Labeling mechanism for reagent bottles

A reagent bottle and labeling technology, applied in the field of labeling equipment, can solve the problems of poor uniformity, unsightly products, no reagent bottle adjustment, etc., and achieve the effect of ensuring the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

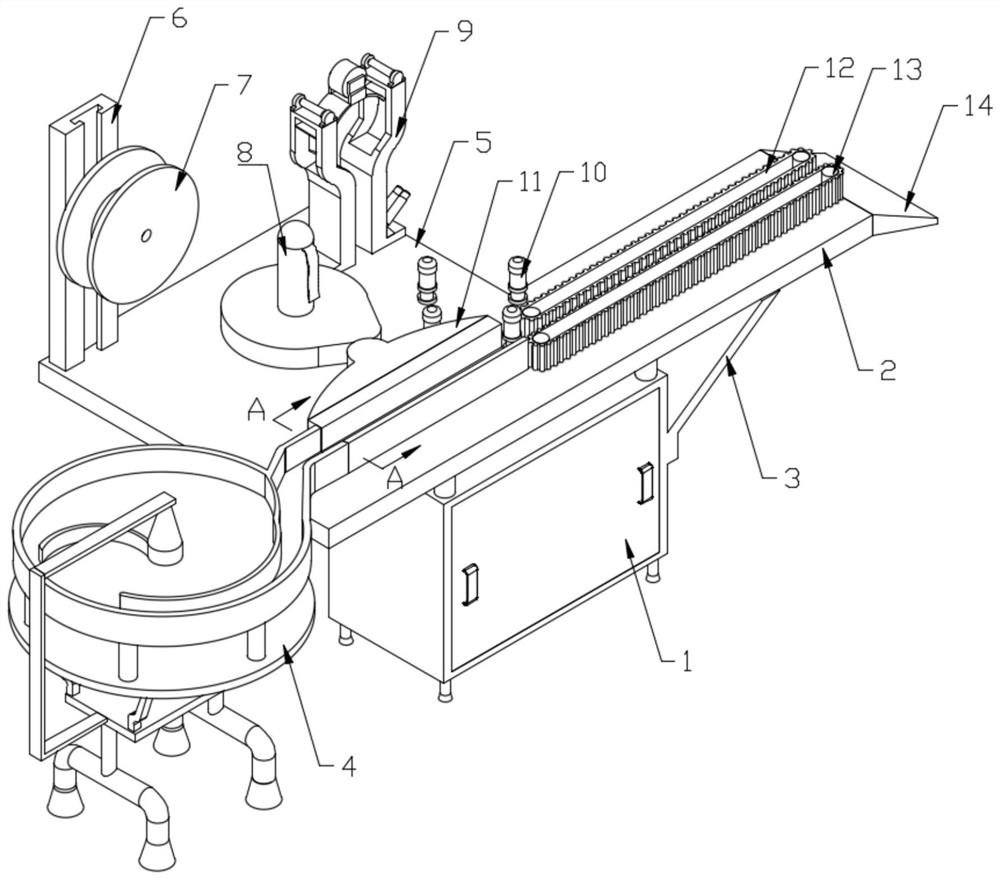

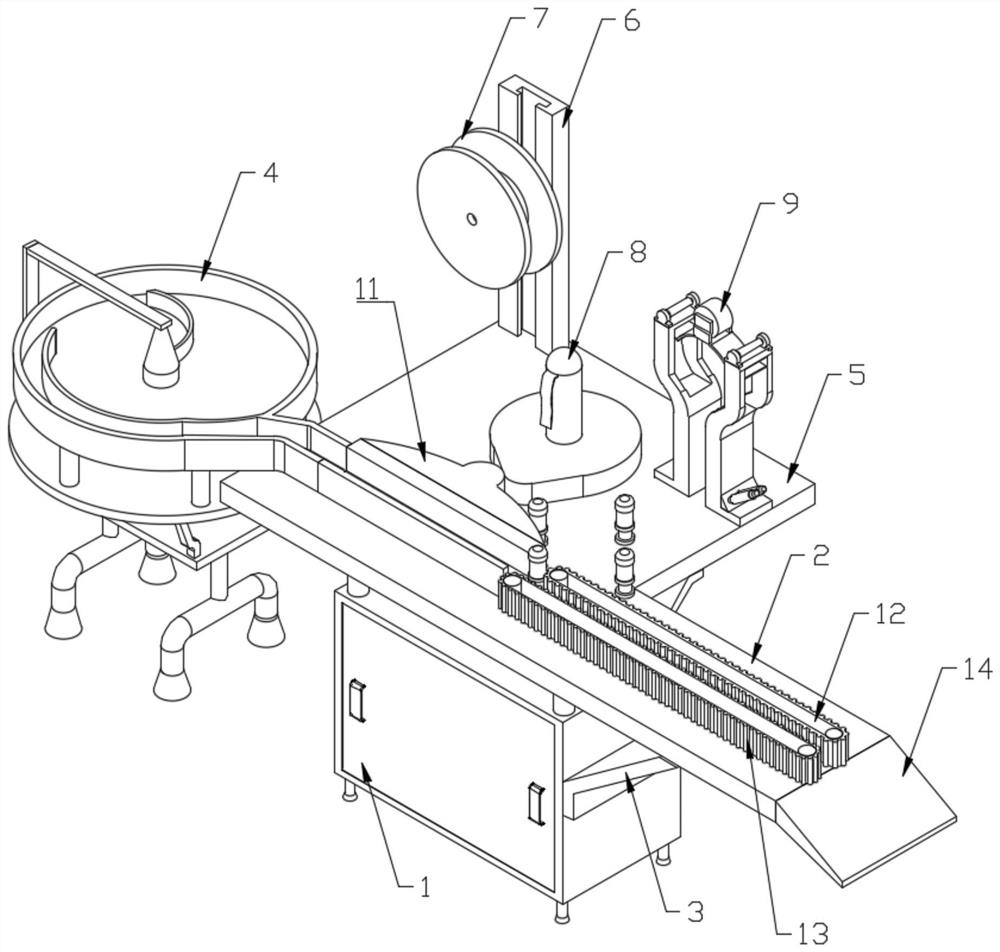

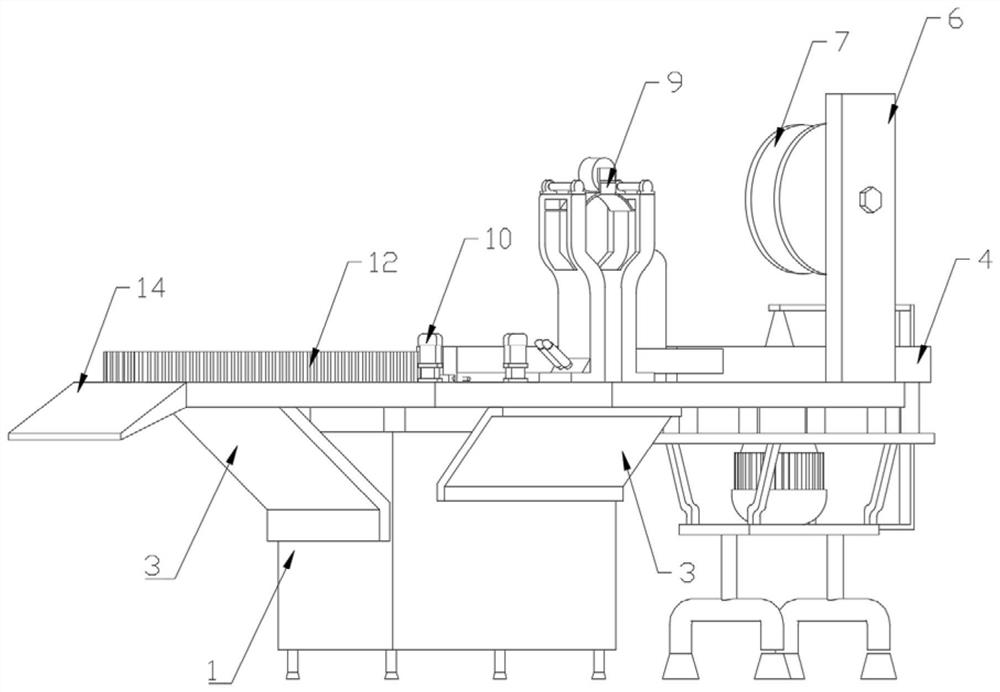

[0037] Attached below Figure 1-8 The present invention is further described with embodiment:

[0038]A labeling mechanism for reagent bottles, comprising a cabinet body 1, the bottom of the cabinet body 1 has four legs, and the top of the cabinet body 1 is horizontally fixed with a workbench 2; the bottom of the workbench 2 The support frame 3 is fixedly connected with the cabinet body 1; the rear side of the workbench 2 is also fixedly installed with a mounting table 5; the bottom of the mounting table 5 is fixedly connected with the cabinet body 1 through the support frame 3; the described One end of the workbench 2 is fixedly equipped with a reagent bottle lead-out plate 14, and the end of the workbench 2 far away from the reagent bottle lead-out plate 14 is provided with a reagent bottle arrangement transmission mechanism 4; the installation platform 5 is fixedly installed with a sliding mounting frame 6; The sliding mounting frame 6 is slidably connected with an unwinding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap