Method for automatically adjusting Fenton process parameters based on PH and ORP linkage

A technology of automatic adjustment and process parameters, applied in chemical instruments and methods, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problem of low COD degradation efficiency and achieve the effect of good COD degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for automatically adjusting Fenton process parameters based on PH and ORP linkage disclosed in the present application, comprising the following steps:

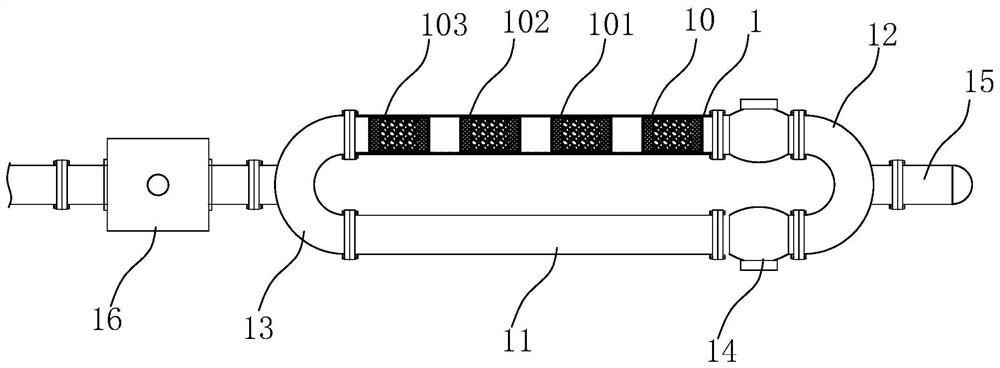

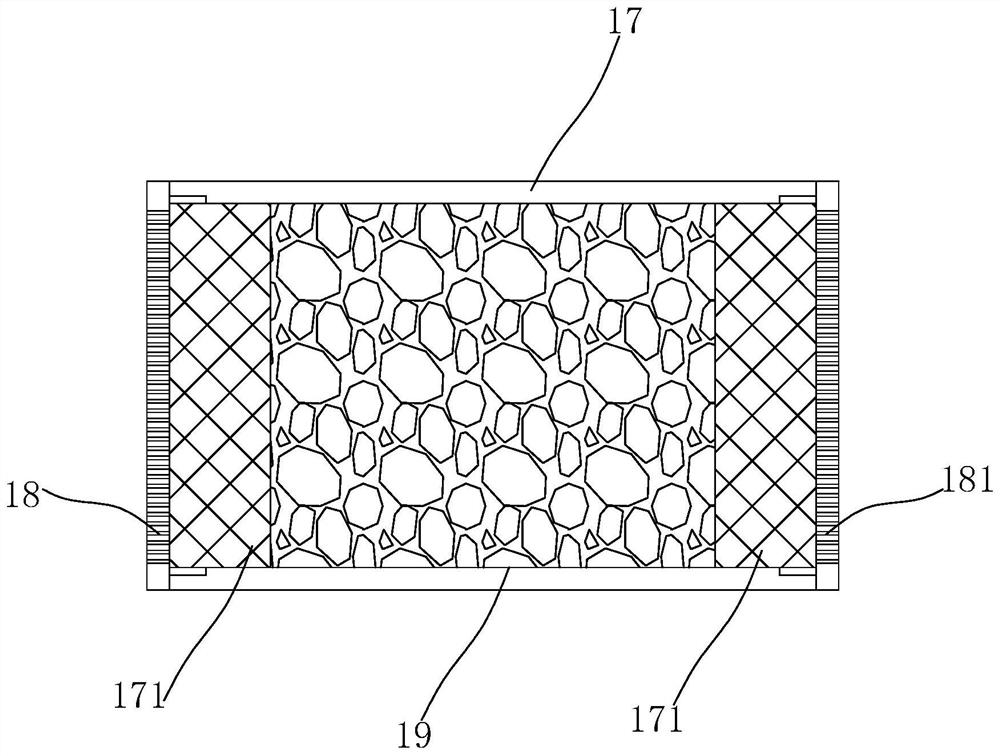

[0048] Step 1: The printing and dyeing textile wastewater (derived from the sewage discharged by a dyeing and finishing enterprise in an industrial park in Zhejiang) is subjected to the following pretreatments in sequence, hydrolytic acidification treatment, A2O method treatment, secondary sedimentation tank treatment, the water body in the secondary sedimentation tank Filtration treatment is carried out through a combined filter body. The pretreatment time is 5-6 hours. The pretreated sewage is pumped into the water quality adjustment tank for standby. The COD value of the wastewater in the water quality adjustment tank is tested to be 313mg / L, and the chroma is 161 times. SS index is 41mg / L;

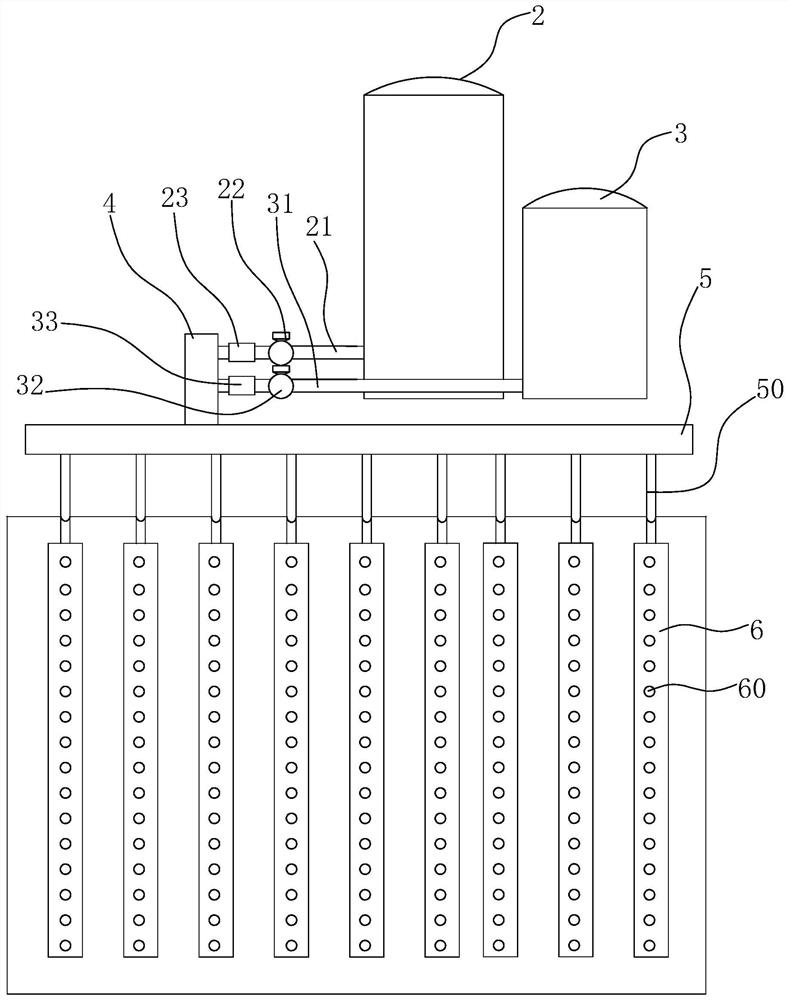

[0049] Step 2, the wastewater in the water quality adjustment tank is pumped into the dosing mixing tank, and 12% s

Embodiment 2

[0055] A method for automatically adjusting Fenton process parameters based on PH and ORP linkage disclosed in the present application, comprising the following steps:

[0056] Step 1: The printing and dyeing textile wastewater (derived from the sewage discharged by a dyeing and finishing enterprise in an industrial park in Zhejiang) is subjected to the following pretreatments in sequence, hydrolytic acidification treatment, A2O method treatment, secondary sedimentation tank treatment, the water body in the secondary sedimentation tank Filtration treatment is carried out through a combined filter body. The pretreatment time is 5-6 hours. The pretreated sewage is pumped into the water quality adjustment tank for standby. The COD value of the wastewater in the water quality adjustment tank is tested to be 321mg / L, and the chroma is 163 times. SS index is 45mg / L;

[0057] Step 2, the wastewater in the water quality adjustment tank is pumped into the dosing mixing tank, and 12% s

Embodiment 3

[0063] A method for automatically adjusting Fenton process parameters based on PH and ORP linkage disclosed in the present application, comprising the following steps:

[0064] Step 1: The printing and dyeing textile wastewater (derived from the sewage discharged by a dyeing and finishing enterprise in an industrial park in Zhejiang) is subjected to the following pretreatments in sequence, hydrolytic acidification treatment, A2O method treatment, secondary sedimentation tank treatment, the water body in the secondary sedimentation tank Filtration treatment is carried out through a combined filter body. The pretreatment time is 5-6 hours. The pretreated sewage is pumped into the water quality adjustment tank for standby. The COD value of the wastewater in the water quality adjustment tank is tested to be 304 mg / L, and the chroma is 158 times. SS index is 45mg / L;

[0065] Step 2, the wastewater in the water quality adjustment tank is pumped into the dosing mixing tank, and 12%

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap