Device and method for online pre-judging ultralow-temperature valve leakage through temperature difference

A technology of ultra-low temperature and valves, which is applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of inconvenience of regular off-line maintenance, hidden safety hazards, losses, etc., and achieve the effect of reducing environmental pollution and safety hazards, and avoiding emergency repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

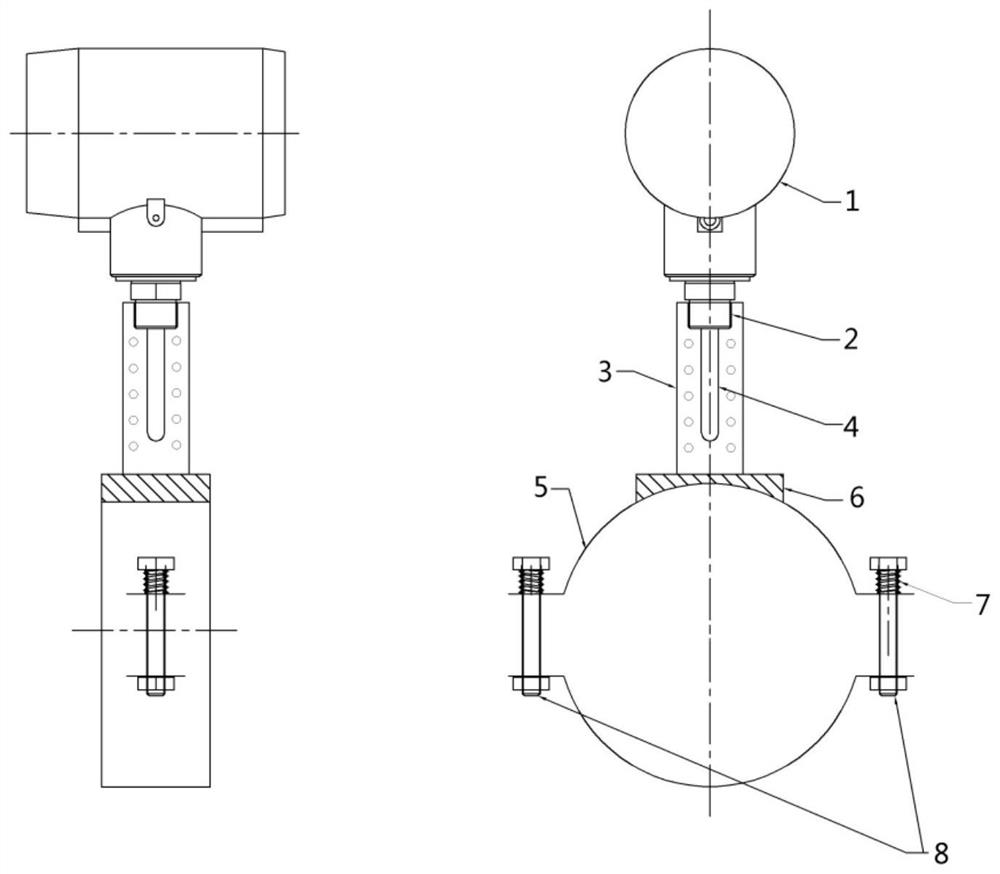

[0033] In one embodiment of the present invention, as figure 1 As shown, a device for online prediction of ultra-low temperature valve leakage through temperature difference, including: meter head 1, temperature measuring parts and assembly parts, the meter head 1 is equipped with power supply equipment inside, with temperature display, 5G transmission and explosion-proof functions; The temperature part is connected to the side of the meter head 1 through the connection port 2; the assembly part is connected to the side of the temperature measuring part away from the meter head 1 through the base 6, and the assembly part is connected to the outer wall of the valve cover, mainly used for connecting with the valve After the outer wall of the cover is fitted, the temperature of the outer wall of the valve cover is measured.

[0034] Such as figure 1 As shown, th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap