Kitchen waste leachate treatment and utilization device

A technology of kitchen waste and leachate, which is applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, water treatment under temperature conditions, etc. It can solve the problems of low resource recovery rate, high operating cost, and long processing time. , to achieve the effect of strengthening the degradation efficiency, improving the activity of anaerobic bacteria, and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

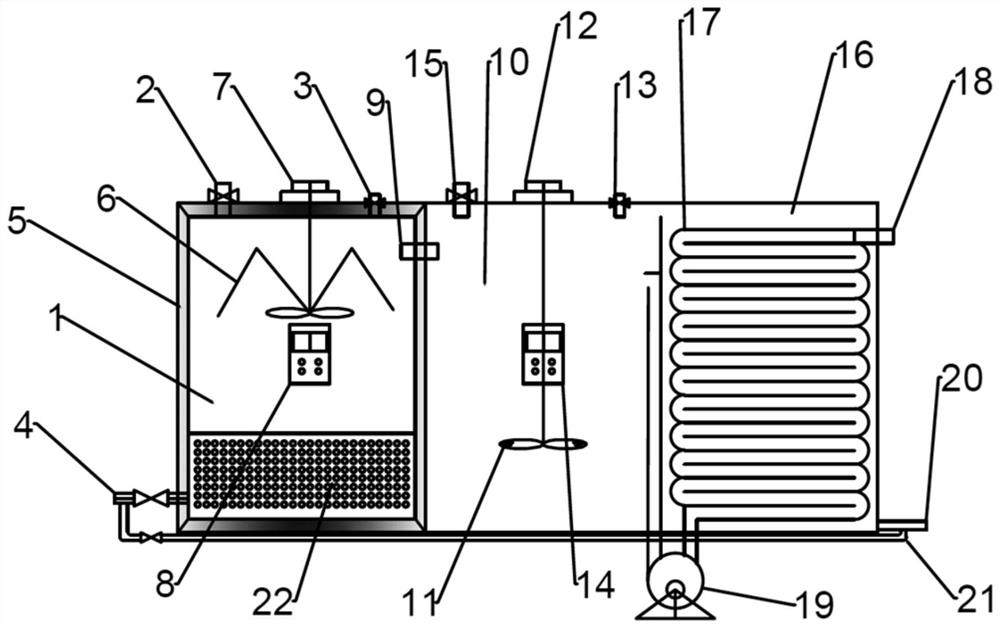

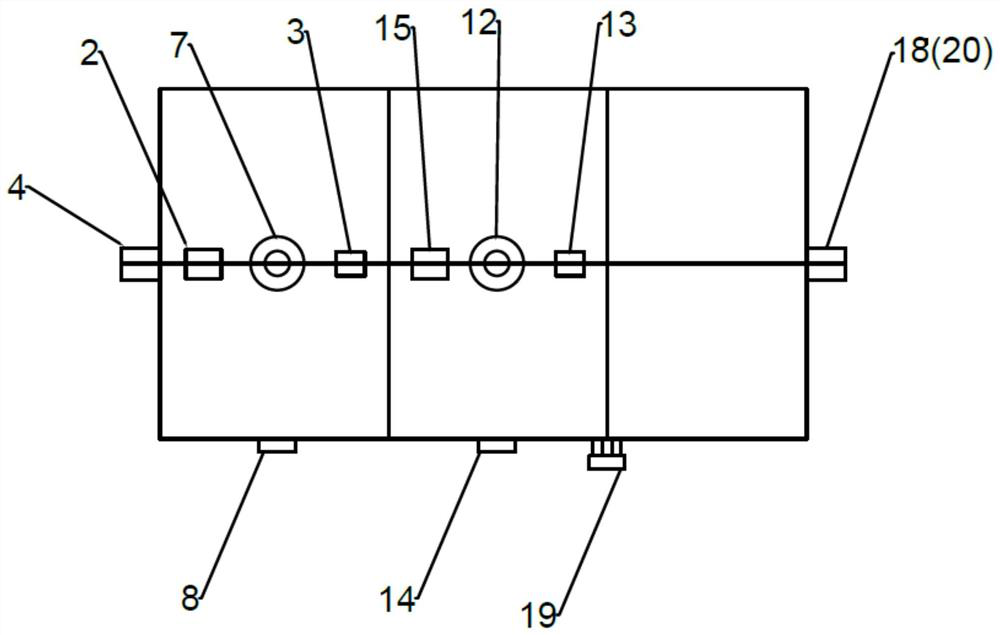

[0022] Such as figure 1 and 2 As shown, the kitchen waste leachate treatment and utilization device of the present invention includes three parts: a high-temperature anaerobic digestion bin 1 , an anoxic reaction bin 10 , and a membrane separation bin 16 .

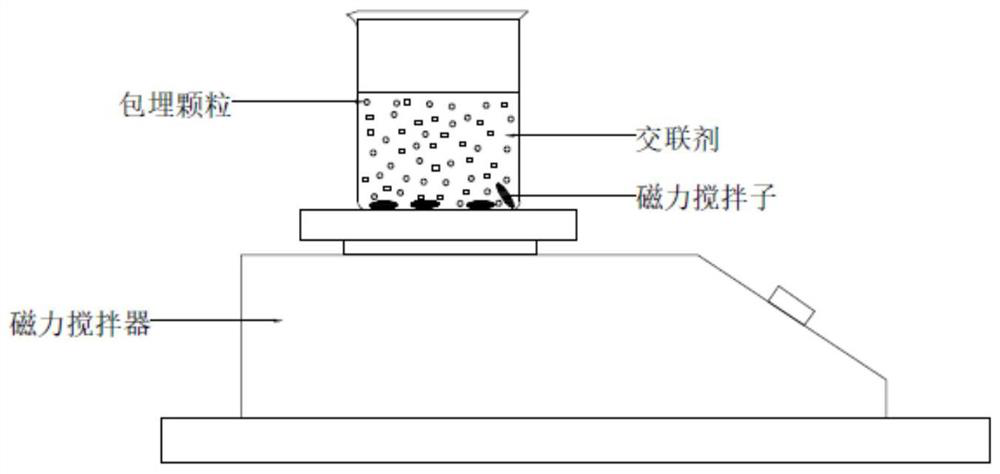

[0023] Wherein, a water inlet 4 is provided on the bottom side of the high-temperature anaerobic digestion chamber 1 , and the water inlet 4 communicates with a clean water return pipe 21 . The bottom of the high-temperature anaerobic digestion chamber 1 is provided with an isolation area, and the interior of the isolation area is filled with PVA-SA immo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap