Integrated display screen complete machine

A display screen and integrated technology, which is applied in the field of integrated display screens, can solve the problems of failure to effectively use the best way of the whole machine, difficulty in satisfying the integration effect of the whole machine, inconvenient mold opening and assembly, etc., to achieve Improve product stability and firmness, improve space utilization, and reduce mold opening costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025]In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions of the embodiments of the present invention will be described in contemplation in conjunction with the drawings of the embodiments of the present invention. Obviously, the described embodiments are the embodiments of the present invention, not all of the embodiments. All other embodiments obtained by those of ordinary skill in the art are within the scope of the present invention based on the embodiments of the invention described herein.

[0026]The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

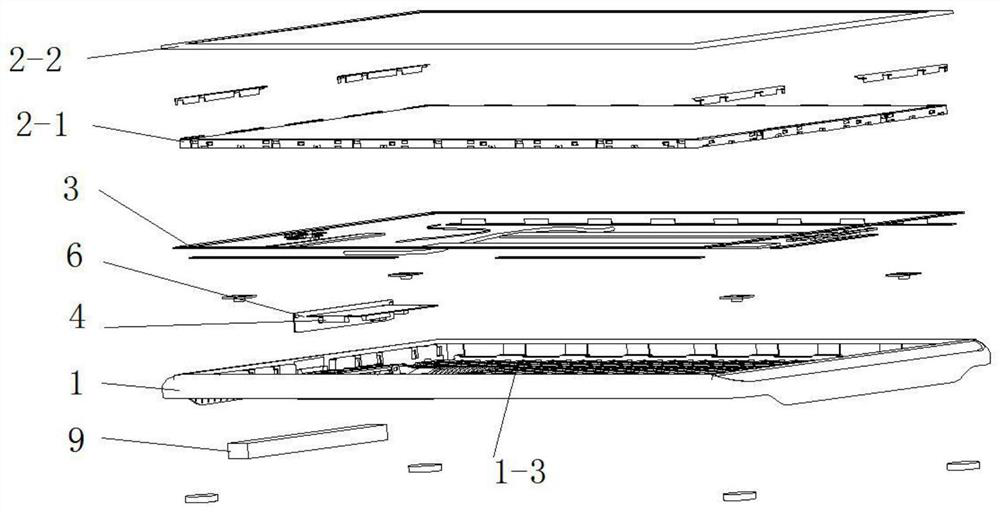

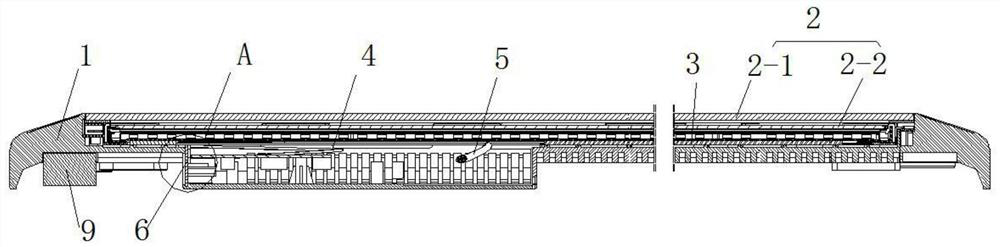

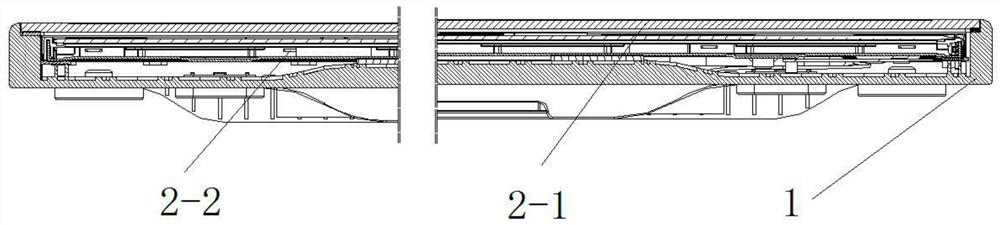

[0027]Such asFigure 1-5As shown, as a first embodiment of the present invention, an integrated display screen, including a housing body 1, a display screen assembly 2, and the display module 2-1, and the display module 2-1 and The tempered glass layer 2-2 provided in the upper end su

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap