Edible starch producing and processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

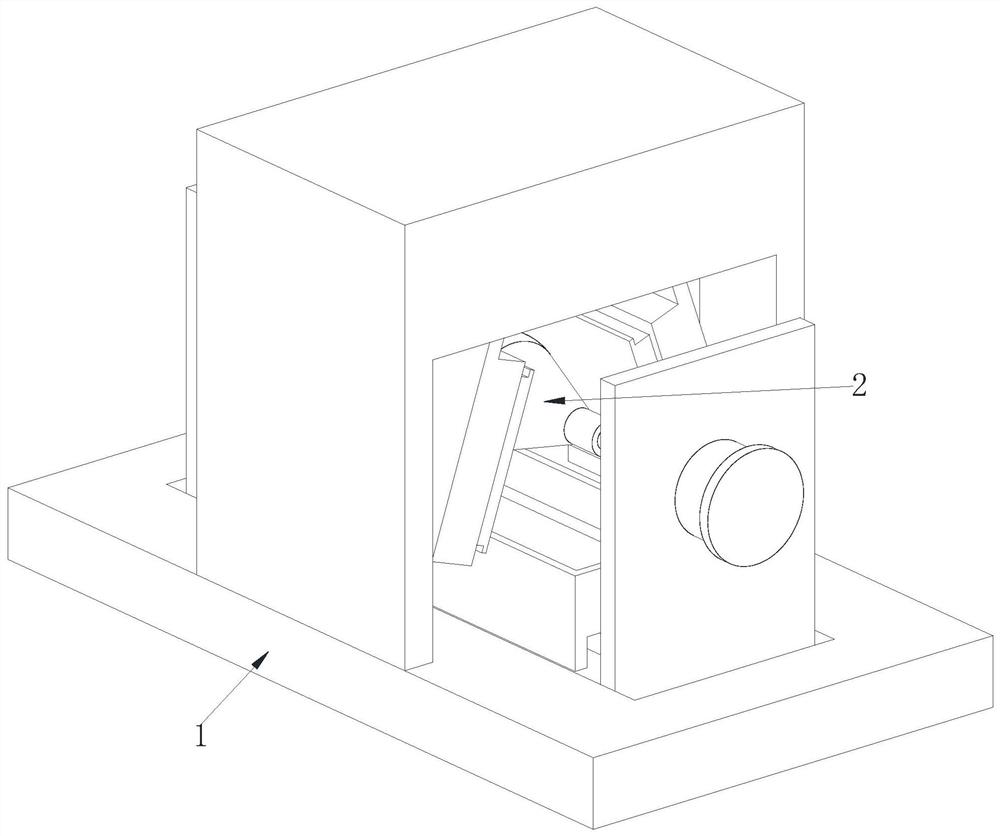

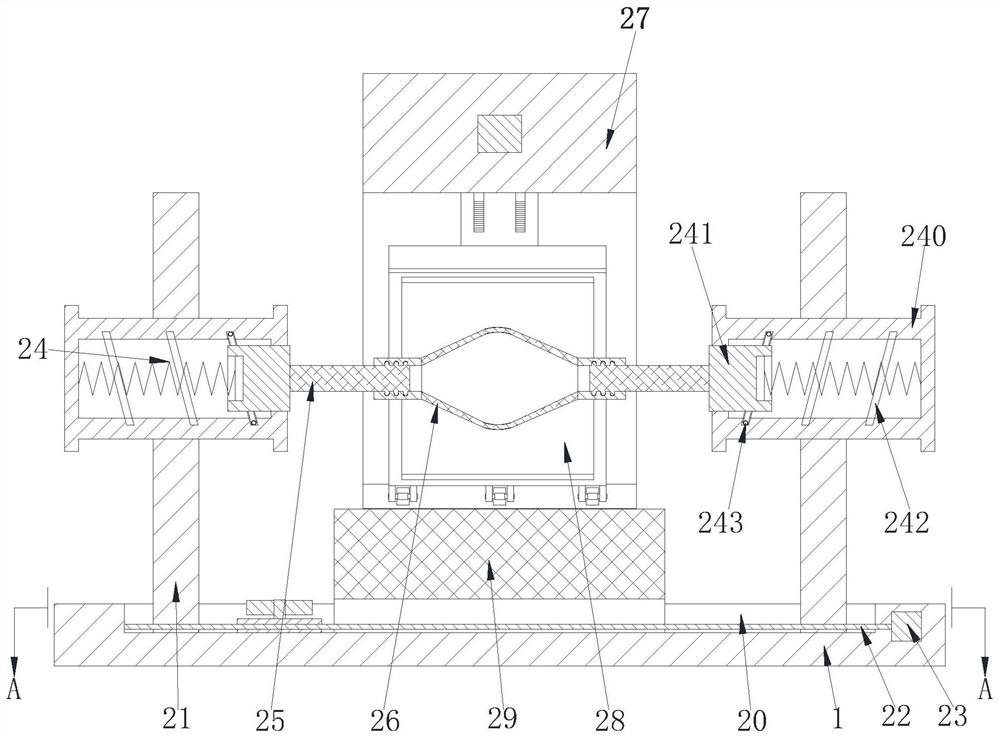

[0034] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

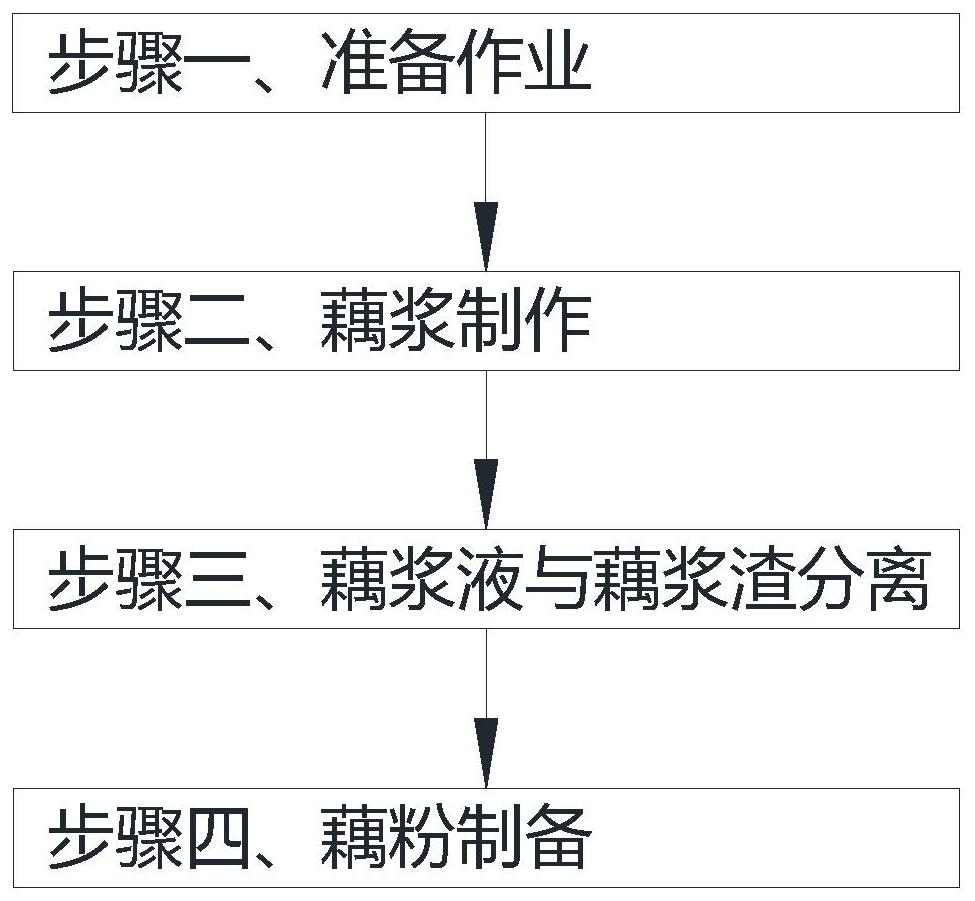

[0035] A method for producing and processing edible starch, which uses a production and processing equipment for edible starch, the equipment for producing and processing edible starch includes a base 1 and a filter device 2, the specific method when using the above equipment for producing and processing edible starch to produce and process edible starch lotus root powder as follows:

[0036] Step 1, preparatory work: before the edible starch lotus root powder is produced and processed, the edible starch production and processing equipment of the present invention is debugged;

[0037] Step 2. Production of lotus root pulp: first clean the surface of the dug out lotus root, then cut off the joints and rotten tips of the lotus root, and remove the oute

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap