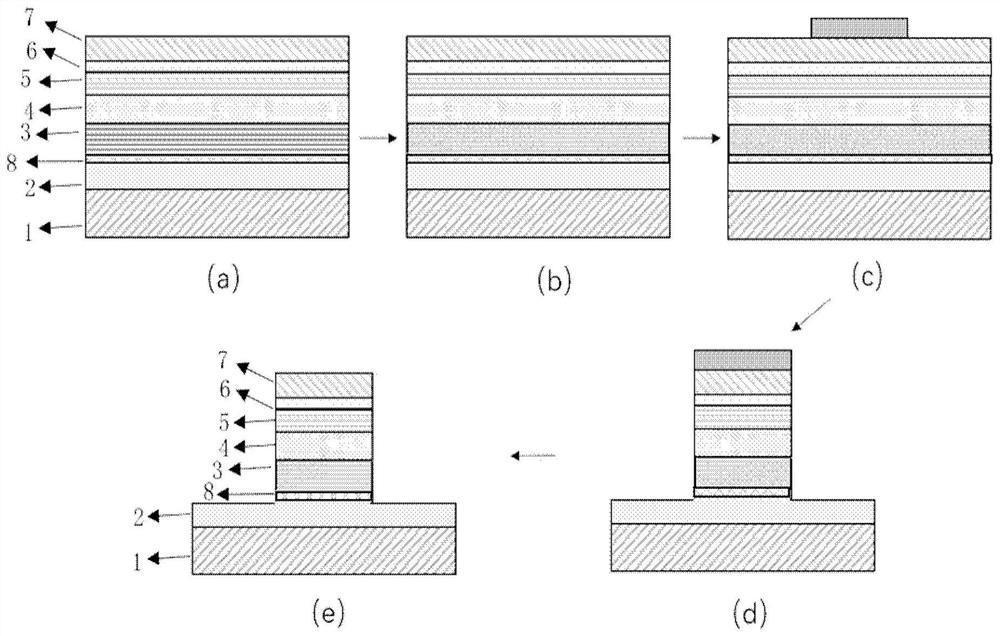

[0050] The present invention also discloses a preparation method of the above-mentioned laser, comprising:

[0051] (1) sequentially growing buffer layers, alternately stacked doped layers, n-type doped GaN layers, active layers, electron blocking layers and p-type doped GaN layers on the substrate;

[0052] (2) performing lateral etching on alternately stacked doped layers to form a porous DBR layer;

[0053] (3) a mask plate is set on the top of the device obtained in step (2);

[0054](4) using the mask plate obtained in step (3) as a template to etch the p-type doped GaN layer, the electron blocking layer, the active layer, the n-type doped layer, the porous DBR layer to the buffer layer;

[0055] (5) removing the mask in step (4), and the obtained device is the laser.

[0056] Wherein, the corrosion method described in the step (2) to form the porous DBR layer comprises the use of electrochemical corrosion;

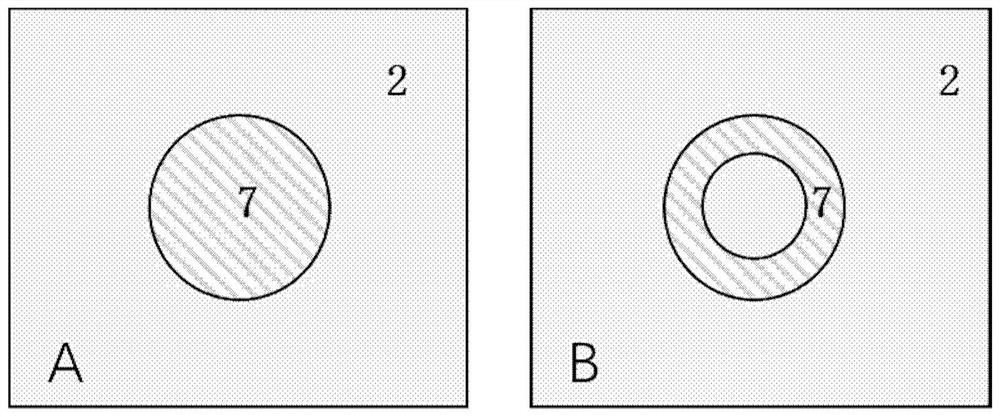

[0057] Wherein, the pattern shape of the mask plate described i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap